When we think about semiconductor manufacturing, we often picture highly advanced technologies, intricate processes, and an army of materials working in the background. Among these materials, tantalum (Ta) sputtering targets play a surprisingly crucial role. But why exactly is this unassuming metal so important for semiconductor devices? Let’s dive in.

What Makes Tantalum So Special for Semiconductors?

Tantalum, a refractory metal, is known for its excellent corrosion resistance, high melting point, and stable electrical properties. These characteristics make it a go-to choice for many high-performance applications. In semiconductor manufacturing, tantalum is commonly used as a target material in sputtering systems, where its unique properties help create thin films crucial to the functionality of modern electronics.

Tantalum Sputtering Targets

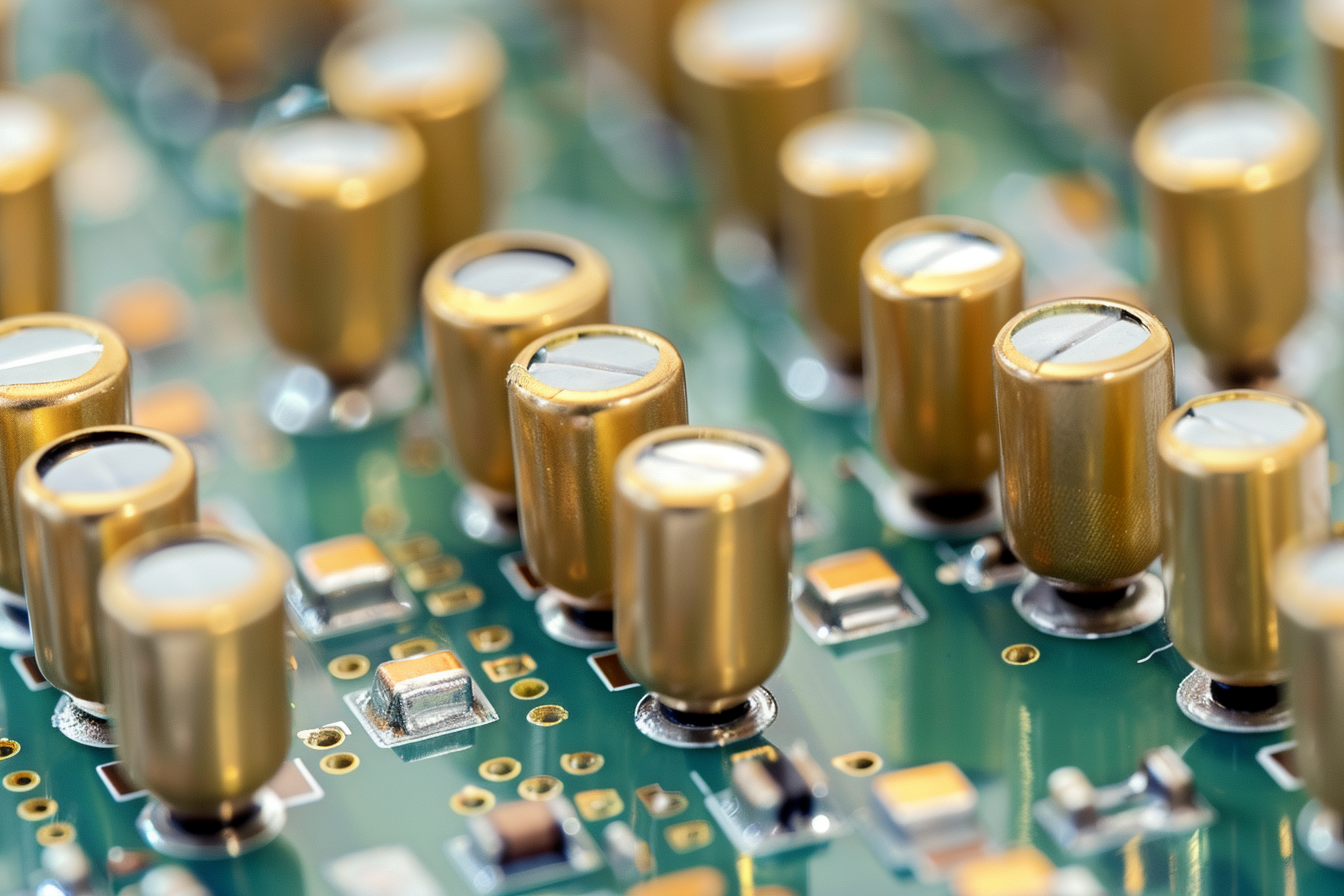

Sputtering is a process used to deposit thin films onto semiconductor wafers, creating layers that form the foundation of microchips and other electronic components. The target material—usually in the form of a disk or bar—is bombarded with high-energy particles, causing atoms from the target to eject and deposit onto the wafer.

Why choose tantalum for this process? Tantalum’s high atomic number, combined with its stability in high temperatures and vacuum conditions, ensures a consistent, high-quality deposition. Tantalum targets also enable precise control over film thickness, which is vital for the performance and reliability of the finished semiconductor device.

Tantalum’s Role in the Manufacturing Process

In semiconductor fabrication, films of tantalum are often used in applications like:

-

Gate Dielectrics: Tantalum is a key component in the production of gate dielectrics for CMOS (complementary metal-oxide-semiconductor) devices. These dielectrics help control the flow of current between different layers, ensuring that the device operates efficiently and reliably.

-

Capacitors: Tantalum oxide thin films are used in the manufacture of high-performance capacitors, which store and release electrical energy as needed in semiconductor devices. These capacitors are essential in everything from mobile phones to automotive electronics.

-

Interconnects: Tantalum is also used in the creation of interconnects between different layers of a semiconductor device. These connections allow for the transmission of electrical signals within the chip, enabling all the individual components to work in harmony.

The Advantages of Tantalum Targets

Tantalum’s role in semiconductor manufacturing goes beyond just being a reliable material. Here are a few reasons why it’s so highly regarded:

-

High Melting Point: With a melting point over 3,000°C, tantalum remains stable even in the harshest conditions of semiconductor processing. This stability helps ensure that sputtering targets maintain their integrity throughout the deposition process.

-

Superior Corrosion Resistance: Tantalum is highly resistant to corrosion, even in reactive environments. This makes it ideal for the vacuum chambers used in sputtering systems, where materials can be exposed to aggressive conditions.

-

Good Electrical Conductivity: Tantalum’s ability to conduct electricity is crucial for semiconductor applications, where precise control of electrical properties is necessary.

-

Precision in Thin Film Deposition: Tantalum allows for accurate, controlled deposition of thin films, which is essential for creating high-quality semiconductor devices. This precision ensures that each layer performs optimally, which is key for reducing device failure rates.

Sustainability and Cost-Effectiveness

Another reason tantalum targets are favored in semiconductor manufacturing is their sustainability. While tantalum is a rare metal, it is recyclable, which helps reduce the need for new mining and the associated environmental impacts. Additionally, tantalum sputtering targets are durable and have a long lifespan, making them a cost-effective choice for manufacturers in the long run.

Conclusion: Tantalum Targets in Semiconductor Manufacturing

Tantalum targets are indispensable in semiconductor manufacturing, thanks to their unique combination of physical properties. From gate dielectrics to interconnects, tantalum helps ensure that the devices we rely on every day perform at their best. As semiconductor technologies advance, tantalum will continue to be a key material, helping create the devices that power the next wave of innovation.

Need help selecting or sourcing tantalum sputtering target? At Stanford Advanced Materials, we provide custom and standard solutions tailored to your technical needs. Let’s find the right target for your next breakthrough.

Send An Inquiry