Introduction

Transparent Conductive Oxides (TCOs) are pivotal materials in the field of modern technology, bridging the gap between optical transparency and electrical conductivity. Among these, Aluminum-doped Zinc Oxide (AZO) stands out as a particularly efficient TCO, offering a combination of transparency, conductivity, and affordability that is crucial for a variety of applications ranging from solar cells to touch panels.

AZO comprises zinc oxide (ZnO) doped with aluminum to enhance its electrical properties without significantly compromising its optical transparency. This unique balance makes it an ideal candidate for applications where both high transparency and conductivity are required. The purpose of this article is to delve into the properties, applications, and technological advances of AZO, providing a comprehensive overview of its role and potential in advancing transparent conductive technologies.

This exploration not only highlights AZO’s fundamental characteristics and benefits over other TCOs but also examines its key applications and recent technological advancements in deposition and patterning techniques. Through this discussion, we aim to provide insights into how AZO continues to shape various technological landscapes and speculate on its future developments and challenges in the field.

Understanding AZO

Chemical Composition and Basic Properties

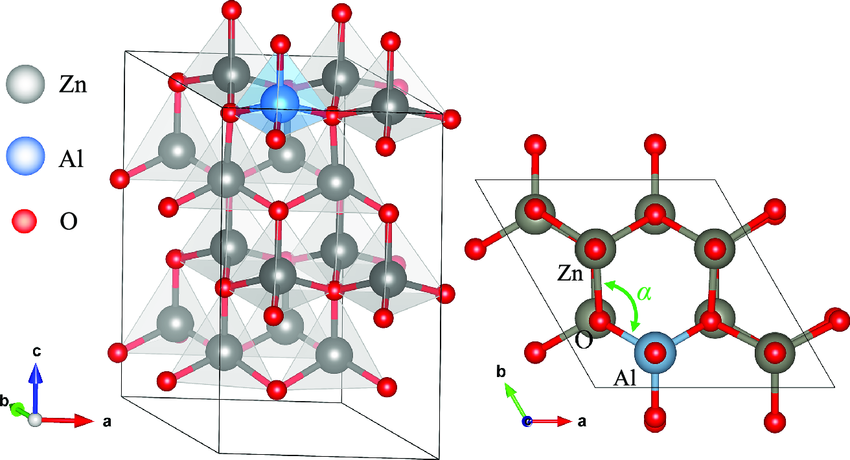

Aluminum-doped Zinc Oxide (AZO) is composed of zinc oxide where a fraction of zinc ions is replaced by aluminum ions, typically at concentrations varying from 1 to 5 percent. This doping significantly enhances the electrical properties of zinc oxide while maintaining its optical transparency within the visible spectrum.

Optical Properties

AZO is renowned for its high transparency in the visible spectrum, making it an excellent choice for applications requiring minimal light obstruction. Additionally, it displays favorable infrared (IR) transmittance, which is pivotal for energy-saving applications such as smart windows and solar cells that benefit from heat management capabilities.

Electrical Properties

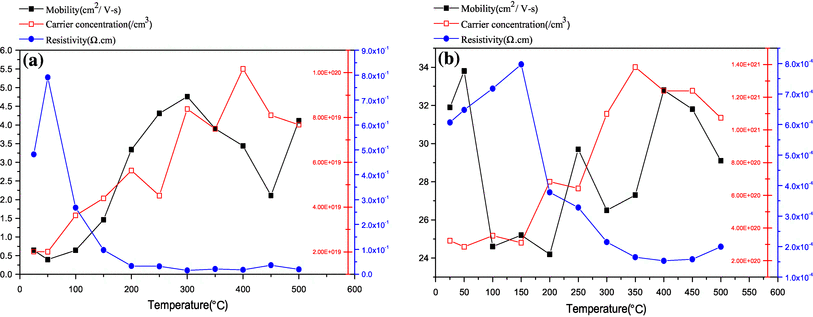

The primary attribute that makes AZO stand out is its enhanced electrical conductivity, achieved through aluminum doping. This improvement in conductivity is crucial for applications where rapid and efficient electron transport is necessary, such as in touch screens and flat-panel displays. The material’s low resistivity and high carrier mobility ensure that it performs optimally in these roles, providing a cost-effective alternative to more traditional materials like Indium Tin Oxide (ITO).

Advantages of AZO Over Other TCOs

Comparison with Indium Tin Oxide (ITO) and Other TCO Materials

AZO offers several advantages over ITO and other commonly used transparent conductive oxides. One significant benefit is cost-effectiveness. AZO uses abundant materials like zinc and aluminum, which are considerably cheaper and more available than indium, the base material for ITO. This economic advantage makes AZO a more sustainable choice for large-scale applications.

Benefits in Terms of Cost, Availability, and Performance

Apart from cost, AZO’s performance is comparable or superior to ITO in many applications. It provides good conductivity and optical transparency, essential for display technologies and solar panels. Furthermore, AZO is less brittle and more flexible than ITO, offering durability advantages for flexible electronics and touch screens.

Environmental and Practical Considerations in Manufacturing and Application

The environmental impact of using AZO is significantly lower compared to ITO. Indium mining has ecological consequences, and the rarity of the material contributes to the instability of its price. Additionally, AZO’s lower processing temperatures reduce energy consumption during manufacturing, aligning with the increasing demand for greener production processes in the tech industry.

Key Applications of AZO

Solar Cells

Aluminum-doped Zinc Oxide (AZO) plays a crucial role in the solar energy sector, particularly in photovoltaic cell manufacturing. It is used as a transparent conductive layer that allows light to reach the active layers of solar cells while also collecting and transporting electrical charges. The use of AZO in solar cells can significantly reduce costs and improve efficiency compared to cells using traditional materials like ITO.

Displays and Touch Panels

In the realm of consumer electronics, AZO is extensively utilized in the production of displays and touch panels. Its excellent transparency and conductivity make it an ideal choice for flat-panel displays, smartphones, and tablet screens. The material’s durability and flexibility also make it well-suited for emerging technologies in flexible displays.

RF-EMI Shielding and Other Uses

Beyond its primary applications, AZO is employed in RF-EMI (Radio Frequency-Electromagnetic Interference) shielding to protect electronic devices from interference and ensure consistent performance. Additionally, its antistatic properties are beneficial in various industrial applications where preventing static discharge is critical. The versatility of AZO extends to other specialized uses, such as in heated car windshields, where it helps to demist and de-ice without compromising visibility.

Technological Advances in AZO Deposition and Patterning

Deposition Techniques

The deposition of Aluminum-doped Zinc Oxide is primarily achieved through techniques like RF (Radio Frequency) and DC (Direct Current) magnetron sputtering. These methods allow for precise control over the film’s thickness and doping levels, crucial for tailoring the material’s electrical and optical properties to specific applications.

Further Reading: Everything You Need to Know About AZO Sputtering Targets

Innovations in Patterning and Etching

Advancements in patterning and etching technology have significantly enhanced the applicability of AZO in sophisticated electronic and optical devices. Techniques such as photolithography and laser etching enable the creation of intricate patterns necessary for high-resolution displays and sensitive touch panels. These developments have improved the accuracy and efficiency of AZO layers in various devices.

Recent Research Findings

Recent research in the field of AZO technologies has focused on enhancing its efficiency and functionality. Studies are exploring the optimization of doping levels to maximize conductivity without compromising transparency. Other research avenues include the integration of AZO with other materials to create hybrid structures that offer improved performance for specific technological applications, such as more efficient solar cells and smarter display technologies. These ongoing studies are pivotal in pushing the boundaries of AZO’s capabilities, promising even broader applications and efficiency in the future.

Future Prospects and Challenges

Potential Growth Areas

Aluminum-doped Zinc Oxide (AZO) is poised to expand its influence across various technological fields due to its versatile properties. Emerging sectors such as flexible electronics, wearable tech, and advanced photovoltaics present significant opportunities for AZO applications. The material’s flexibility, combined with its conductive and transparent properties, makes it ideal for next-generation devices that require bendable or wearable components.

Challenges Facing AZO Development

Despite its promising aspects, AZO faces several challenges that could hinder its widespread adoption. Technical challenges include achieving uniform doping and consistent conductivity across larger substrates, which are essential for commercial-scale production. Economically, while AZO is less expensive than alternatives like Indium Tin Oxide, the costs associated with establishing new production lines for AZO can be prohibitive. Environmentally, ensuring that AZO production and disposal do not lead to adverse effects remains a concern, necessitating ongoing research into sustainable practices.

Speculation on Future Innovations and Market Trends

The future of AZO is likely to be shaped by innovations that address its current limitations and open up new applications. Research into nanostructuring AZO or combining it with other materials to enhance its properties could lead to breakthroughs in performance and new market opportunities. Furthermore, as the demand for environmentally friendly and cost-effective materials increases, AZO’s role in industries such as renewable energy and consumer electronics is expected to grow significantly.

Conclusion

Aluminum-doped Zinc Oxide (AZO) stands out as a pivotal material in the realm of Transparent Conductive Oxides (TCOs), offering a compelling blend of optical transparency, electrical conductivity, and cost-effectiveness. As explored throughout this article, AZO presents a viable alternative to more traditional materials like Indium Tin Oxide, especially in applications requiring economic and environmental sustainability.

The future of AZO is bright, with potential expansions into emerging technologies and ongoing advancements enhancing its applicability and performance. However, addressing the technical, environmental, and economic challenges will be crucial for its continued adoption and success. The commitment to research and development in optimizing AZO’s production and application will undoubtedly play a critical role in leveraging its full capabilities.

As we move forward, the continued exploration of AZO and other TCOs will be essential in driving technological innovations, particularly in sectors like renewable energy, flexible electronics, and advanced display technologies. The progress in these areas will not only expand the applications of AZO but also contribute significantly to the advancement of modern technology.