Introduction

The deposition rate is an important factor in the field of thin film deposition, as it directly affects the production efficiency and throughput of the process. In this article, we will discuss practical methods to increase the deposition rate for various deposition techniques. Hope that you can have a better understanding of the factors affecting deposition.

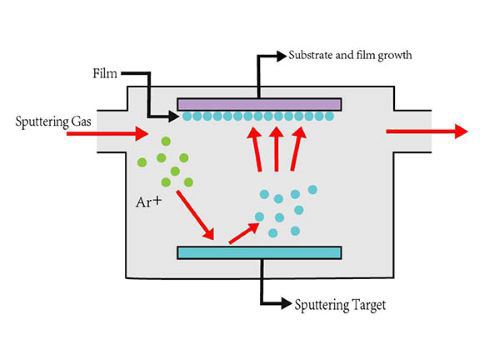

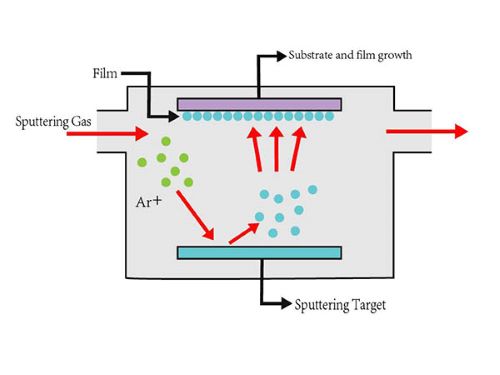

Figure 1. Sputtering Deposition

Practical Methods to Increase Deposition Rate

–Increasing the Deposition Source Power

The most common way to boost the deposition rate is to increase the power of the deposition source. This can be done by increasing the beam current, filament current, or RF power, depending on the type of deposition technique. With a greater source power, there are more atoms or molecules available for deposition, leading to a higher deposition rate.

Nevertheless, please be cautious when doing this, because high power might damage the system or melt the target. The power applied might dissipate, and there would be energy wasted and rising costs consequently.

–Decreasing the Source-to-substrate Distance

In some deposition techniques, the most effective method is to reduce the source-to-substrate distance (r). Since the sputtered particles’ arrival rate is a function of 1/r^2, decreasing the distance could largely increase the arrival rate and thus the deposition rate.

However, it is important to note that decreasing the r may also affect the uniformity and quality of the deposited film. The larger throw distance allows more particle collision, which selects refined particles and prepares more uniform films. While the reduced distance means less collision and less uniformity.

–Increasing the Substrate Temperature

You can also raise the substrate temperature to increase the deposition rate. When the substrate temperature is higher, the rate of diffusion of the deposited species on the substrate increases, resulting in a higher deposition rate.

Yet, please control the operating temperature within certain limits because raising the substrate temperature may also affect the properties of the deposited film, such as its crystal structure, composition, and adhesion.

–Using a Higher Pressure Environment

Changing the ambient pressure works as well. In some cases, increasing the pressure of the deposition environment can increase the deposition rate. This is particularly true for physical vapor deposition (PVD) techniques such as sputtering, where higher pressure can increase the density of the plasma, leading to a higher deposition rate.

The shift of pressure might lead to adverse effects. For one thing, increasing the pressure may also affect the characteristics of the deposited film, such as its density and surface roughness. For another, the uniformity of the thin film might be affected since there is less collision.

–Employing Multiple Sources

Using multiple deposition sources is another useful method. The deposition area can be increased with multiple sources, and various materials can be deposited simultaneously. This method is particularly helpful for co-deposition processes, where two or more materials are deposited together to form a composite film.

–Other Methods

Larger target sizes and more guns could also increase the deposition rate, although they are somewhat expensive. First, larger target sizes mean larger areas and higher sputter rates. Second, establishing one or more guns could double even triple the sputter rate and deposition rate.

Related reading: WHAT ARE SOME PRACTICAL WAYS TO INCREASE DEPOSITION RATES FOR A GIVEN TARGET MATERIAL AND SPUTTERING SYSTEM?

Conclusion

In a word, there are several practical methods to increase the deposition rate, including the change of power, distance, temperature, pressure, sources, and other elements. The most effective method depends on the specific deposition process and material being used. It is important to carefully consider the trade-offs between deposition rate and film properties before implementing any of these methods. Proper process control and optimization can lead to higher throughput and improved production efficiency in thin film deposition.

A variety of factors such as purity, density, porosity, grain sizes, temperature, and pressure should be controlled for higher deposition rates in the deposition process. Stanford Advanced Materials (SAM) is a leading supplier of sputtering targets of different sizes and shapes. We also provide technical advice if needed. Please visit our homepage for more information.