In the realm of material science and engineering, the pursuit of enhanced durability and longevity is a constant endeavor. The battle against wear and corrosion has led to the development of innovative techniques to fortify the surfaces of materials, and one such champion in this arena is Physical Vapor Deposition (PVD) technology. PVD coatings have emerged as a potent solution to combat wear and corrosion, finding applications across industries where the protection of surfaces is paramount.

Understanding Wear and Corrosion

Before delving into the prowess of PVD coatings, it’s crucial to understand the adversaries they are designed to counter: wear and corrosion. Wear occurs due to the gradual loss of material from a surface as a result of contact, friction, or abrasion. Whether it’s the erosion of machinery components or the degradation of cutting tools, wear can drastically affect the performance and lifespan of materials.

On the other hand, corrosion is the chemical deterioration of a material caused by reactions with its environment. Whether it’s the oxidation of metal structures or the deterioration of pipelines, corrosion possesses the capability to undermine material strength and jeopardize their structural soundness, ultimately resulting in safety risks and financial setbacks.

The Armor of PVD Coatings

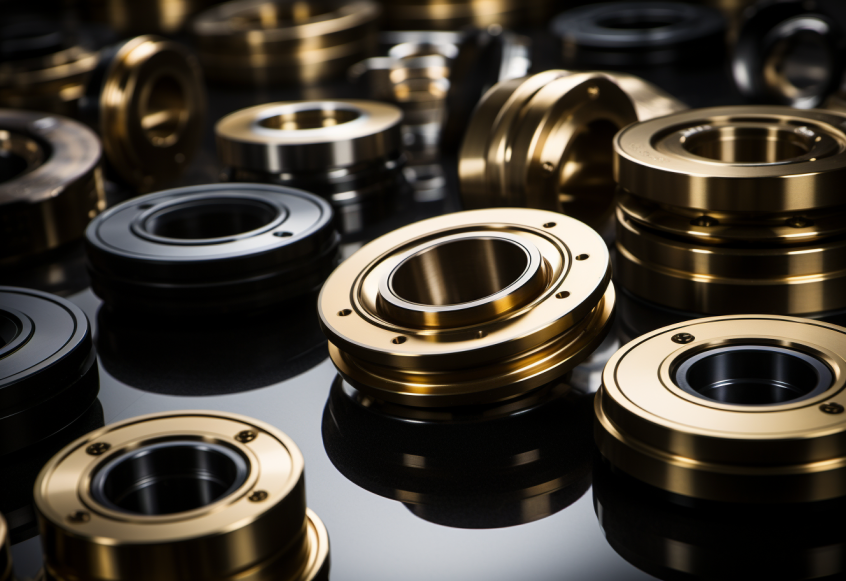

PVD technology presents an ingenious solution to the challenges posed by wear and corrosion. Through a meticulously controlled deposition process, thin layers of protective materials are applied to the surface of substrates, creating a robust barrier against the forces of nature and usage. The PVD process involves vaporizing a solid material into a vapor, which then condenses onto the substrate, forming a thin film.

One of the key advantages of PVD coatings is the ability to tailor the properties of the coating to suit specific applications. Various materials such as titanium nitride (TiN), chromium nitride (CrN), and diamond-like carbon (DLC) are used in PVD coatings to provide a combination of hardness, toughness, and resistance to wear and corrosion.

Applications Across Industries

The versatility of PVD coatings has led to their widespread adoption in industries where wear and corrosion resistance are essential. In the manufacturing sector, cutting tools coated with PVD materials exhibit extended tool life and improved cutting performance. This not only enhances productivity but also reduces the need for frequent tool replacements.

In the automotive industry, PVD coatings protect engine components from the harsh conditions within an engine bay, ensuring optimal performance and longevity. Similarly, the aerospace sector benefits from PVD-coated components that withstand the demanding conditions of flight, including temperature fluctuations and exposure to various chemicals.

A Glimpse into the Future

As technology continues to advance, so does the potential of PVD coatings. Researchers are exploring nanocomposite coatings that combine different materials at the nanoscale to achieve exceptional properties. Additionally, innovations in PVD techniques are leading to coatings that offer not only wear and corrosion resistance but also improved thermal and electrical conductivity, expanding their applications to new frontiers.

Conclusion

In the eternal quest for durability and reliability, PVD coatings have emerged as an indispensable tool. Their ability to provide an armor of wear and corrosion resistance on a variety of surfaces has revolutionized industries and paved the way for enhanced performance, reduced maintenance, and improved safety. As PVD technology continues to evolve, it’s certain that its influence on materials science and engineering will only grow stronger, securing a future where wear and corrosion become mere inconveniences of the past.

Stanford Advanced Materials (SAM) has rich experience in the physcial vapor deposition manufacturing aindustry. A variety of PVD coatings and raw materials are available on our website. Please visit our homepage for more information.