1. Introduction: The Versatile Role of ZnS in Modern Industries

Zinc Sulfide (ZnS) is a widely used material in high-tech industries, from semiconductors to advanced optical coatings. Known for its unique physical and chemical properties, ZnS has become essential in modern technology.

This material has a high refractive index, excellent optical clarity, and strong thermal stability. These features make ZnS valuable in precision optics and electronic components. In fields like military, aerospace, and high-precision optical devices, the demand for ZnS continues to grow.

In this article, we’ll explore the key qualities of ZnS and how it serves various industries. For more details, check out our Zinc Sulfide Evaporation Materials for specific applications.

2. Key Properties of ZnS: Why Choose Zinc Sulfide?

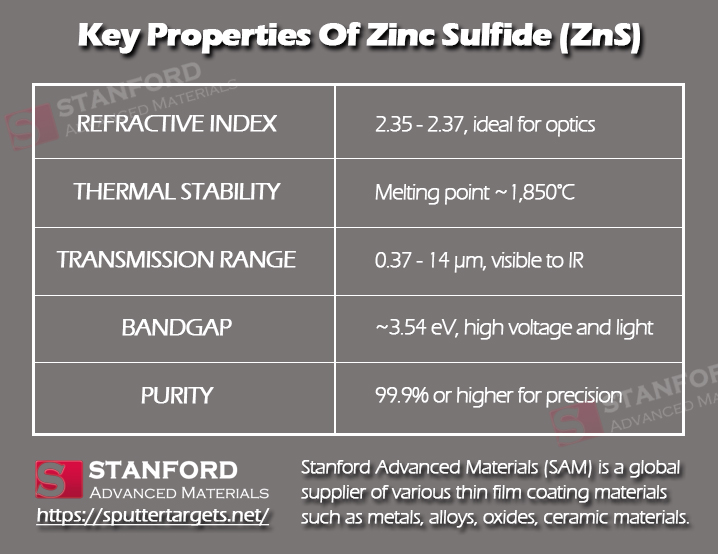

Zinc Sulfide (ZnS) has unique properties that make it valuable in high-tech industries. For example, its refractive index ranges from 2.35 to 2.37 in the visible light spectrum, which enhances optical performance in coatings and lenses. This high refractive index allows ZnS to create clear, accurate images, making it a preferred material in optical lenses and displays.

ZnS also withstands high temperatures, with a melting point around 1,850°C. This thermal stability is essential for industries where materials face extreme conditions. ZnS is also highly transparent to visible light, with a transmission range of 0.37 to 14 micrometers, which covers most visible and near-infrared light. This feature is ideal for display technologies and various optical applications.

These specific qualities make ZnS a reliable choice for applications that require both precision and durability, from advanced optics to industrial electronics.

3. Applications of ZnS in the Semiconductor Industry

In the semiconductor industry, Zinc Sulfide (ZnS) is widely used due to its stability and electrical properties. ZnS is often employed as a material for thin-film transistors and light-emitting diodes (LEDs). Its ability to handle high temperatures without breaking down makes it an excellent fit for these components.

ZnS is also valued for its bandgap, which is approximately 3.54 eV. This wide bandgap allows ZnS to perform well in high-voltage environments and under intense light. Its durability and transparency make it suitable for displays, sensors, and optical storage devices that require stable, long-lasting materials.

ZnS’s combination of optical and electronic qualities makes it an important material in the growing semiconductor field, where precision and reliability are key.

4. ZnS in the Optics Industry: A Top Choice for High-Tech Coatings

In the optics industry, Zinc Sulfide (ZnS) is highly valued for its role in advanced coatings. Its high refractive index (2.35 to 2.37) and excellent transparency make it a popular choice for optical coatings, such as those on lenses, mirrors, and windows. ZnS coatings enhance clarity and precision, which is essential in applications requiring accurate light transmission.

ZnS is also widely used in infrared (IR) optics. With a transmission range extending from 0.37 to 14 micrometers, ZnS effectively covers both visible and infrared light. This makes it ideal for applications in thermal imaging, night vision devices, and other systems that rely on IR light.

ZnS’s ability to perform well under varying light conditions and its durability make it a preferred material in optical and infrared coating applications. It enables devices to deliver high-quality images while maintaining long-term performance, even in challenging environments.

5. Key Role of ZnS in Military and Aerospace Applications

Zinc Sulfide (ZnS) is also vital in military and aerospace applications. Due to its durability and optical clarity, ZnS is commonly used in night vision systems and infrared windows. Its wide transmission range, covering visible to infrared wavelengths (0.37 to 14 micrometers), makes it perfect for these high-tech uses. ZnS enables clear vision in low-light and thermal imaging scenarios, which are critical in defense and surveillance operations.

ZnS can also withstand harsh environmental conditions, including extreme temperatures and pressure. This resilience is essential in aerospace applications, where materials face intense physical demands. For example, ZnS coatings on infrared sensors and targeting systems help improve the accuracy and reliability of these devices in challenging conditions.

With its unique blend of strength and optical qualities, ZnS plays a crucial role in enhancing the performance and durability of equipment in these demanding fields.

6. How to Choose High-Quality ZnS Materials

Choosing the right Zinc Sulfide (ZnS) material depends on a few key factors. First, consider the purity of the ZnS. High-purity ZnS (typically 99.9% or higher) is essential for applications that demand precision, like optical coatings and electronic components.

Second, evaluate the particle size. For evaporation coatings, fine ZnS particles are preferred, as they help achieve a smoother and more uniform coating. This is crucial in industries that rely on clear, high-quality optics or thin-film layers.

Finally, assess the material’s thermal stability. ZnS used in high-temperature processes must withstand extreme conditions without degrading. Ensuring the ZnS material you choose meets these requirements will help achieve the best performance and longevity in your applications.

To explore our range of reliable, high-purity ZnS options, visit the Zinc Sulfide Evaporation Materials page for more details.

7. Conclusion: The Future of ZnS in Modern Technology

Zinc Sulfide (ZnS) continues to prove its value across various high-tech industries. From semiconductors to military optics, ZnS’s unique properties—high refractive index, thermal stability, and wide light transmission range—make it a critical material. As technology advances, the demand for reliable, high-quality ZnS materials will likely grow, especially in sectors that rely on precision and durability.

Whether for advanced optics, semiconductor applications, or aerospace technology, ZnS plays an essential role in improving performance and efficiency. By understanding its diverse applications and selecting the right ZnS materials, businesses can stay at the forefront of technological innovation. Companies like Stanford Advanced Materials (SAM) continue to provide high-quality ZnS materials that support a range of industries, ensuring reliable supply and consistent quality.