Quick Guide

- Introduction to Sputtering Targets

- Composition and Types of Sputtering Targets

- Manufacturing Process of Sputtering Targets

- Applications of Sputtering Targets

- Factors to Consider When Choosing Sputtering Targets

- Quality Control and Testing of Sputtering Targets

- Maintenance and Handling of Sputtering Targets

- Conclusion

1. Introduction to Sputtering Targets

Sputtering targets are crucial in various industries that rely on thin-film technology, including electronics, optics, and energy production. The term “sputtering target” is derived from the material’s function in the sputtering process, a technique within physical vapor deposition (PVD). In PVD, atoms are ejected from a solid target material due to the bombardment of high-energy ions, and these atoms then deposit onto a substrate, forming a thin film. The “target” in sputtering target refers to the material that is “hit” or bombarded during deposition.

This process is vital for producing thin films, which are essential components in modern devices, from semiconductor chips to optical coatings and solar cells. As technology has evolved, so has the demand for more sophisticated sputtering targets that offer better performance, higher purity, and customized compositions to suit the specific requirements of each application.

Sputtering targets are found in a range of industries due to their versatility. They are key components in manufacturing semiconductors, magnetic materials, and photovoltaic cells, as well as producing coatings for optical devices and decorative purposes. The increasing need for precise thin films in advanced technologies continues to drive innovations in the materials and processes used for sputtering targets.

2. Composition and Types of Sputtering Targets

Sputtering targets are composed of various materials, depending on the specific application and desired thin-film properties. The choice of material can significantly affect the performance and characteristics of the final product. Below are the main types of sputtering targets used across industries:

2.1 Metal Targets

Metal targets are one of the most commonly used materials in sputtering due to their excellent thermal and electrical conductivity. They are often employed in applications where conductive films are necessary, such as semiconductor manufacturing and electrical components.

- Pure Metal Targets: Materials such as aluminum (Al), copper (Cu), nickel (Ni), gold (Au), and silver (Ag) are commonly used. Aluminum, for instance, is widely applied in semiconductor devices for metal interconnect layers, while gold and silver are valued for their conductivity and reflectivity in optical devices.

- Alloy Targets: Alloys are formed by combining two or more metals to create materials with enhanced or specific properties. Titanium aluminum (TiAl) alloys are often used for hard coatings in cutting tools, while copper aluminum (CuAl) alloys are used to provide corrosion resistance along with conductivity.

2.2 Ceramic Targets

Ceramic materials are frequently used in applications requiring high durability, chemical stability, and resistance to heat and wear. These materials are typically non-conductive, making them ideal for optical coatings and protective layers.

- Oxide Targets: Common oxide materials include aluminum oxide (Al₂O₃) and titanium dioxide (TiO₂). These are often used in the production of coatings that require high corrosion resistance, such as protective layers in optical lenses or display screens.

- Nitride Targets: Aluminum nitride (AlN) and silicon nitride (Si₃N₄) are nitride-based materials frequently used for their exceptional thermal conductivity and electrical insulation properties. These materials are ideal for high-temperature applications where thermal management is critical, such as in electronics and aerospace components.

- Carbide Targets: Materials like silicon carbide (SiC) and tungsten carbide (WC) are valued for their extreme hardness and resistance to wear. These targets are often used to create durable coatings in applications such as cutting tools or automotive components.

2.3 Compound Targets

In addition to metals and ceramics, compound materials are used in sputtering targets to achieve specific thin-film properties:

- Silicide Targets: Silicide targets, such as titanium silicide (TiSi₂) and tungsten silicide (WSi₂), are critical in semiconductor manufacturing. These materials offer excellent electrical conductivity and are commonly used in integrated circuits for forming contact and interconnect layers.

- Fluoride Targets: Fluoride materials like calcium fluoride (CaF₂) and magnesium fluoride (MgF₂) are used in optical coatings for their high transparency in the UV and infrared spectra. These targets are essential in producing optical devices like lenses and coatings for lasers.

- Sulfide Targets: Sulfide materials such as zinc sulfide (ZnS) and molybdenum disulfide (MoS₂) are used in thin films for photovoltaic cells and lubricating coatings. ZnS is also a key material in optical and display applications due to its transparency.

- Boride Targets: Boride materials like silicon boride (BSi) and titanium boride (TiB₂) are known for their high hardness and thermal stability. They are commonly used in high-temperature applications and semiconductor industries where durable coatings are needed.

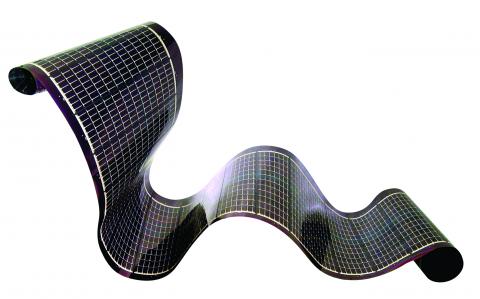

- Selenide Targets: Selenide materials, such as copper indium gallium selenide (CIGS) and zinc selenide (ZnSe), are widely used in solar cells and infrared optical devices. CIGS targets are crucial for high-efficiency thin-film solar panels, while ZnSe is used in lenses and windows for infrared applications.

- Telluride Targets: Telluride compounds like cadmium telluride (CdTe) and bismuth telluride (Bi₂Te₃) are extensively used in thermoelectric devices and photovoltaic cells. CdTe is a significant material in solar panels, while Bi₂Te₃ is used for energy harvesting in thermoelectric generators.

- Rare Earth Targets: Rare earth elements, such as gadolinium (Gd), neodymium (Nd), and yttrium (Y), are used in sputtering targets for applications requiring magnetic, luminescent, and catalytic properties. These materials are critical in producing advanced magnets, lighting technologies, and high-performance coatings.

2.4 Functional and Application-Specific Targets

These targets are categorized by their functions or the applications they are used in, rather than their chemical composition:

- Magnetic Materials: Magnetic sputtering targets, such as iron (Fe) and nickel-iron (NiFe), are commonly used in data storage applications, helping to create the magnetic layers used in hard drives and other memory devices.

- Semiconductor Targets: Silicon (Si) and germanium (Ge) are key materials in the electronics industry, particularly for integrated circuits and infrared devices. These semiconductor targets enable the deposition of thin films essential for creating electronic components and sensors.

- Composite Targets: Composite materials combine different types of materials, such as metals and ceramics, to provide a balance of properties. For instance, combining metal and ceramic components in a composite target can produce films that are both conductive and wear-resistant, useful in applications such as protective coatings for electronics.

3. Manufacturing Process of Sputtering Targets

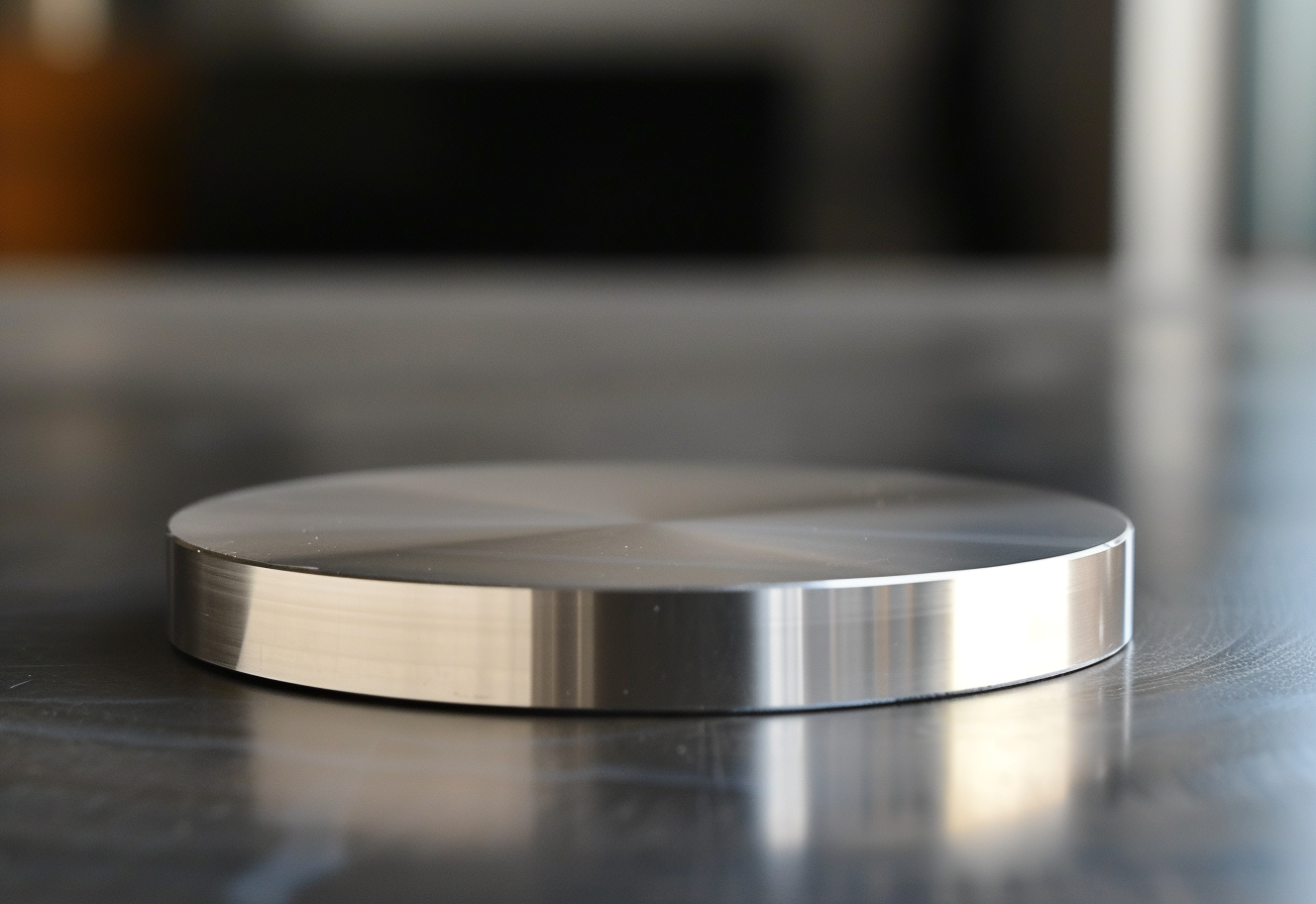

The manufacturing process of sputtering targets is crucial to achieving the desired material properties, such as purity, density, and grain structure. The choice of manufacturing method largely depends on the type of material being used and the specific requirements of the application. Below are the common techniques and workflows involved in the production of sputtering targets:

3.1 Manufacturing Techniques

Several manufacturing methods are used to produce sputtering targets, each chosen based on the material type and desired properties. Common methods include:

- Melting and Casting: This method is commonly used for metal targets. The raw metal materials are melted in a vacuum or controlled atmosphere to prevent contamination, and then cast into molds of the desired shape. Vacuum casting helps in achieving high purity and low porosity, which is important for producing high-quality sputtering targets.

- Sintering: In this method, powdered materials are compacted and then heated below their melting point to form a solid target. Sintering is often used for ceramic and compound targets, such as oxides and carbides. This process allows manufacturers to control the target’s density and microstructure, which are critical for uniform sputtering performance.

- Hot Isostatic Pressing (HIP): HIP is used to increase the density of materials by applying high pressure and temperature simultaneously. This method is particularly beneficial for ceramic or composite targets that require high density and low porosity. It also helps improve the overall mechanical properties and reduce defects.

- Cold Isostatic Pressing (CIP): Similar to HIP but conducted at room temperature, CIP is used primarily for the preliminary formation of powdered targets before sintering. It allows for the creation of high-density preforms, which are then further processed to improve their final properties.

3.2 Process Workflow

The typical process for manufacturing sputtering targets involves several key steps, each of which contributes to the final product’s performance:

- Material Preparation: The raw materials are first selected based on their purity and composition. For metal targets, this involves melting and alloying, while for ceramic and compound targets, powders are prepared through grinding and mixing.

- Shaping: Depending on the material type and final shape required, the target is formed through methods like casting, pressing, or extrusion. Metal targets are typically cast into molds, while ceramic and composite materials are compacted into their final shape using pressing techniques.

- Sintering and Pressing: For powdered materials, sintering is a key step that helps consolidate the particles into a dense, solid target. For metal and some composite targets, hot isostatic pressing can be used to further enhance density and reduce any internal voids or imperfections.

- Machining and Surface Treatment: After the target has been sintered or pressed, machining processes are used to achieve the precise dimensions and surface finish required. Lathes, grinders, and milling machines are used to ensure that the target meets the exact specifications necessary for the sputtering process. Surface treatments such as polishing or coating may be applied to further enhance performance.

- Quality Control: Each sputtering target undergoes a series of tests to ensure it meets the required standards for purity, density, and surface finish. X-ray fluorescence (XRF), inductively coupled plasma (ICP) analysis, and optical microscopy are common testing methods used to verify material properties and detect any defects.

3.3 Control of Grain Structure

Grain structure is a critical aspect of sputtering target performance. The grain size and orientation can impact the uniformity of thin films and the rate at which the material sputters. Finer grain sizes are preferred for achieving consistent deposition rates, as they provide a more uniform material ejection during the sputtering process. In addition, controlling the grain orientation—ideally aiming for equiaxed grains (where grains have roughly the same dimensions in all directions)—helps improve the stability of the sputtering process, reducing the variability in film thickness.

To control the grain structure, manufacturers use advanced processing techniques such as:

- Powder metallurgy for producing fine-grain ceramics and composites.

- Controlled cooling rates during casting or sintering to influence the final grain size.

- Post-processing treatments like annealing, which can refine the grain structure and enhance material properties.

By carefully controlling the manufacturing process, manufacturers can produce sputtering targets that meet stringent requirements for modern thin-film applications, ensuring optimal performance, longevity, and reliability in their respective industries.

4. Applications of Sputtering Targets

Sputtering targets are integral to a variety of high-tech industries, where their specific properties help form thin films on various substrates. Different materials are selected based on the unique requirements of each application, such as conductivity, durability, and chemical stability. Below are some of the key industries where sputtering targets play a crucial role:

4.1 Semiconductor Manufacturing

In the semiconductor industry, sputtering plays a crucial role in depositing thin metal and dielectric films on silicon wafers, which form the essential components of integrated circuits and other electronic devices. Materials such as aluminum are commonly used for metal interconnect layers due to their excellent conductivity, making them ideal for forming electrical connections between components on a chip. Additionally, titanium is frequently applied as a barrier or adhesion layer between metal interconnects and silicon substrates, helping to prevent diffusion and ensuring reliable electrical performance.

4.2 Data Storage (Hard Drive Manufacturing)

The data storage industry relies heavily on sputtering to produce thin films with magnetic properties essential for storing digital information on hard drives and other magnetic storage devices. Cobalt, for example, is often used to deposit magnetic layers on hard drive platters, which enable high-density data storage. To improve corrosion resistance and increase coercivity, cobalt is sometimes alloyed with chromium to create a material that ensures long-term data stability and enhances the performance of magnetic recording layers.

4.3 Optical Devices

Sputtering is widely employed in the production of optical coatings, which are crucial for enhancing the performance of lenses, mirrors, and other optical components by controlling reflectivity and transmission. For example, silicon dioxide is a popular material for anti-reflective coatings on optical lenses, as it effectively reduces light reflection and improves clarity, which is essential for high-precision instruments like microscopes and cameras. Another important material in this sector is indium tin oxide, which is used to create transparent conductive films in touchscreens and LCDs, combining electrical conductivity with optical transparency to support the functionality of modern electronics.

4.4 Solar Cells

In the solar energy industry, sputtering targets are used extensively to produce thin-film solar cells, where they help form the various layers necessary for efficient energy conversion. Aluminum-molybdenum alloys, for instance, are applied as back electrodes, providing excellent conductivity and strong adhesion to the substrate. The addition of molybdenum enhances the mechanical properties and corrosion resistance of the layer. Another widely used material in this sector is copper indium gallium selenide (CIGS), a highly efficient absorber material in thin-film solar cells, which is sputtered onto the active layer to convert sunlight into electricity with high efficiency.

4.5 Protective and Decorative Coatings

Sputtering is also commonly used to produce protective and decorative coatings on surfaces such as metals, glass, and ceramics. These coatings not only enhance the durability of the material but also improve its aesthetic appeal. Titanium nitride, for example, is often applied as a gold-colored, wear-resistant coating on items like jewelry, watches, and high-end tools. Its appealing visual effect is matched by its excellent hardness and resistance to corrosion. In addition, chromium is widely used for applying corrosion-resistant coatings to glass and metal surfaces, such as automotive parts and architectural glass, where it protects against environmental damage while maintaining a sleek, polished appearance.

5. Factors to Consider When Choosing Sputtering Targets

The selection of sputtering targets plays a critical role in determining the quality and performance of the thin films produced. Several key factors need to be taken into account to ensure optimal results, particularly in applications requiring precise control over film properties such as thickness, uniformity, and adhesion.

5.1 Target Purity and Its Impact on Coating Quality

One of the most important considerations when choosing a sputtering target is its purity. High-purity targets are essential for producing high-quality coatings, as impurities can cause significant issues during the deposition process. For example, contaminants such as oxygen and water vapor can negatively affect the adhesion of the thin film to the substrate, leading to weak, non-uniform coatings that may peel off or degrade over time. This is particularly problematic in semiconductor applications, where even trace amounts of impurities can disrupt electrical conductivity. Copper targets, for instance, must maintain a low sulfur content to avoid micro-cracks and electrical discharge during deposition, which can result from excess sulfur impurities. As a result, high-purity targets (often 99.99% or higher) are critical for achieving reliable and durable coatings.

5.2 Target Density and Its Role in Film Uniformity

The density of the sputtering target also plays a significant role in determining the quality of the thin film. Higher density targets have fewer pores, leading to more consistent and uniform film deposition. Low-density targets, on the other hand, often have a porous structure that can introduce impurities like oxygen into the film, resulting in defects such as cracks, non-uniform thickness, and even electrical discharge problems. For applications that require extreme precision, such as in the semiconductor and optics industries, targets with densities above 98% are often preferred to ensure consistent sputtering rates and film quality. In the case of powder metallurgy targets, a density of 97% or higher is typically recommended to ensure stable deposition under high-temperature and high-pressure conditions.

5.3 Grain Size and Its Influence on Sputtering Rate

The grain size of the sputtering target affects the sputtering rate and the overall efficiency of the deposition process. Targets with smaller grain sizes tend to sputter more uniformly and at a faster rate because the fine grain boundaries are more easily eroded by the sputtering ions. This makes them ideal for high-throughput applications where deposition speed is critical. Conversely, larger grain sizes may result in uneven sputtering, which can lead to variations in film thickness and performance. Therefore, fine-grained targets are often used in industries where precision and consistency are paramount, such as microelectronics and optical coatings.

5.4 Target Shape and Its Impact on Utilization Efficiency

The shape of the sputtering target is another factor that influences the deposition process. There are two main shapes used in sputtering systems: planar targets and rotating (cylindrical) targets. Planar targets are typically flat and are used in applications that involve smaller substrates or where uniformity across a flat surface is essential. However, rotating targets are often preferred for large-area coatings, as they offer higher material utilization rates and longer service life. By rotating during the sputtering process, these targets expose a larger surface area, leading to more efficient material usage and less waste. This is particularly useful in applications such as large-scale display manufacturing, where material efficiency is crucial for cost-effective production.

5.5 Uniformity and Its Impact on Film Performance

Target uniformity is critical for ensuring consistent film thickness and properties across the entire substrate. Variations in the material composition or density across the target can lead to non-uniform deposition, resulting in films with inconsistent thickness or undesirable electrical or optical characteristics. This can significantly affect the performance of the final product, especially in precision applications like semiconductors or high-performance optical components. Ensuring that the target material is evenly distributed and free from defects is crucial for maintaining the high quality and performance of the deposited films.

5.6 Controlling Production Parameters to Enhance Target Performance

The production parameters during target manufacturing, such as temperature, pressure, and the use of inert gases, are critical for controlling the quality of the sputtering target. For instance, techniques like vacuum hot pressing and hot isostatic pressing (HIP) are employed to increase the target density and eliminate voids or impurities, thereby improving the overall sputtering performance. Cold isostatic pressing (CIP) is commonly used for shaping and densifying powdered materials before final sintering, which helps achieve the required density and mechanical properties. Additionally, carefully controlling the cooling rate during the production process can help refine the grain structure, further improving sputtering efficiency and film uniformity.

6. Quality Control and Testing of Sputtering Targets

Ensuring the quality of sputtering targets is crucial for achieving consistent, high-performance thin films. As these targets are used in highly specialized applications, any defect or impurity can significantly affect the resulting film’s performance. Rigorous quality control and testing processes are implemented to maintain high standards in sputtering target manufacturing, ensuring that the targets meet the precise requirements of industries such as semiconductors, optics, and solar energy.

6.1 Material Purity Testing

The purity of sputtering targets is one of the most critical factors affecting thin-film deposition. Even trace amounts of impurities can cause defects in the thin film, leading to issues such as reduced conductivity, poor adhesion, or the introduction of unwanted chemical elements. To maintain the highest levels of purity, advanced testing methods are used:

- X-Ray Fluorescence (XRF): XRF is commonly used to determine the elemental composition of sputtering targets. This non-destructive technique allows for the identification and quantification of both major and trace elements in the material, ensuring that no harmful impurities are present.

- Inductively Coupled Plasma (ICP) Analysis: ICP is another method used to analyze the composition of materials with a high degree of accuracy. It is particularly useful for detecting trace metal impurities in targets.

- Glow Discharge Mass Spectrometry (GDMS): GDMS is employed to detect ultra-trace levels of impurities in sputtering targets. This highly sensitive method is capable of identifying impurities at parts-per-billion (ppb) levels, making it ideal for applications where even the smallest contaminants can disrupt the thin-film process, such as in semiconductor manufacturing.

Related Article: Effect of Sputtering Target Purity on Large-Area Coating Production

6.2 Size and Shape Testing

Ensuring that the sputtering target has the correct dimensions and shape is essential for proper integration into the sputtering system. Any deviation from the specified size can affect the uniformity of the sputtering process or even lead to equipment malfunction. To verify that targets meet the exact specifications, precise measurement tools are used:

- Optical Profilometry: This technique is used to measure the surface profile and overall dimensions of the target. Optical profilometry provides accurate, high-resolution measurements to ensure that the target fits the equipment and performs consistently during the sputtering process.

- Coordinate Measuring Machines (CMM): CMMs are employed to measure the geometric dimensions of the target. These machines use a probe to physically touch the target and collect highly accurate measurements of its size and shape, ensuring that it conforms to the required specifications.

6.3 Surface Finish Testing

The surface finish of the sputtering target is critical to the sputtering process. An uneven or rough surface can lead to inconsistent material ejection, which in turn can affect the uniformity of the thin film. Additionally, surface imperfections may introduce unwanted particles or contamination into the deposition process. To ensure a smooth and defect-free surface, manufacturers employ various testing methods:

- Scanning Electron Microscopy (SEM): SEM is used to inspect the surface morphology of the target at a high resolution. It allows manufacturers to detect surface defects such as cracks, pits, or contamination that may affect the sputtering process.

- Atomic Force Microscopy (AFM): AFM provides even more detailed surface analysis at the nanoscale level. It is used to measure the surface roughness and ensure that the target meets the required surface finish standards for uniform material deposition.

- Optical Microscopy: While less detailed than SEM or AFM, optical microscopy is often used for initial surface inspections to detect larger imperfections or contamination on the target surface.

6.4 Damage and Contamination Testing During Transport and Storage

Sputtering targets must remain free from damage and contamination during transport and storage to ensure optimal performance. Any contamination from dust, oils, or other environmental factors can degrade the target’s effectiveness and lead to poor-quality films. Quality control measures include:

- Visual Inspection: Before use, targets are visually inspected for any signs of physical damage, such as cracks or scratches, that may have occurred during transportation or handling. This is often the first step in quality assurance before more detailed testing is conducted.

- Leak Testing: For targets that are vacuum-sealed, leak testing is performed to ensure that the packaging is intact and no air or moisture has entered the package. This is particularly important for targets that are sensitive to oxidation or moisture, such as certain metals and alloys.

- Vacuum Packaging: Many high-purity targets are vacuum-sealed to protect them from environmental contaminants. Vacuum packaging prevents dust, moisture, and other particles from contaminating the surface of the target, which could affect its performance during the sputtering process.

7. Maintenance and Handling of Sputtering Targets

Proper maintenance and handling of sputtering targets are essential to ensure optimal performance, longevity, and the quality of the thin films produced. Mishandling or improper storage can lead to contamination, physical damage, or degradation of the target’s properties, which will adversely affect the sputtering process and the films deposited. Below are the best practices for maintaining and handling sputtering targets:

7.1 Storage Requirements

Sputtering targets must be stored in a clean, dry environment to prevent contamination from dust, moisture, or other environmental factors. Contamination, particularly from water vapor or dust, can affect the target surface, leading to film defects during the sputtering process. Proper storage practices include:

- Cleanroom Conditions: Targets should ideally be stored in a cleanroom environment, especially for high-purity targets used in sensitive applications like semiconductor manufacturing. Cleanrooms minimize exposure to contaminants and keep the targets in a controlled atmosphere.

- Temperature and Humidity Control: Avoid exposing targets to high humidity or temperature fluctuations, as these can promote oxidation or corrosion of the target material. Materials like copper and aluminum are particularly sensitive to these environmental conditions and may require storage in vacuum-sealed packaging to preserve their purity.

- Vacuum Sealing: High-purity or reactive materials, such as those used in semiconductor or optical industries, should be vacuum-sealed when stored to avoid contamination and oxidation. This protects the target’s surface from exposure to moisture and air, ensuring that its properties remain stable over time.

7.2 Handling Precautions

Proper handling of sputtering targets is crucial to prevent physical damage or contamination, both of which can have significant effects on thin-film quality. Best handling practices include:

- Use of Clean Gloves and Tools: Operators should always wear clean, lint-free gloves when handling targets to avoid transferring oils, dirt, or other contaminants from the skin. Additionally, only clean, dedicated tools should be used to move or mount the target.

- Avoiding Surface Contact: Minimize direct contact with the target’s surface. Fingerprints, oils, and other residues can cause contamination that will impact the uniformity and adhesion of the thin film. Even minor surface imperfections introduced during handling can lead to defects in the sputtering process, reducing the overall quality of the film.

- Careful Mounting: When mounting the target into the sputtering system, it is important to avoid excessive force that could cause cracking or chipping. Many targets, especially ceramic or composite materials, are brittle and can break under improper handling. Using the proper mounting hardware and techniques ensures the target is securely fastened without causing damage.

7.3 Regular Inspection and Cleaning

Frequent inspection and cleaning of sputtering targets are necessary to maintain their performance throughout their lifecycle. Depending on usage, the target surface may accumulate debris, oxidation, or develop wear that can affect the sputtering process. Key practices include:

- Surface Inspection: Regular visual inspections of the target surface can identify any cracks, chips, or areas of wear that could interfere with sputtering. Detecting damage early allows for target replacement before it impacts the quality of the thin films.

- Cleaning: Periodic cleaning of the target surface helps remove any buildup of contaminants or oxidation. This is especially important for materials like copper, which are prone to oxidation. The cleaning process must be carried out carefully, using appropriate solvents and cleaning methods to avoid introducing new contaminants or damaging the surface.

- Monitoring Target Wear: Over time, the target material will naturally wear down due to the sputtering process. Monitoring the target’s wear rate is crucial for determining when the target needs to be replaced. Excessive wear can lead to inconsistent sputtering, reduced film quality, and increased costs due to wasted material.

7.4 Preventing Damage During Transport

Sputtering targets, especially those made from brittle materials like ceramics or certain composites, are vulnerable to damage during transportation. To prevent breakage or contamination, targets should be packaged securely in protective materials and handled with care. Best practices for transport include:

- Cushioned Packaging: Use protective packaging materials such as foam or bubble wrap to prevent the target from moving or experiencing impact during transport.

- Fragile Labeling: Label packages containing sputtering targets as fragile to ensure that shipping handlers treat them with the necessary care.

- Avoiding Vibrations and Shocks: Sensitive targets, particularly large or fragile ones, should be transported using specialized carriers that minimize exposure to vibrations and shocks, which could cause cracking or other damage.

8. Conclusion

Sputtering targets play a critical role in the production of thin films, which are essential components in a wide range of industries, including semiconductors, data storage, optics, solar energy, and decorative coatings. The materials used in sputtering targets, as well as the processes employed to manufacture and handle them, directly impact the quality and performance of the thin films deposited.

Key factors such as target purity, density, grain size, and surface finish must be carefully considered during selection to ensure that the target meets the specific requirements of the application. Moreover, rigorous quality control and testing measures are vital to detect impurities, ensure correct dimensions, and maintain a smooth surface, all of which contribute to achieving high-quality thin films. Proper maintenance, handling, and storage of sputtering targets are equally important to ensure longevity and consistent performance, minimizing the risk of contamination or damage.

As a leading supplier of sputtering targets, Stanford Advanced Materials (SAM) offers a wide range of high-quality sputtering targets for various industries. SAM specializes in providing customized solutions tailored to meet specific requirements, ensuring that your thin film deposition processes achieve optimal results. Whether you are in the semiconductor, solar energy, or optics industry, SAM is dedicated to providing sputtering targets that meet the highest standards of quality and performance.

For more information or to discuss your specific sputtering target needs, contact Stanford Advanced Materials (SAM) today to explore their wide selection of materials and services.

Send An Inquiry