Common targets and corresponding color

1. Golden Color Series

Ti series:

Ti TiN

Ti+Au TiN+Au

Ti+Zr TiZrN

Other:

Zr ZrN

Zr+Au ZrN+Au

Hf HfN

2.Black Color Series

Ti series:

Ti TiCN

Ti (C, O)

TiAl TiAlN

Ti50Al50 black

Ti30Al70 dark

TiAl (C, O, N)

Other:

Si SixNy

CrAl CrAlC

SUS SUSC

DLC

Nb NbOx

The Ti-Al alloy target is usually used as a functional film. When it is used as decoration, there are several problems:

- the film itself has high internal stress, so it has poor adhesion to the three dimensional surface of the workpiece.

- The proportion of Ti and Al in the target is difficult to be realized in the production of the target material, which is expected to be in the circle. The equipment of the target is realized by adjusting the sputtering power ratio between the two targets of Ti and Al in the vacuum chamber, and greatly reducing the cost of the target.

3.Blue Color Series

Interference Color:

Ti, Cr, Zr, Al, In

Other:

TiAl TiAlN

SUS SUSN

4.Rare elements boride and its color:

ZrB2 silver grey

ZrB12 silver grey

ZrBN silver grey

LaB6 deep violet

CeB6 blue

SmB6 blue

YB6 silver grey

5.Rare element carbides and their colors:

BeC red

MnC black

NbC light tea color

TaC all brown

LaN black

HfN yellowish brown

WN Brown

MnN black

The production of target materials and their compounds is the most widely used in Ti, Cr, Ni and other targets, and then into nitrogen and acetylene to form some colors. Therefore, the process adjustment is the most convenient way for the development of the sputter target color.

PVD couplet:

The color of the film formed by the interaction of grain boundaries, or the interaction of free electrons and photons, is strongly dependent on the chemical composition and grain structure of the film.

The microstructure of the film is highly disordered and the grain is nanoscale, and some micro defects, such as holes, interstitial atoms, and impurities, lead to their electronic properties, and the corresponding optical properties are different from those of the bulk materials.

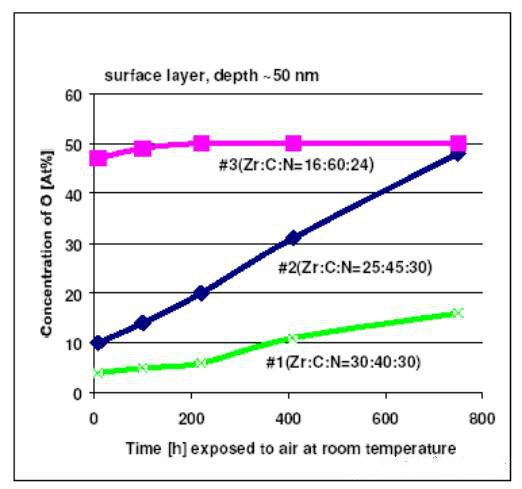

Color stability of PVD targets film (as an example of ZrN)

The longer the exposure time of the coated products in the air is, the more serious the oxidation is, especially for the smaller proportion of metal elements in the coating.

Stanford Advanced Materials (SAM) Corporation is a global sputtering target manufacturer established in 1994. For more information, please visit https://www.sputtertargets.net/.