Introduction

Physical Vapor Deposition (PVD) coatings are essential in various industries, providing durability, aesthetics, and improved performance to numerous products. Among the materials used for PVD coatings, nickel, gold, and silver are prominent due to their unique properties and applications. This article delves into these metals’ benefits, applications, and characteristics in PVD coatings.

Introduction to PVD Coatings

Physical Vapor Deposition (PVD) is a vacuum coating process that produces thin films and coatings by vaporizing a solid material in a vacuum and depositing it on a substrate. PVD coatings are known for their hardness, durability, and resistance to wear, corrosion, and oxidation. This technology is widely used in various industries, including electronics, automotive, aerospace, and decorative applications.

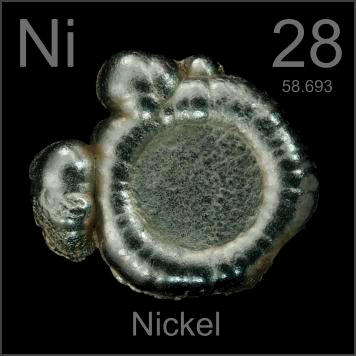

Nickel in PVD Coatings

Properties of Nickel

Nickel is a lustrous, silvery-white metal with excellent corrosion resistance, a high melting point, and good mechanical properties. It is highly ductile and can be easily polished, making it suitable for various coating applications.

Applications of Nickel Coatings

- Electronics: Used for connectors, contacts, and other components due to its excellent conductivity and corrosion resistance.

- Aerospace: Applied to engine components and turbines for enhanced durability and heat resistance.

- Automotive: Used for decorative finishes and protective coatings on various parts.

- Industrial Tools: Provides a hard, wear-resistant surface on cutting and drilling tools.

Benefits of Using Nickel

- High corrosion resistance

- Excellent mechanical properties

- Good adhesion to various substrates

- Enhanced durability and wear resistance

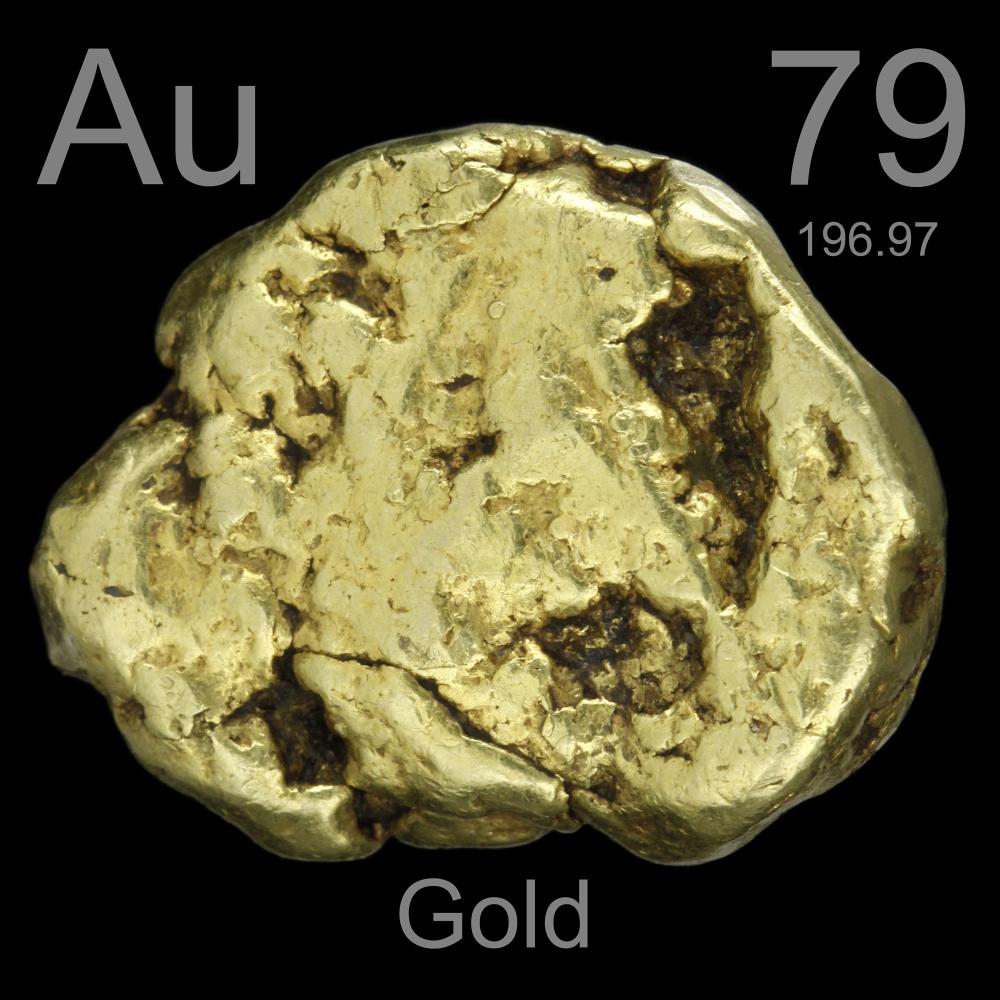

Gold in PVD Coatings

Properties of Gold

Gold is a highly valued, yellow metal known for its excellent conductivity, corrosion resistance, and biocompatibility. It has a relatively low melting point compared to other metals, making it easier to work with in PVD processes.

Applications of Gold Coatings

- Electronics: Essential for high-reliability connectors, switches, and printed circuit boards due to its conductivity and resistance to tarnish.

- Medical Devices: Used for implants and surgical instruments because of its biocompatibility and resistance to bodily fluids.

- Luxury Goods: Applied to jewelry, watches, and other high-end products for aesthetic appeal and durability.

- Optics: Utilized in coatings for lenses and mirrors to enhance reflectivity and durability.

Benefits of Using Gold

- Superior corrosion resistance

- Excellent electrical conductivity

- Biocompatibility

- Aesthetic appeal and luxury finish

Silver in PVD Coatings

Properties of Silver

Silver is a white, lustrous metal with all metals’ highest electrical and thermal conductivity. It is also highly reflective and has good antimicrobial properties.

Applications of Silver Coatings

- Electronics: Used in conductors, contacts, and soldering applications due to its exceptional conductivity.

- Medical Devices: Applied to wound dressings, catheters, and other medical tools for its antimicrobial properties.

- Optics: Utilized in mirrors, telescopes, and other optical devices for its high reflectivity.

- Decorative: Employed in jewelry, cutlery, and other decorative items for its aesthetic qualities.

Benefits of Using Silver

- Highest electrical and thermal conductivity

- Excellent reflectivity

- Antimicrobial properties

- Aesthetic appeal

Comparison of Nickel, Gold, and Silver PVD Coatings

| Property | Nickel | Gold | Silver |

|---|---|---|---|

| Corrosion Resistance | High | Superior | Moderate |

| Electrical Conductivity | Good | Excellent | Superior |

| Thermal Conductivity | Good | Good | Superior |

| Reflectivity | Moderate | High | Highest |

| Cost | Moderate | High | Moderate |

| Applications | Industrial, Decorative | Electronics, Medical | Electronics, Medical |

Conclusion

Nickel, gold, and silver each offer unique advantages for PVD coatings, making them suitable for different applications. Nickel is ideal for industrial uses due to its durability and corrosion resistance. Gold is preferred in electronics and medical devices for its conductivity and biocompatibility, while silver is valued for its superior conductivity and antimicrobial properties. Understanding the specific properties and benefits of each metal can help in selecting the appropriate PVD coating for various applications, ensuring enhanced performance and longevity.