Introduction

Thin-film deposition techniques play a crucial role in various industries, providing protective coatings that enhance the properties of materials. Among these methods, Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) stand out, each distinguished by their unique characteristics, including the temperature at which they operate.

Temperature Difference in PVD

Definition and Basic Principles

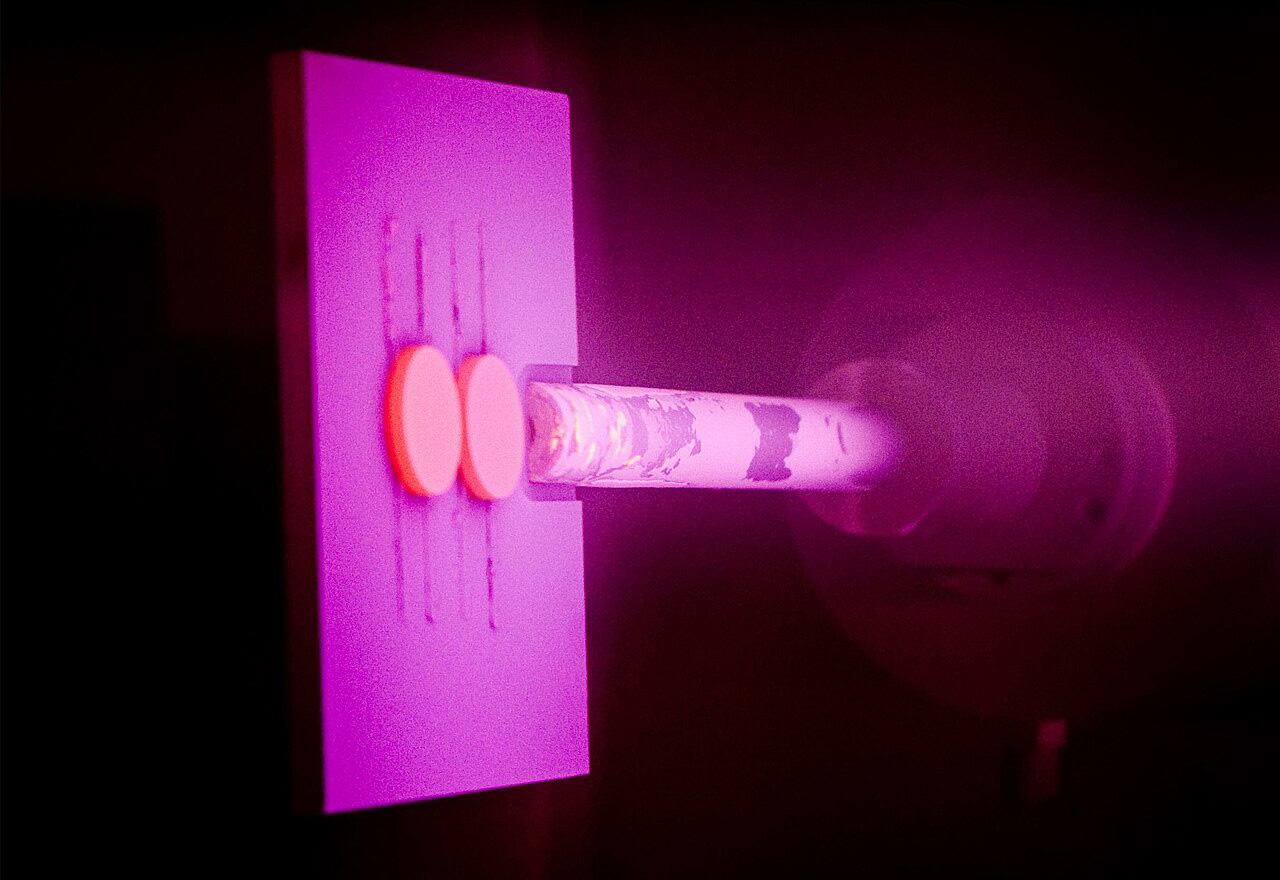

PVD encompasses evaporation and sputtering processes. In evaporation, materials transition from a solid to a vapor state, while sputtering involves ejecting particles from a target material.

Operating Temperatures

PVD operates at relatively low temperatures, a characteristic that offers advantages, particularly in preserving the integrity of temperature-sensitive materials. The processes involved in PVD make it suitable for a wide range of applications across various industries.

Applications

PVD finds widespread use in industries such as electronics, optics, and automotive. Materials like metals, alloys, and ceramics are commonly employed in PVD coatings, showcasing its versatility.

Temperature Difference in CVD

Definition and Basic Principles

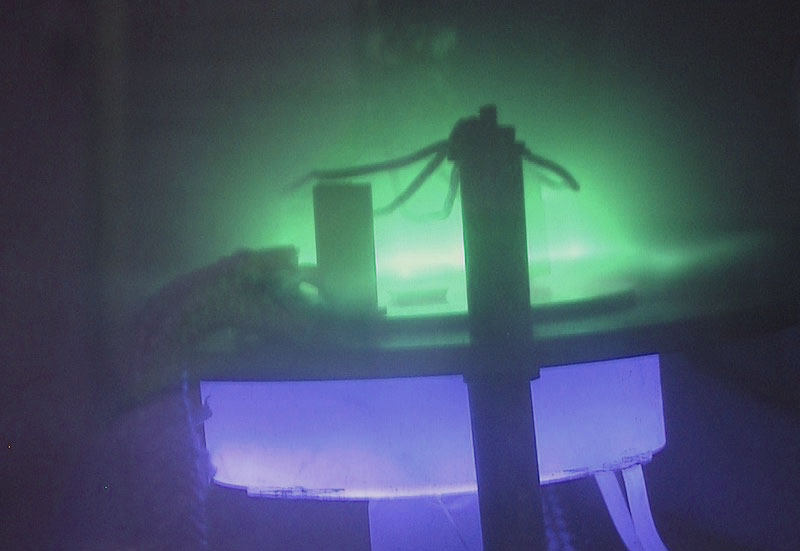

CVD, in contrast, relies on chemical reactions to deposit thin films onto substrates. These reactions occur between gaseous precursors, resulting in the formation of a solid film.

Operating Temperatures

CVD operates at significantly higher temperatures compared to PVD. The elevated temperatures are necessary for the chemical reactions to take place, presenting challenges, especially when coating materials onto tools made of high-speed steel.

Applications

CVD is widely used in semiconductor manufacturing, aerospace, and the production of advanced materials. The method allows for precise control over the composition and structure of the deposited films.

Comparison Between PVD and CVD

Temperature Differences

PVD’s relatively low operating temperatures provide a notable advantage, allowing the coating of temperature-sensitive materials. In contrast, CVD involves high temperatures, which can exceed the tempering temperature of high-speed steel, impacting the hardness of tools.

Material Compatibility

The temperature differences between PVD and CVD influence the choice of materials. PVD is suitable for a broader range of materials, including those sensitive to high temperatures. In contrast, CVD may require additional heat treatment, such as vacuum heat treatment, to restore the hardness of tools after coating.

Tool Coating Example

A specific example illustrates the necessity of vacuum heat treatment in CVD for tool coatings. Tools subjected to CVD processes may experience a loss of hardness, highlighting the importance of post-coating treatments to maintain performance.

Visualizing the Temperature Range

| Aspect | Physical Vapor Deposition (PVD) | Chemical Vapor Deposition (CVD) |

|---|---|---|

| Basic Principles | Evaporation, Sputtering | Chemical Reactions, Low-Temperature CVD |

| Operating Temperatures | Relatively Low | High |

| Advantages | Suitable for Temperature-Sensitive Materials | Precise Control over Film Composition |

| Common Industries | Electronics, Optics, Automotive | Semiconductor, Aerospace |

| Common Materials | Metals, Alloys, Ceramics | Advanced Materials |

| Tool Coating Considerations | Compatible with a Broad Range of Materials | High-Speed Steel Tools May Require Vacuum Heat Treatment |

| Example Application | Decorative Coatings, Hard Coatings | Semiconductor Device Manufacturing |

Note: The exact temperatures can fluctuate depending on the specific material undergoing deposition and the conditions of the deposition process.

Conclusion

In conclusion, the temperature dynamics in thin-film deposition play a critical role in choosing between PVD and CVD. Understanding the operating temperatures, material compatibility, and the impact on specific applications is vital for making informed decisions. As technology advances, ongoing developments in thin-film deposition techniques continue to shape the landscape of materials science and industrial applications. For more information about the difference between PVD and CVD, please refer to Table Comparison: Physical Vapor Deposition Vs. Chemical Vapor Deposition.