Introduction

ITO (Indium Tin Oxide) is a key material used in displays, touchscreens, and solar panels. It is essential for modern technology. However, working with ITO comes with risks, especially during deposition and cleaning. Dust exposure can harm workers’ health if not managed properly.

This article explains where ITO dust exposure might happen and how to stay safe. It includes practical solutions to protect yourself and your team from potential hazards.

What is ITO, and Why Does Dust Exposure Matter?

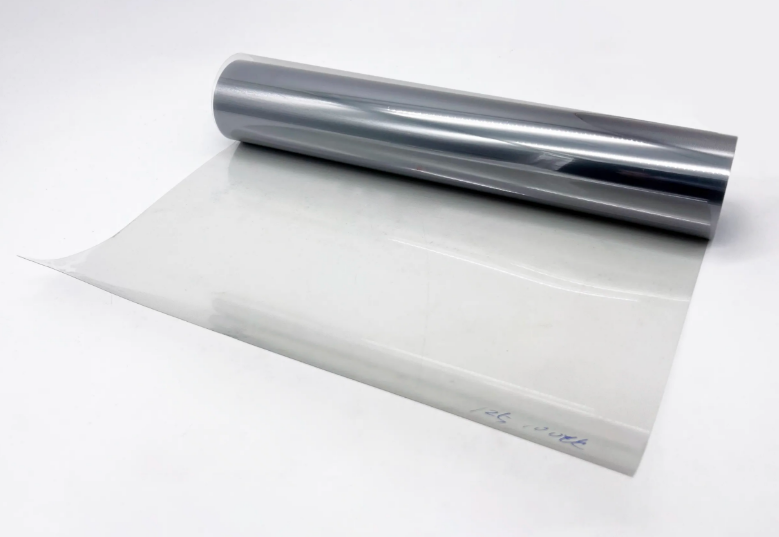

Indium Tin Oxide is a transparent conductive material made from indium, tin, and oxygen. It is widely used in electronic displays, touchscreens, and antistatic coatings. ITO films are typically created using sputtering or evaporation processes in vacuum chambers, where materials like ITO sputtering targets and ITO evaporation materials play a key role.

While ITO is critical for technology, exposure to its dust can be harmful. Inhaled ITO particles can cause serious lung conditions, such as interstitial lung disease. NIOSH recommends keeping respirable indium concentrations below 0.1 mg/m³ to minimize health risks.

In normal deposition processes, ITO is in a gaseous or ionized form, so direct exposure is low. However, risks arise during certain operations, such as opening chambers or cleaning deposited materials.

Where Does ITO Dust Exposure Happen?

Dust exposure can occur in specific scenarios:

- When opening the chamber:

Particles that have not settled can be released into the air. - During cleaning or maintenance:

Deposits on surfaces like shielding or walls may become airborne when disturbed.

These actions may seem routine, but over time, exposure to these particles can accumulate and pose health risks.

How to Minimize ITO Dust Exposure?

To reduce the risks of ITO dust exposure, you can take several practical steps:

1. Improve handling procedures:

Allow the chamber to sit idle for a few minutes before opening. This lets unsettled particles settle on surfaces, reducing airborne exposure. If possible, use local exhaust ventilation near the chamber opening to capture any particles released during operation.

2. Use personal protective equipment (PPE):

Workers should wear N95 masks or higher-rated respirators to protect against inhaling fine particles. Eye protection, gloves, and dust-proof clothing are also essential when working inside the chamber. Avoid wearing contaminated clothing outside the work area.

3. Monitor the air regularly:

Routine air monitoring helps ensure that respirable indium levels stay within safe limits. NIOSH recommends a maximum of 0.1 mg/m³ for an 8-hour workday. If concentrations exceed this limit, additional controls like improving ventilation or adjusting workflows may be necessary.

4. Keep the workspace clean and organized:

Avoid eating or drinking in areas where ITO is handled. Make sure tools and surfaces are cleaned regularly to prevent dust buildup.

These steps can significantly reduce exposure risks and protect workers’ health. Implementing them consistently is key to creating a safer work environment.

Why Should the Industry Focus on Managing ITO Dust Exposure?

ITO dust exposure is not just an individual health concern—it’s a broader industry issue. Proper dust management is critical for several reasons:

- Health and Safety Standards:

Chronic exposure to indium-containing particles can lead to severe health conditions like interstitial lung disease. Ensuring worker safety aligns with global occupational health standards, such as those outlined by NIOSH. - Workplace Productivity:

A safe and healthy work environment reduces absenteeism and fosters better morale among employees. Workers are more productive when they feel protected and valued. - Regulatory Compliance:

Industries handling hazardous materials must meet legal and regulatory requirements. Proactive dust control can help companies avoid penalties and maintain their reputation. - Innovation and Responsibility:

Addressing ITO dust exposure challenges pushes the industry to innovate better safety solutions. It also demonstrates social responsibility, showing that worker health is a priority.

By focusing on ITO dust exposure management, companies can set a benchmark for safety and sustainability while protecting their workforce.

Conclusion

ITO is an essential material for many industries, but working with it requires attention to safety. Dust exposure during handling, cleaning, or maintenance can pose serious health risks if not properly managed. By implementing simple measures like allowing settling time, wearing protective equipment, and monitoring air quality, you can create a safer work environment.

This article was inspired by a question we received about ITO dust exposure. At Stanford Advanced Materials (SAM), we prioritize providing high-quality materials while raising awareness about safe handling practices. By focusing on safety, you can protect both your team and the quality of your projects.