Introduction

Evaporation is a typical process used in many laboratory applications such as thin film deposition, vacuum metallurgy, and semiconductor manufacturing. During evaporation, a material is heated until it evaporates and condenses onto a substrate. The choice of crucible and metal liners for this process is crucial to ensure optimal performance and yield. In this article, we will discuss the different crucibles and metal liners employed for evaporation.

Common Crucibles Used for Evaporation

Crucibles are essential components employed in laboratories as containers to hold samples during high-temperature processes for analysis, purification, etc. They are made of a range of materials and come in different shapes and sizes. Here are some commonly used crucibles for evaporation.

Copper Crucibles

These crucibles are durable and can withstand high temperatures. They are commonly used for metal evaporation. Additionally, copper crucibles have good thermal conductivity and are resistant to corrosion.

Platinum Crucibles

Platinum crucibles, made from precious metals, are also applied to metal evaporation. These crucibles are highly resistant to corrosion and high temperature, which makes them useful for the evaporation of other precious metals. SAM offers Standard Platinum Crucibles, as well as Volatile Matter Platinum Crucible, Phoenix Platinum Crucibles & Molds, etc.

Tungsten Crucibles

Tungsten crucibles, with a melting point of 3,422°C, are able to bear extremely high temperatures.

Quartz Crucibles

Quartz crucibles are employed for the evaporation of highly reactive materials such as silicon, germanium, and some metals. Such crucibles are highly transparent, allowing for easy observation of the evaporation process.

Graphite Crucibles

Graphite crucibles are ideal containers for the evaporation of non-metallic materials such as carbon and diamond. They are also highly resistant to thermal shock and can withstand high temperatures without melting.

Related reading: Good Experimental and Industrial Crucible Materials

Metal Liners Utilized for Evaporation

Crucible liners are another significant part of the evaporation process. They are thin layers of material placed inside the crucible to protect it from contamination or degradation during evaporation. For one thing, you can find aluminum liners, copper liners, platinum liners, and molybdenum liners widely used for the coating process. For another, there are many more metal liners suitable for different materials, such as nickel liners and stainless steel liners.

Nickel Liners

Nickel liners are applied to the evaporation of iron. These highly durable liners can withstand high temperatures up to 1,000°C.

Stainless Steel Liners

Stainless steel liners are employed for the evaporation of non-reactive metals and alloys such as aluminum, and copper alloys. These liners are highly durable and resistant to corrosion.

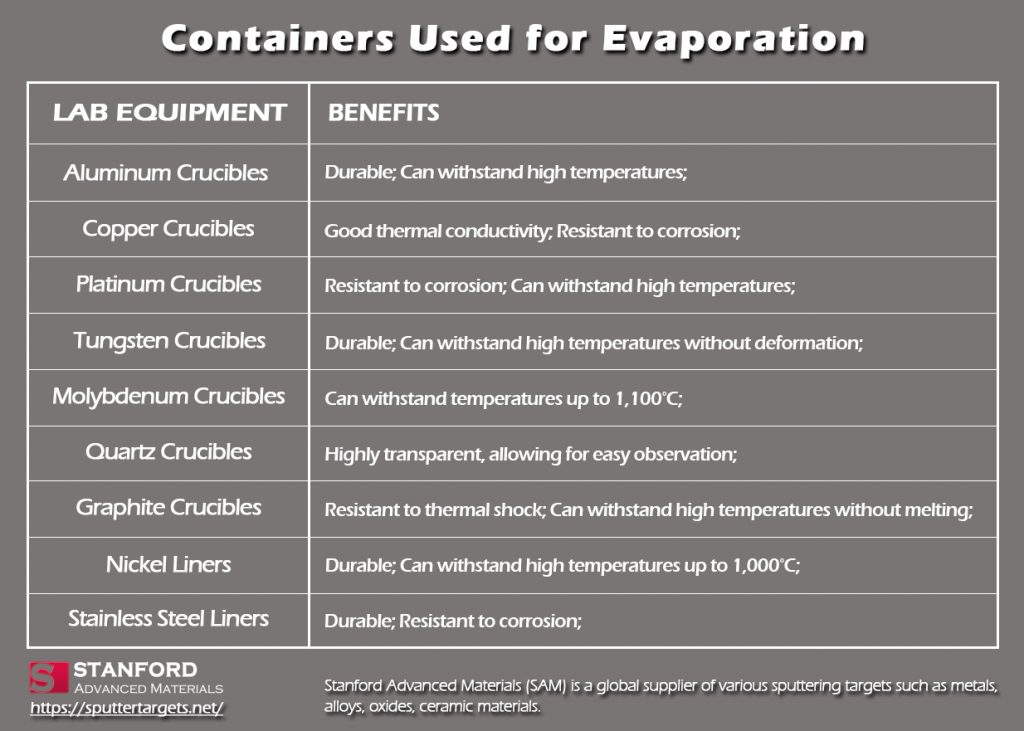

For more details, you can check the table below.

Conclusion

The choice of crucible and metal liner for evaporation depends on the material being evaporated and the specific requirements of the process. Aluminum, copper, platinum, tungsten, quartz, graphite, and molybdenum crucibles, as well as nickel liners, and stainless steel liners, are extensively used as containers for the evaporation of different materials. It is important to choose the correct apparatus to ensure optimal performance and yield during evaporation. By carefully selecting the right crucible and metal liner, you can achieve accurate and reliable results in your evaporation process.

Stanford Advanced Materials (SAM) is a leading supplier of crucibles and crucible liners. Other lab equipment and advanced materials are also available at a reasonable price. Send us an inquiry if you are interested.