Introduction

Electrode coatings play a vital role in enhancing the performance and longevity of electrodes across various industrial applications. These coatings improve the electrode’s resistance to corrosion, wear, and other forms of degradation, thereby extending their service life and reducing maintenance costs. Precious metals, renowned for their excellent electrical and thermal conductivity, along with their resistance to oxidation and corrosion, are frequently used as coating materials for electrodes. This article explores the most commonly used precious metals for electrode coatings, offering insights into their features and applications.

Precious Metal Materials for Electrode Coatings

Precious metals are prized not only for their aesthetic appeal and economic value but also for their superior physical properties. Gold, silver, platinum, and other precious metals are extensively applied to electrodes due to their corrosion resistance, conductivity, and strength. However, the high cost of these metals often makes it impractical to use them in their pure form for electrode construction. Instead, applying precious metals as thin-film coatings on electrodes provides an economical alternative, preserving the desirable properties of these metals while optimizing cost efficiency.

Here are some of the most commonly used precious metals for electrode coatings:

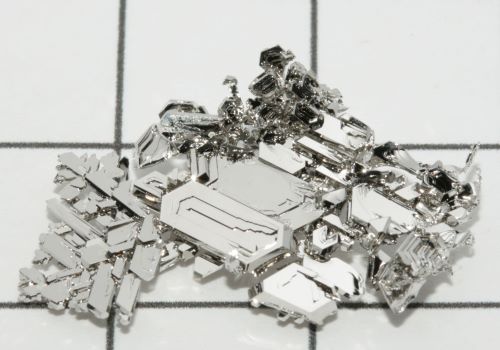

Gold

Gold is a widely used precious metal in electrode coatings due to its outstanding electrical and thermal conductivity. It is highly resistant to corrosion, making it unreactive to water, air, and oxygen.

Gold is a widely used precious metal in electrode coatings due to its outstanding electrical and thermal conductivity. It is highly resistant to corrosion, making it unreactive to water, air, and oxygen.

These properties make gold ideal for coating electrodes that require high levels of accuracy and precision, such as those used in medical devices and electronics.

Silver

Silver is a cost-effective alternative to other precious metals while offering impressive conductivity and corrosion resistance. It boasts the highest thermal and electrical conductivity among all metals. Additionally, its excellent resistance to oxidation and corrosion makes silver suitable for use in harsh environments.

Silver is a cost-effective alternative to other precious metals while offering impressive conductivity and corrosion resistance. It boasts the highest thermal and electrical conductivity among all metals. Additionally, its excellent resistance to oxidation and corrosion makes silver suitable for use in harsh environments.

Silver is commonly used as an electrode coating in applications such as electrical contacts, solar cells, and medical implants. However, silver should be avoided in humid environments as it may crack.

Platinum

Platinum is a highly durable and corrosion-resistant metal, making it an excellent choice for electrode coatings. Its exceptional electrical conductivity and catalytic activity enhance the performance of electrodes used in electrochemical reactions. Platinum’s stability at high temperatures and its resistance to most chemicals make it ideal for automotive and aerospace applications. Platinum is also widely used in electrode coatings for fuel cells, sensors, and electrochemical devices.

Platinum is a highly durable and corrosion-resistant metal, making it an excellent choice for electrode coatings. Its exceptional electrical conductivity and catalytic activity enhance the performance of electrodes used in electrochemical reactions. Platinum’s stability at high temperatures and its resistance to most chemicals make it ideal for automotive and aerospace applications. Platinum is also widely used in electrode coatings for fuel cells, sensors, and electrochemical devices.

Others

- Palladium: Palladium is a versatile and durable electrode coating material, commonly used in hydrogen sensors, fuel cells, and catalysis due to its excellent hydrogen absorption and release capabilities. Its ability to withstand harsh environments makes it a preferred choice for various industrial applications.

- Rhodium: Rhodium is another precious metal known for its exceptional hardness and resistance to corrosion. It is often used as a coating material for electrodes in high-temperature and corrosive environments, such as in catalytic converters and glass manufacturing. Rhodium’s reflective properties also make it useful in optical and reflective coatings, in addition to its application in electroplating.

- Ruthenium: Ruthenium is often employed in electrode coatings for applications such as supercapacitors, batteries, and electrocatalysis. Its high conductivity and catalytic activity significantly enhance the performance of electrodes in electrochemical reactions. Ruthenium is also noted for its durability in harsh chemical environments, which makes it ideal for use in chlor-alkali production and other electrochemical processes.

- Iridium: Iridium is one of the most corrosion-resistant metals, making it suitable for electrode coatings in extremely harsh environments. It is particularly valued in the production of electrodes for the chlor-alkali industry and in electrolytic cells used in hydrogen production. Iridium-coated electrodes are known for their long lifespan and low maintenance requirements.

- Rhenium: Rhenium is a rare and highly durable metal, often used in electrode coatings where extreme conditions are present, such as in rocket engines and high-temperature thermocouples. Its high melting point and resistance to wear make rhenium coatings ideal for applications requiring durability and stability under thermal stress.

Specific Applications of Precious Metals for MMO Electrode Coating

Precious metal coatings are extensively used in mixed metal oxide (MMO) electrodes, known for their high conductivity and corrosion resistance. These characteristics contribute to the stable performance and extended lifespan of MMO electrodes, which are widely used as anodes in electrolytic cells for chlorine production, printed circuit board manufacturing, and other industrial processes.

For example, in chlorine production, using MMO electrodes as anodes can reduce energy consumption. Precious metal coatings on these electrodes result in lower anode overpotential, which decreases cell voltage and power usage, leading to reduced energy costs and a more environmentally friendly manufacturing process.

Conclusion

Precious metals are highly valued for their exceptional electrical and thermal conductivity, corrosion resistance, and other advantageous properties. These qualities make them indispensable for electrode coatings in a wide range of industrial applications. Platinum, gold, silver, palladium, and ruthenium are among the most commonly used precious metals for these purposes.

Stanford Advanced Materials (SAM) has extensive experience in manufacturing and supplying precious metal coating materials at competitive prices. Contact us for more information or to request a quote.Key Materials for Electrode Coatings: Applications of Gold, Silver, Platinum, and Other Precious Metals

Reference:

[1] Platinum. (2023, April 10). In Wikipedia. https://en.wikipedia.org/wiki/Platinum

[2] Li Y, Li S, Zhang C, Xu N, Bao Z. Oxidation Behavior and Oxide Transformation of a Pt-Modified Aluminide Coating at Moderate High Temperature. Crystals. 2021; 11(8):972. https://doi.org/10.3390/cryst11080972