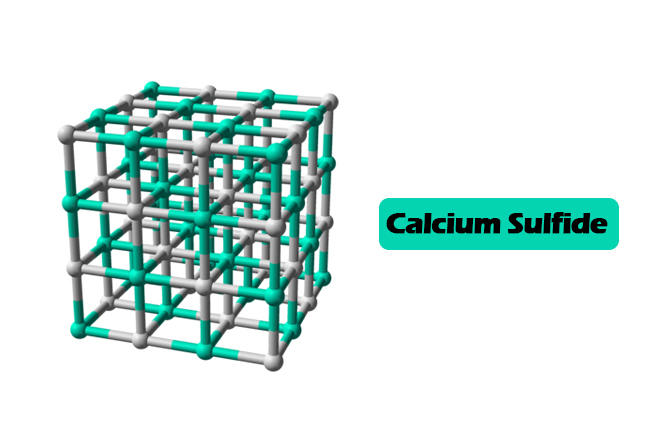

Introduction: The Unique Value of CaS in Modern Industries

Calcium Sulfide (CaS) is a versatile material with a range of applications across high-tech industries. Known for its stability and unique properties, CaS is used in everything from electronics to environmental technology. Its high thermal stability, chemical resistance, and transparency make it an excellent choice for a variety of applications.

In this article, we’ll look at the top five industrial applications of CaS, highlighting its value in fields like photonics, chemistry, and environmental protection. With each application, we’ll see how CaS has become an important material in modern science and industry.

1. CaS in Photonics and Display Technology

Calcium Sulfide (CaS) is popular in photonics and display technology. Its unique optical properties make it an excellent material for light-emitting diodes (LEDs) and display screens. CaS efficiently absorbs and emits light, which improves the brightness and clarity of modern displays. This property is especially useful for screens where high color accuracy is important, such as televisions, monitors, and handheld devices.

In LEDs, CaS helps fine-tune the color of light emitted. It allows manufacturers to control color output more precisely, creating vivid, lifelike images. CaS is also stable at higher temperatures, making it suitable for display components that generate heat. This stability helps ensure long-lasting performance in electronics that need reliable light quality over time.

By enhancing color accuracy and durability, CaS plays a key role in creating high-quality screens and displays.

2. CaS in Chemical Synthesis and Catalysis

Calcium Sulfide (CaS) is also valuable in chemical synthesis, where it often acts as a catalyst. In certain chemical reactions, CaS can speed up the process, making it essential for more efficient manufacturing. For example, CaS plays a role in sulfur-based reactions, where its stability and reactivity help produce desired compounds faster and with higher yields.

As a catalyst, CaS is known for its durability. It withstands extreme conditions without breaking down, which is important for industries that rely on consistent reaction rates. In applications like pharmaceuticals and specialty chemicals, CaS helps control the reaction environment, improving the overall quality and reliability of the final product.

For processes that demand stability and performance under pressure, CaS offers a dependable solution, helping industries save time and improve output.

3. CaS in Environmental Protection and Wastewater Treatment

Calcium Sulfide (CaS) plays a key role in environmental protection, especially in wastewater treatment. CaS helps remove harmful metals from water, making it safer for both people and the environment. When added to contaminated water, CaS reacts with heavy metals like lead, cadmium, and mercury, converting them into less harmful compounds that can be safely removed.

One major advantage of CaS in wastewater treatment is its efficiency. It can neutralize acidic pollutants and lower the overall toxicity of wastewater. This is critical for industries like mining and manufacturing, where wastewater often contains dangerous chemicals.

CaS is also cost-effective, which makes it a preferred choice in large-scale treatment facilities. By helping to clean water and reduce environmental impact, CaS supports safer and more sustainable industrial practices.

4. CaS in High-Temperature Ceramics and Glass Manufacturing

Calcium Sulfide (CaS) is useful in high-temperature applications, especially in the ceramics and glass industries. CaS has a high melting point, which allows it to remain stable at the extreme temperatures needed for manufacturing ceramics and specialty glass. This stability makes CaS ideal for use as an additive in materials that must withstand both heat and corrosive environments.

In glass production, CaS is often added as a clarifying agent. It helps remove impurities and improve the clarity of the final glass product. By using CaS, manufacturers can create high-quality glass with fewer defects, which is especially important for optical glass and display screens.

In ceramics, CaS contributes to the strength and durability of the final product. It ensures that ceramics used in high-stress environments, such as industrial equipment and protective coatings, can endure both heat and wear over time. With its thermal resistance and clarifying qualities, CaS remains a valuable material in both glass and ceramics manufacturing.

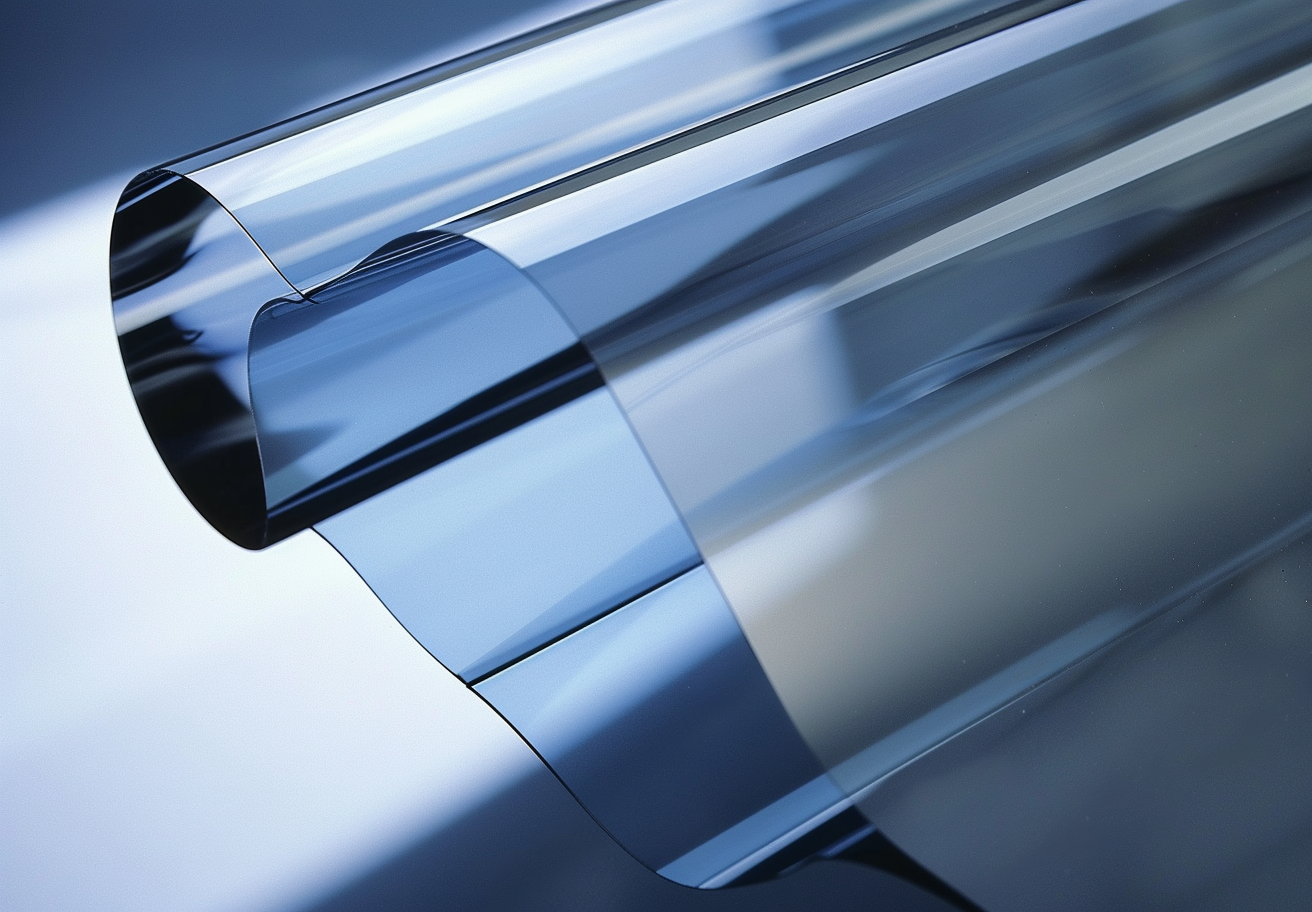

5. CaS in High-Tech Coatings

Calcium Sulfide (CaS) is increasingly used in high-tech coatings. Due to its stability and resistance to wear, CaS serves as a protective layer in industrial coatings. These coatings protect machinery and equipment from corrosion, heat, and other harsh conditions. CaS can withstand extreme environments, making it ideal for coatings in industries like aerospace, manufacturing, and automotive.

High-tech coatings that use CaS contribute to the durability of critical components, reducing maintenance costs and extending equipment life. This makes CaS a preferred material for manufacturers seeking reliable, long-lasting coatings.

Conclusion: The Future of CaS in Modern Industry

Calcium Sulfide (CaS) is a valuable material across industries, including photonics, chemical synthesis, environmental protection, high-temperature ceramics, and advanced coatings. Its stability, optical properties, and ability to withstand extreme conditions make it ideal for many demanding applications. As technology and industry standards evolve, the need for high-quality, reliable materials like CaS will only grow.

Companies like Stanford Advanced Materials (SAM) support these developments by providing CaS solutions tailored to these diverse applications. For those interested in CaS for sputtering, evaporation, or other uses, visit our Calcium Sulfide Sputtering Target and Calcium Sulfide Evaporation Materials pages for more details.