Ever wondered what makes semiconductor devices work like magic? Well, the answer lies in the thin films that coat them, and one of these processes is the rotary metal target. These cylindrical, rotating forms of metal (like tantalum, niobium, and molybdenum) are used in sputtering, a key process in semiconductor manufacturing. If you’re involved in purchasing for semiconductor production, this article is for you. Let’s break down why these metals are crucial and how to choose the right one for your needs.

What’s the Deal with Rotary Metal Targets?

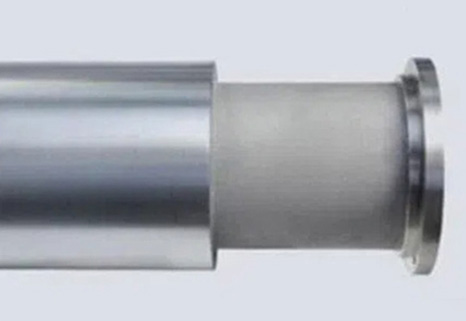

In a nutshell, rotary metal targets are circular metal forms used in sputtering—a process where ions bombard a target material, ejecting particles that then deposit onto a substrate, creating a thin, functional film. The catch? The target rotates to ensure uniform wear and deposition. Pretty cool, right?

Now, why are materials like tantalum (Ta), niobium (Nb), and molybdenum (Mo) so special for these tasks? Let’s dive into it.

Tantalum

When you think of durability, tantalum is probably top of mind. Why? This metal’s a powerhouse—perfect for high-performance devices that require top-tier electrical conductivity, corrosion resistance, and thermal stability.

So, why use tantalum in semiconductor sputtering?

-

Corrosion Resistance: Tantalum resists corrosion even in harsh environments. This makes it ideal for devices exposed to moisture and heat (think high-performance circuits).

-

High Melting Point: With a melting point over 3,000°C, tantalum won’t break a sweat in high-energy sputtering environments.

-

Great Electrical Conductivity: Essential for creating those thin films that make electronics work smoothly.

So, if you’re looking for a reliable, durable thin film, tantalum’s your guy.

Niobium

Niobium is a bit of a secret weapon in semiconductor sputtering. Why? Because it has superconducting properties and can withstand extreme temperatures—perfect for specialized applications like quantum computing.

What makes niobium stand out?

-

Superconductivity: Niobium is essential for devices where superconductivity matters. This is a must for next-gen tech like quantum computers.

-

Strength in Cold: It’s strong even at ultra-low temperatures, which is crucial for technologies used in cryogenic environments.

-

Excellent Bonding: Niobium forms strong bonds with other materials, helping to produce durable and reliable thin films.

So, if you’re working with cutting-edge quantum or cryogenic tech, niobium will be your go-to.

Molybdenum

Molybdenum is the Swiss army knife of metals—it’s versatile, reliable, and performs well in high-stress environments. Whether you’re dealing with high temperatures, electrical conductivity, or thermal stability, molybdenum is a safe bet.

Why choose molybdenum for sputtering?

-

Thermal Stability: It’s got amazing thermal conductivity, which is perfect for high-temperature semiconductor applications.

-

Electrical Conductivity: Molybdenum is great at conducting electricity, so it’s ideal for making thin films that need consistent electrical performance.

-

Wear Resistance: It’s built to last—molybdenum resists wear, so your rotary targets last longer, saving you costs in the long run.

Need a metal that’s reliable, tough, and doesn’t quit? Molybdenum’s got you covered.

How to Choose the Right Rotary Metal Target?

Choosing the right rotary metal target isn’t as simple as picking the first one you see. Here are a few things to keep in mind:

-

Material Composition: Is purity important? The composition of the target material affects film quality and performance.

-

Deposition Requirements: Are you after high deposition rates or super-thin films? Different targets work better for specific deposition needs.

-

Compatibility: Make sure your target material is compatible with the process gases (like argon or oxygen) and substrate materials (like silicon).

-

Temperature Tolerance: Check that the target can handle the temperatures expected during sputtering. You don’t want your target to degrade prematurely.

-

Cost vs. Performance: Yes, budget matters. But it’s essential to balance cost with performance. Sometimes, spending a little more up front can save you big-time down the road.

Conclusion

Tantalum, niobium, and molybdenum are the stars of the rotary metal target world, each bringing something unique to the sputtering table. Whether you need high durability, superconductivity, or thermal stability, these metals have got your back. When selecting a rotary metal target for semiconductor applications, keep in mind the key factors that can make or break your process, from material composition to temperature tolerance.

At Stanford Advanced Materials, we specialize in supplying high-quality rotary metal targets tailored for semiconductor sputtering. Have questions? Reach out to us! We’re here to help you make the right choice and ensure your thin-film deposition process runs smoothly and efficiently.