I. Introduction

Silicon-on-insulator (SOI) technology represents a pivotal advancement in semiconductor manufacturing, offering enhanced performance and efficiency over traditional bulk silicon approaches. By integrating a thin silicon layer atop an insulating substrate, SOI facilitates superior electrical isolation and reduced parasitic capacitance, which is critical for high-performance electronic devices.

SOI involves layering a silicon wafer on an insulating material, typically silicon dioxide. This structure mitigates unwanted electrical interactions between components, enhancing device speed and energy efficiency. The fundamental principle hinges on isolating the active silicon layer from the bulk substrate, providing a pristine environment for semiconductor device fabrication.

In the realm of electronics, SOI technology is instrumental in driving innovation across various applications, including microprocessors, RF circuits, and optoelectronics. Its ability to minimize power consumption and thermal issues makes it indispensable for modern high-performance and low-power devices.

This article delves into the core advantages of SOI technology, its intricate manufacturing processes, diverse applications and the challenges it faces. Each section provides a comprehensive understanding of SOI’s role in shaping the future of electronics.

II. Core Advantages of SOI Technology

Reduction of Junction Capacitance and Power Consumption

SOI structures significantly lower junction capacitance, which translates to reduced power consumption. This characteristic is crucial for extending the battery life of portable devices and enhancing the overall energy efficiency of electronic systems.

Enhanced Chip Performance

The isolation provided by the insulator layer allows for faster switching speeds and higher operational frequencies. As a result, SOI-based chips exhibit superior performance compared to their bulk silicon counterparts, making them ideal for high-speed computing and advanced communication systems.

Extended Device Battery Life

By minimizing power leakage and optimizing energy usage, SOI technology contributes to longer battery life in mobile and wearable devices. This extension is particularly beneficial in applications where energy efficiency is paramount.

Increased Operational Speed

SOI devices operate at higher speeds due to reduced parasitic effects and improved electrical isolation. This enhancement is vital for applications requiring rapid data processing and real-time responsiveness.

Performance Enhancements Over Traditional Bulk Silicon CMOS Chips

Compared to conventional CMOS chips, SOI technology offers up to a 15% increase in operational speed and a corresponding decrease in power consumption. The high-purity and uniformity of SOI substrates further amplify these performance benefits.

High Purity and Uniformity

SOI substrates boast exceptional purity and uniformity, essential for the reliable performance of RF and high-frequency devices. These qualities ensure consistent device behavior and longevity.

Importance for RF Devices

For Radio Frequency (RF) applications, SOI technology furnishes the essential isolation and high-frequency performance required to develop efficient RF amplifiers, transceivers, and filters. The superior purity and uniformity of SOI substrates minimize signal loss and enhance signal integrity, which are paramount in maintaining the fidelity of high-frequency transmissions. Consequently, SOI is instrumental in advancing telecommunications, wireless connectivity, and other RF-dependent technologies, ensuring robust and reliable performance in increasingly demanding applications.

III. Manufacturing Processes of SOI Technology

Seed Method

The seed method is a fundamental technique in SOI manufacturing, wherein a silicon layer is meticulously grown directly atop an insulating substrate. This process begins with the deposition of a thin silicon seed layer onto the insulator, followed by thermal oxidation to enhance the quality and uniformity of the silicon layer. Precise control over temperature and deposition rates ensures the formation of a defect-free silicon layer, which is crucial for the subsequent fabrication of high-performance semiconductor devices.

Diamond-Tipped Tool Method

The diamond-tipped tool method employs precision-engineered diamond instruments to etch and shape the silicon layer on the insulator. This technique offers superior control over the silicon layer’s thickness and surface topology, enabling the creation of intricate microstructures with minimal material wastage. The robustness of diamond-tipped tools ensures consistent and repeatable manufacturing processes, which are essential for maintaining the integrity and performance of SOI-based devices. Additionally, this method reduces processing time and enhances overall manufacturing efficiency.

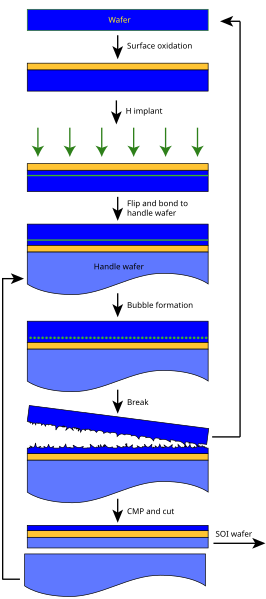

Smart Cut Process

The Smart Cut process represents an advanced fabrication technique that integrates layered oxidation with ion implantation to achieve exceptional control over the silicon-on-insulator structure. This method involves the creation of a thin silicon layer through a controlled exfoliation process, followed by ion implantation to introduce precise dopants into the substrate. Subsequent annealing steps facilitate the bonding of the silicon layer to the insulator, resulting in a high-quality SOI wafer. The Smart Cut process is celebrated for its ability to produce uniform and defect-free SOI substrates, making it indispensable for high-performance and scalable semiconductor manufacturing.

IV. Applications of SOI in Various Fields

Mixed-Signal and RF Applications

SOI technology is pivotal in mixed-signal and RF applications, where the integration of analog and digital functionalities on a single chip is essential. In cellular technology, SOI-based components enhance signal processing and power management, leading to more efficient and compact mobile devices. Consumer electronics benefit from reduced power consumption and increased processing speeds, while industrial applications leverage SOI’s robustness for reliable performance in demanding environments. The ability to integrate passive elements with active digital functions on SOI substrates facilitates the development of sophisticated and multifunctional electronic systems.

Cellular Technology

Within cellular technology, SOI technology enables the creation of high-efficiency RF transceivers and power amplifiers that are critical for seamless wireless communication. The reduced parasitic capacitance and improved thermal management inherent in SOI substrates contribute to better signal clarity and device longevity, which are essential for maintaining high-quality mobile networks and expanding wireless infrastructure.

Consumer Electronics

In the realm of consumer electronics, SOI technology underpins the development of faster, more energy-efficient microprocessors and memory devices. The enhanced performance characteristics of SOI-based components translate to improved functionality in smartphones, tablets, and wearable devices, offering users a superior experience through faster processing speeds and longer battery life.

Industrial Applications

Industrial applications of SOI technology encompass a wide range of uses, from automation and robotics to power management and sensor systems. The durability and reliability of SOI components ensure consistent performance in harsh industrial environments, while their high-speed capabilities facilitate real-time data processing and control.

RF Waveguides

SOI-based RF waveguides are integral to modern communication systems, providing efficient pathways for high-frequency signals. These waveguides support the transmission of large bandwidths with minimal loss, making them essential for applications such as 5G networks, satellite communications, and advanced radar systems. The ability to integrate multiple waveguide functionalities on a single SOI chip enhances the versatility and performance of RF communication infrastructure.

Multifunctional Integration and High-Frequency Antenna Construction

The multifunctional integration capabilities of SOI technology allow for the consolidation of various components, including antennas, amplifiers, and filters, onto a single chip. This integration is particularly beneficial in high-frequency antenna construction, where space and performance are critical. SOI-based antennas exhibit superior gain and bandwidth, enabling more efficient and compact wireless communication devices.

RF Amplifiers

SOI technology significantly enhances the performance of RF amplifiers by reducing signal distortion and increasing power efficiency. SOI-based RF amplifiers achieve higher gain and linearity, which are essential for maintaining signal integrity in high-frequency applications. The integration of SOI technology in RF amplifiers results in more efficient power usage and improved overall device performance.

RF Transceivers

RF transceivers fabricated using SOI technology offer exceptional performance characteristics, including low insertion loss and high linearity. These transceivers benefit from the inherent advantages of SOI, such as reduced parasitic capacitance and enhanced thermal management, which contribute to faster data transmission and improved energy efficiency. Applications in vehicle-to-vehicle communications and virtual reality systems particularly benefit from the superior performance of SOI-based RF transceivers.

RF Filters

SOI-based RF filters provide numerous advantages over traditional filter technologies, including smaller footprints, higher power handling capabilities, and extensive tuning ranges. These filters avoid the nonlinearities associated with varactor filters and the size constraints of switched filter banks, making them ideal for compact and high-performance RF systems. The programmability and low power consumption of SOI RF filters further enhance their applicability in modern communication devices.

V. Conclusion

Silicon-On-Insulator (SOI) technology stands as a cornerstone in the evolution of semiconductor devices, offering unparalleled advantages in performance, efficiency, and reliability. Its multifaceted applications across diverse industries—from automotive and consumer electronics to telecommunications and medical devices—underscore its pivotal role in driving technological innovation and meeting the ever-increasing demands of the modern world. As advancements in fabrication techniques and integration with emerging technologies continue to unfold, the prospects for SOI technology remain exceedingly promising, heralding a new era of high-performance and sustainable electronic solutions.

Stanford Advanced Materials excels in semiconductor SOI substrates, providing superior materials that enhance next-generation electronics. Through strategic partnerships and innovation, it supports diverse high-tech industries.

Send An Inquiry