Transparent conductive oxides (TCOs) are materials that possess the unique combination of being both electrically conductive and optically transparent. These materials are critical in a variety of modern technologies, including displays, solar cells, and touch screens. Among the most widely used TCOs are Indium Tin Oxide (ITO) and Fluorine-doped Tin Oxide (FTO). This article explores the properties, applications, and comparative advantages of ITO and FTO films as TCOs.

Understanding Transparent Conductive Oxides

What are TCOs?

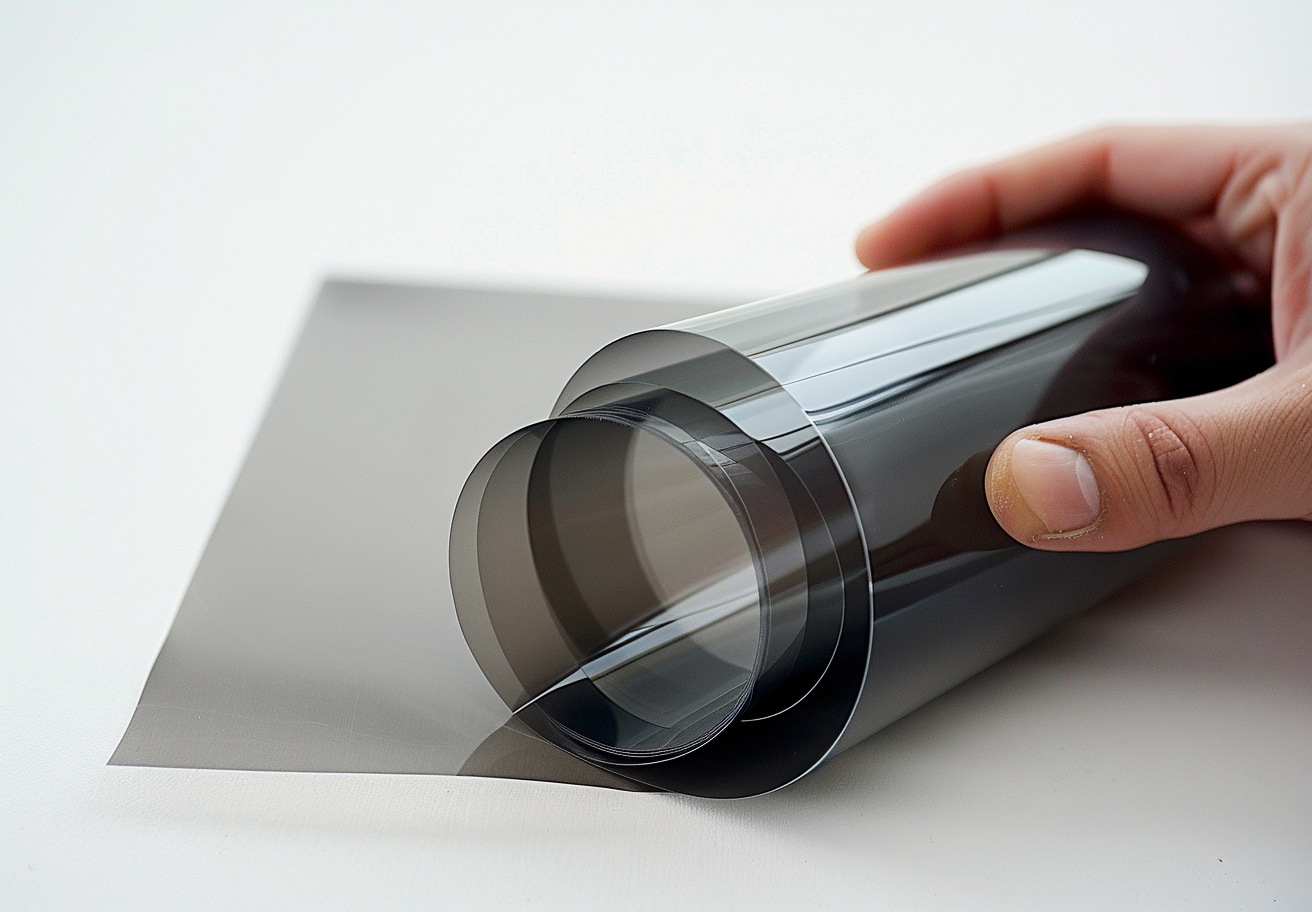

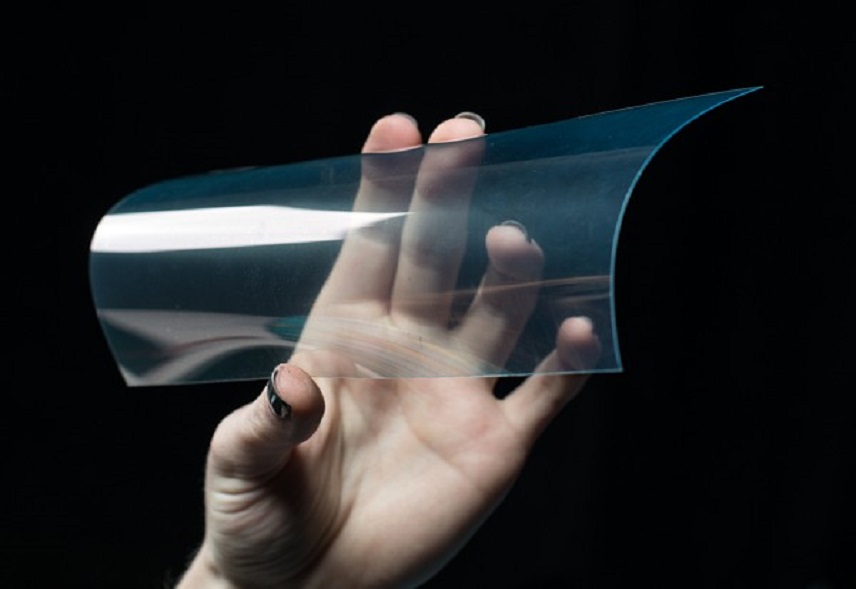

Transparent conductive oxides are thin film materials that allow light to pass through while also conducting electricity. This dual functionality makes them indispensable in devices where both optical clarity and electrical conductivity are required. TCOs are typically composed of metal oxides that have been doped with other elements to enhance their electrical properties without significantly reducing their transparency.

Importance of TCOs

The importance of TCOs in modern technology cannot be overstated. They are fundamental components in:

- Display Technology: Used in LCD, OLED, and touch screen displays to provide transparent electrodes that help generate and manipulate the images seen on the screen.

- Solar Cells: Serving as transparent electrodes that allow sunlight to enter and convert it into electrical energy while conducting the generated current.

- Smart Windows: Regulating light transmission and heat to improve energy efficiency in buildings by controlling the amount of light and heat passing through the windows.

Indium Tin Oxide (ITO)

Properties and Applications of ITO

Indium Tin Oxide (ITO) is a solution of indium oxide (In2O3) and tin oxide (SnO2), typically in a ratio of 90:10 by weight. The combination of these materials provides ITO with several key properties:

- High Optical Transparency: ITO films exhibit high transparency in the visible spectrum, making them ideal for display technologies.

- Electrical Conductivity: ITO is known for its excellent electrical conductivity, essential for efficient electronic devices.

- Smooth Surface: The surface of ITO films is typically very smooth, which is beneficial for applications requiring fine patterning and high-resolution displays.

- Workability: ITO can be deposited onto substrates using various methods, including sputtering and electron beam evaporation, allowing flexibility in manufacturing.

Due to its superior properties, ITO is widely used in various applications:

- Displays: ITO is the material of choice for the electrodes in LCDs, OLEDs, and touch screens, where its transparency and conductivity are crucial.

- Solar Cells: In photovoltaic cells, ITO acts as a transparent electrode that allows light to enter while also conducting the generated electrical current.

- Smart Windows: ITO films are used in smart windows that can change their transparency in response to an electrical signal, helping to regulate indoor lighting and temperature.

Fluorine-doped Tin Oxide (FTO)

Properties and Applications of FTO

FTO is composed of tin oxide (SnO2) doped with fluorine. The addition of fluorine atoms to the tin oxide lattice enhances its electrical properties:

- Good Optical Transparency: FTO films are highly transparent, though slightly less so than ITO, which makes them suitable for many optical applications.

- Electrical Conductivity: While the conductivity of FTO is generally lower than that of ITO, it is still adequate for many applications.

- Thermal Stability: FTO films are known for their excellent thermal stability, making them suitable for high-temperature applications.

- Chemical Resistance: FTO is more chemically stable than ITO, particularly in acidic or alkaline environments, which broadens its application range.

FTO films are used in a variety of applications, especially where environmental stability is a concern:

- Solar Cells: FTO is used as a transparent electrode in certain types of solar cells, including dye-sensitized solar cells (DSSCs), where its stability is advantageous.

- Heated Windows: Due to its thermal stability, FTO is used in heated windows that prevent fogging by conducting electricity to generate heat.

- Gas Sensors: FTO’s chemical resistance and conductivity make it suitable for use in gas sensors, where it can operate reliably in harsh environments.

Comparative Analysis: ITO vs. FTO

Electrical Conductivity and Optical Transparency

- ITO: ITO generally has higher electrical conductivity and greater optical transparency than FTO, making it more suitable for applications requiring high performance in these areas, such as advanced displays and high-efficiency solar cells.

- FTO: While FTO’s conductivity is lower, it is still adequate for many applications. Its slightly lower transparency is often acceptable, particularly in applications where durability and stability are more critical.

Thermal and Chemical Stability

- ITO: ITO is less thermally and chemically stable compared to FTO. It can degrade under high temperatures or in harsh chemical environments, which limits its use in certain applications.

- FTO: FTO excels in thermal and chemical stability. It can withstand higher temperatures and more aggressive chemical environments, making it suitable for applications where these conditions are encountered.

Cost and Availability

- ITO: Indium is a relatively rare and expensive element, which makes ITO films more costly. The cost can be a significant factor in large-scale applications or cost-sensitive products.

- FTO: Tin and fluorine are more abundant and less expensive than indium. Consequently, FTO films are generally more cost-effective, providing a viable alternative to ITO in many applications.

Environmental Impact

- ITO: The scarcity and mining process of indium raise environmental and sustainability concerns. Recycling of ITO films is possible but not always economically feasible.

- FTO: FTO’s raw materials are more abundant and less environmentally impactful, making it a more sustainable choice from a material sourcing perspective.

Conclusion

Indium Tin Oxide (ITO) and Fluorine-doped Tin Oxide (FTO) are two most prominent transparent conductive oxides used today. Each material offers unique advantages and is suited to different applications depending on the specific requirements for electrical conductivity, optical transparency, thermal stability, and cost. ITO remains the preferred choice for high-performance applications requiring the highest levels of transparency and conductivity. In contrast, FTO provides a cost-effective and durable alternative for applications where stability and environmental resistance are paramount.

One of the key aspects of ITO’s application is the use of ITO sputtering targets, which are crucial for the film deposition process in manufacturing high-quality ITO films. These targets ensure the uniformity and performance of the ITO layer, which is essential for the efficiency and reliability of the end products.

Stanford Advanced Materials (SAM) is a leading supplier of these vital materials, including both ITO and FTO products. SAM’s expertise in providing high-quality TCO materials supports the technological advancements and the demand for high-performance, sustainable materials. With the help of suppliers like SAM, industries can continue to develop and innovate, ensuring that both ITO and FTO remain at the forefront of modern technology.