Introduction

In the realm of thin-film deposition technologies, Palladium Sputter Targets have emerged as key components, shaping advancements in various industries. This comprehensive guide aims to provide an in-depth understanding of Palladium Sputter Targets, covering their properties, manufacturing processes, and wide-ranging applications.

Properties of Palladium Sputter Targets

Palladium, a transition metal belonging to the platinum group, possesses a distinct set of properties that make Palladium Sputter Targets highly sought after in thin-film deposition processes.

Excellent Electrical Conductivity:

Palladium’s exceptional electrical conductivity is a standout feature, making it an ideal material for thin-film deposition in the electronics industry. The high conductivity of palladium thin films contributes to the enhanced performance and reliability of electronic components, such as capacitors and resistors.

Catalytic Activity:

The catalytic properties of palladium are harnessed in various applications, especially in catalysis and sensors. Palladium Sputter Targets play a vital role in the production of catalytic converters for automobiles, where thin films of palladium facilitate efficient conversion of harmful emissions. Additionally, palladium thin films are integral to the development of sensors, including gas sensors and biosensors, owing to their catalytic sensitivity.

Resistance to Oxidation:

Palladium’s inherent resistance to oxidation is a key factor in its enduring popularity. This resistance ensures the stability of Palladium Sputter Targets during the sputter deposition process and contributes to the longevity of the thin films in diverse applications. The ability of palladium to maintain its integrity in varying environmental conditions adds to its appeal in thin-film deposition technologies.

Hydrogen Absorption:

A unique property of palladium is its ability to absorb and release hydrogen at room temperature. This characteristic makes Palladium Sputter Targets indispensable in hydrogen storage applications. Thin films of palladium contribute to the development of materials that efficiently store and release hydrogen, advancing the possibilities in clean energy storage.

X-ray Absorbance:

The exceptional X-ray absorbance properties of palladium make it an ideal material for medical imaging applications. Palladium Sputter Targets play a crucial role in creating thin films for X-ray detectors, enhancing the accuracy and resolution of diagnostic imaging technologies. This property positions palladium as a cornerstone in the advancement of medical diagnostics.

Versatility in Optical Coatings:

Palladium’s versatile optical properties make Palladium Sputter Targets invaluable in the production of thin films for optical coatings. Whether applied to lenses, mirrors, or other optical devices, these coatings enhance performance and durability. The adaptability of palladium in optical applications further solidifies its role in shaping advancements across various industries.

Manufacturing Palladium Sputter Targets

The journey of a Palladium Sputter Target begins with the selection of high-purity palladium. The quality of the initial material is paramount, as impurities can compromise the performance of the target in the sputter deposition process. The manufacturing process involves several key stages:

Step 1: Material Selection

High-purity palladium is chosen as the base material for Palladium Sputter Targets. This ensures the starting material meets stringent purity requirements, a critical factor in achieving optimal thin-film deposition outcomes.

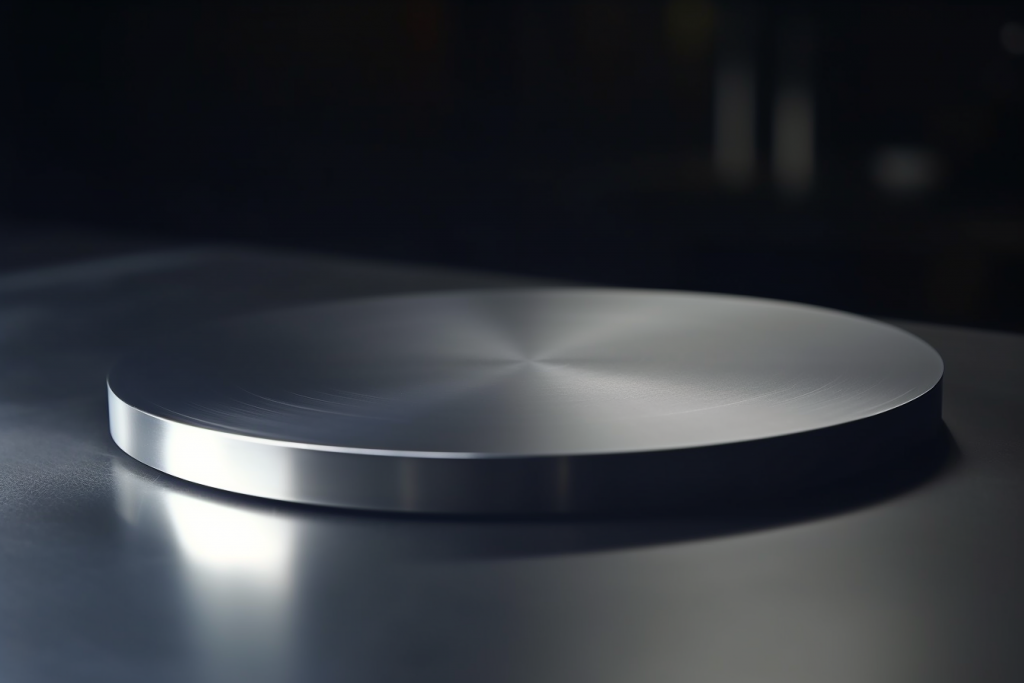

Step 2: Melting and Casting

The selected palladium undergoes a meticulous process of melting and casting, shaping it into the desired form, often a disc or rectangular plate. Precision in casting is crucial to achieving uniformity in the target’s composition and structure.

Step 3: Heat Treatment

Heat treatment is applied to the cast palladium, enhancing its mechanical properties and ensuring the target’s stability during the sputter deposition process. This step also helps alleviate residual stresses in the material.

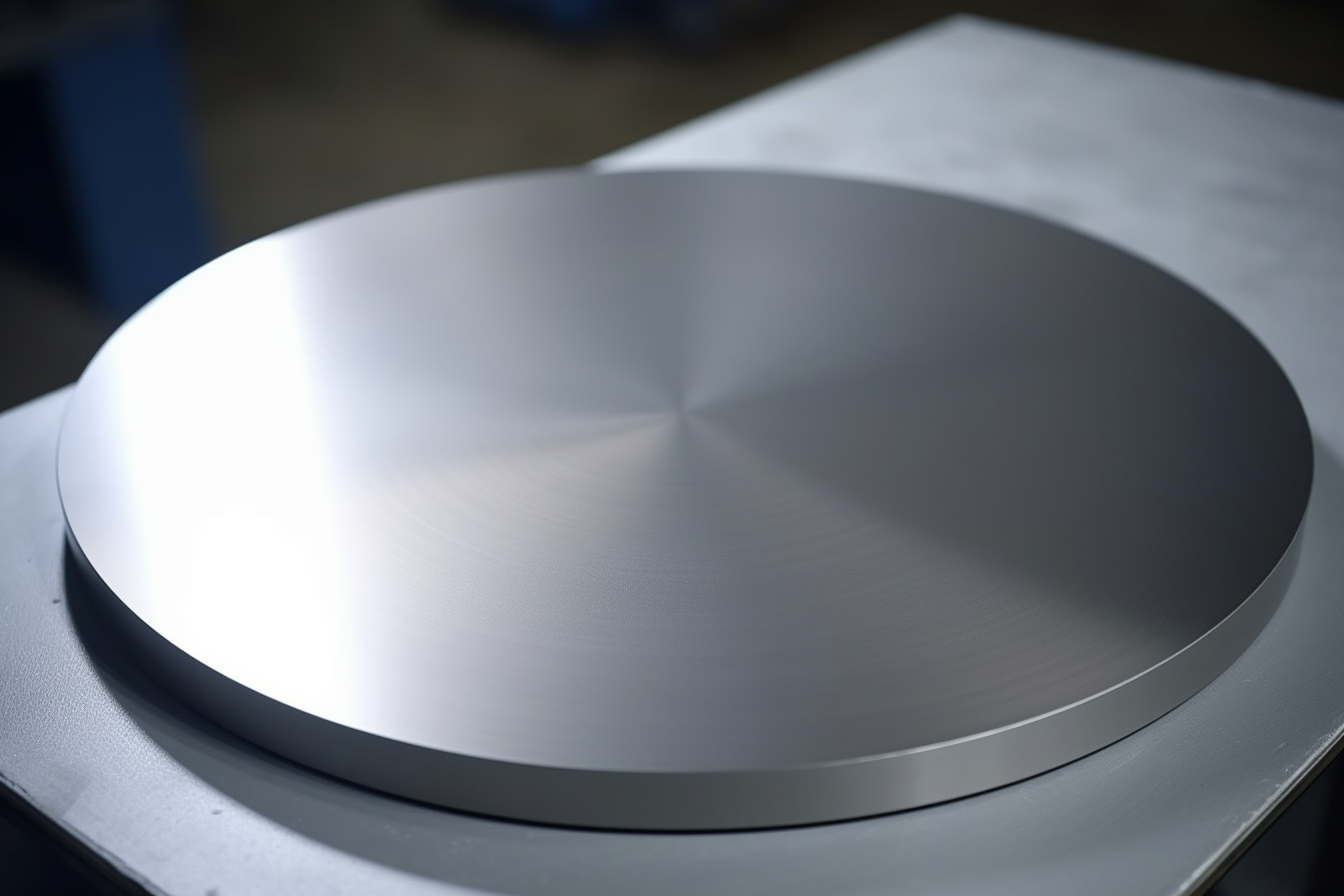

Step 4: Machining and Surface Finishing

Precision machining is employed to achieve the final shape of the Palladium Sputter Target. The surface is meticulously finished to meet the specifications required for sputter deposition, guaranteeing a smooth and even film deposition process.

Applications of Palladium Sputter Targets

Electronics Industry:

Palladium Sputter Targets find extensive applications in the electronics industry, particularly in the production of components such as capacitors and resistors. The thin films deposited by palladium targets contribute to the reliability and performance of electronic devices.

Catalysis and Sensors:

The catalytic properties of palladium make Palladium Sputter Targets invaluable in catalysis applications, including the production of catalytic converters for automobiles. Additionally, palladium thin films play a crucial role in the development of sensors for various industries, including gas sensors and biosensors.

Hydrogen Storage:

Palladium’s unique ability to absorb and release hydrogen at room temperature makes Palladium Sputter Targets instrumental in hydrogen storage applications. Thin films of palladium are used in the creation of materials that can store and release hydrogen efficiently.

Medical Imaging:

The excellent X-ray absorbance properties of palladium make it an ideal material for medical imaging applications. Palladium Sputter Targets are used to create thin films for X-ray detectors, contributing to advancements in diagnostic imaging technologies.

Fuel Cells:

Palladium Sputter Targets play a vital role in the production of thin films for fuel cells. These thin films enhance the performance and efficiency of fuel cells, contributing to the development of cleaner and more sustainable energy sources.

Optical Coatings:

The optical properties of palladium make Palladium Sputter Targets essential in the production of thin films for optical coatings. These coatings find applications in lenses, mirrors, and other optical devices, enhancing their performance and durability.

Conclusion

In conclusion, Palladium Sputter Targets stand as versatile and crucial elements in the world of thin-film deposition. From their unique properties to the meticulous manufacturing processes and diverse applications across industries, the significance of Palladium Sputter Targets in advancing technology cannot be overstated. As industries continue to evolve, the role of Palladium Sputter Targets in shaping the future of materials science and technological innovation remains at the forefront.

Click to Inquiry High Quality Palladium Target