Introduction

Garnets (A3B2(SiO4)3) are a group of minerals commonly used as substrates, abrasives, and gemstones. Garnets share similar physical properties and crystal structures, yet they have disparities in chemical composition. Here, this article is going to explore the garnet family in the specific case of gadolinium gallium garnet. Hope that you can have a basic understanding of the features, production methods, and applications of gadolinium gallium garnet.

What Is Gadolinium Gallium Garnet?

Gadolinium gallium garnet (Gd3Ga5O12) is a synthesis garnet with impressive thermal, mechanical, and optical properties.

- Gadolinium gallium garnet (GGG) has a high thermal conductivity of 7.4W m-1K-1 and a high melting point of about 1730℃.

- It also stands out with a Mohs hardness of 6.5 to 7.5.

- As for optical features, GGG has an optical loss that is lower than 0.1%/cm. It is transparent enough for optical components between 0.36 and 6.0 μm, while the refractive index of GGG ranges from 2.0 at the UV end to 1.8 at the IR end of the spectrum.

How to Produce Gadolinium Gallium Garnet?

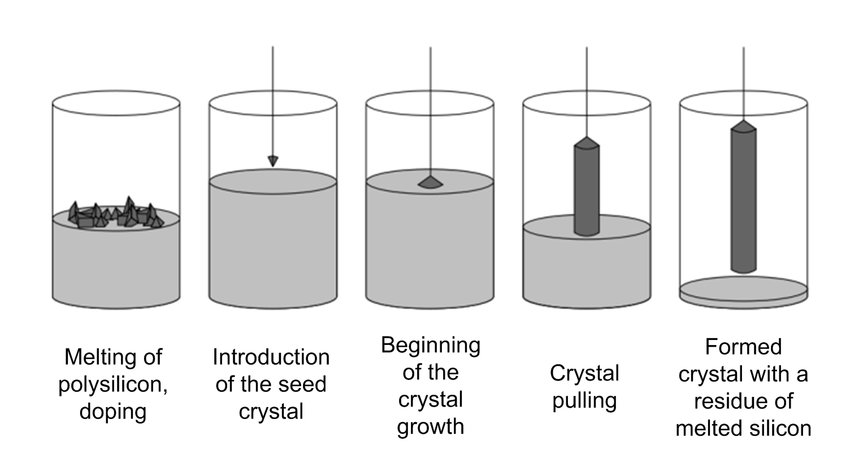

Czochralski process is employed to manufacture gadolinium gallium garnet and other types of single crystals. Initially, Polish scientist Jan Czochralski created this method by accident. He dipped his pen in a molten tin instead of his inkwell, and a tin mono-crystal came into being. The Czochralski process got its name this way, and such a technique was developed and became the prime method to make crystals. Figure 2. is the schematic diagram of the Czochralski process for making silicon crystal.

The Czochralski process can be divided into the following steps.

- First, put the material into a round crucible and heat them to get molten metals.

- Second, dip a seed crystal into the molten material and rotate it slowly.

- Next, withdraw the seed crystal carefully. You can obtain a lot of crystallized melt at the interface of the seed.

Besides, make sure such a process is carried out in an inert atmosphere to avoid contamination and oxidation. Please keep the heating power, the rotation rate, and the pulling rate well-controlled to get a suitable crystal shape. You can also add various dopants to change the garnet’s color, which is commonly used with semiconductor materials, such as silicon and gallium arsenide.

Applications of Gadolinium Gallium Garnet

Because of their desirable features, gadolinium gallium garnet found lots of applications in a range of industries.

GGG is applied as the substrate material for magneto-optical films. For instance, you can make infrared optical isolators using yttrium iron garnet (YIG) film on the gadolinium gallium garnet substrate. It is also used as a substrate material for magnetic bubble memory since their lattice parameter matches closely. You can find GGG crystal as an essential substrate for microwave isolators as well.

It was used as a diamond simulant in the 1970s. Thereafter, GGG was quickly replaced by yttrium aluminum garnet (YAG) because YAG has higher hardness. However, GGG has a much closer appearance to natural diamonds.

Other Garnet Materials

There are many more synthesis garnets on our website.

You can select cerium-doped gadolinium aluminum gallium garnet (Ce: GAGG) for its high light yield, fast scintillation response, chemical stability, and good energy resolution. It is a good choice for X-ray imaging, computed tomography (CT), and other medical imaging techniques.

Neodymium-doped yttrium aluminum garnet (Nd: YAG) is also available. It possesses great optical absorption and conversion efficiency, and this material is widely used in laser marking machines, beauty instruments, and cutting machines.

Please visit our homepage for more information.

Related reading: An Introduction to 7 Types of Synthetic Garnet Materials

Conclusion

Thanks to its high melting point, high thermal conductivity, great hardness, and good optical features, gadolinium gallium garnet (GGG) is extensively used as a substrate and gemstone. Stanford Advanced Materials (SAM) offers high-purity garnets of various diameters. Send us an inquiry if you are interested.