Introduction

Synthetic diamonds, particularly those produced by Chemical Vapor Deposition (CVD), represent a significant technological advancement that blends centuries of curiosity and modern scientific ingenuity. Historically, diamonds have been highly sought after not only for their aesthetic value but also for their remarkable physical properties. Researchers like Isaac Newton have studied these properties, paving the way for today’s technological applications.

CVD and High Pressure High Temperature (HPHT) are the two principal methods used to create synthetic diamonds. Each method recreates the extreme conditions under which natural diamonds form, but it is the CVD process that excels in versatility and control over the material properties. By depositing carbon atoms onto a substrate in a controlled environment, CVD allows for the production of diamond wafers with unprecedented purity and customizable characteristics.

These advances in material science have not only made it possible to enhance the intrinsic properties of diamonds but have also made them more accessible and beneficial across various industrial applications. As we delve deeper into the specifics of CVD diamond production and applications, the profound impact of this technology becomes evident, marking a new era in both scientific research and industrial application.

Production of CVD Diamond Wafers

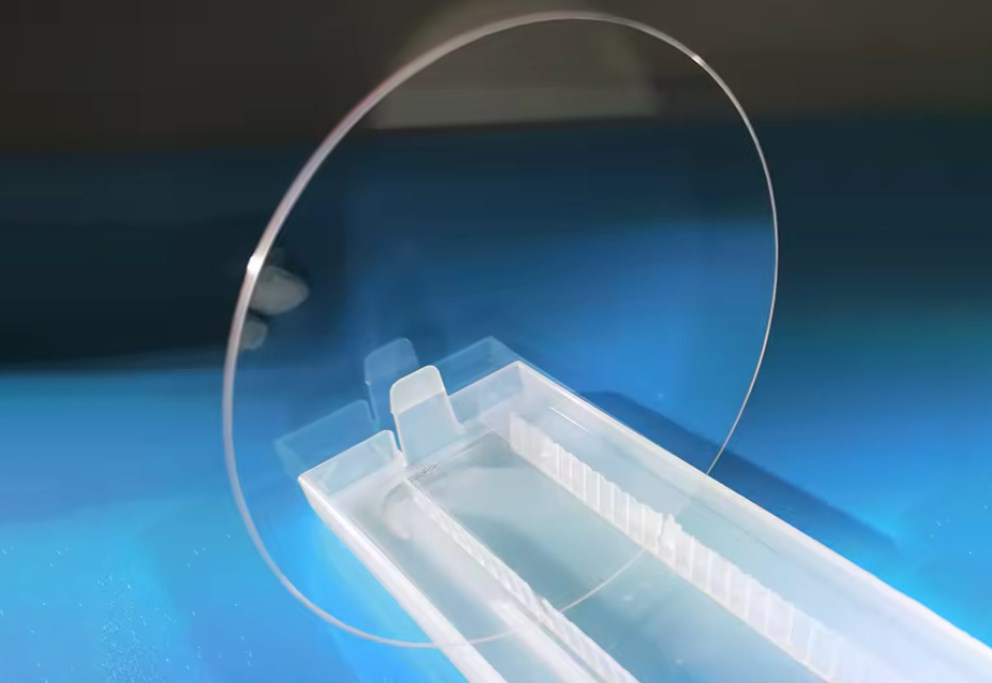

The production of CVD diamond wafers is a testament to the sophistication of modern chemistry and engineering, showcasing how carbon atoms can be meticulously layered into diamond structures on a wafer scale. Unlike the HPHT method, which replicates the natural formation conditions of diamonds by applying extreme pressure and heat, the CVD process emphasizes vapor-phase growth. This method involves introducing a mixture of a hydrocarbon gas, such as methane, and hydrogen into a vacuum chamber heated to extreme temperatures.

Within this chamber, gases are activated by energy sources like microwaves, plasma arcs, or hot filaments. This activation causes the carbon atoms to dissociate from the gases and gradually deposit onto a substrate, typically made of silicon or existing diamond surfaces. This deposition occurs in layers, allowing for the structured growth of diamond in a controlled manner. The precise control offered by the CVD technique enables the growth of diamond wafers with minimal defects and exceptional uniformity, which are critical for high-quality applications.

The adaptability of the CVD process also extends to the ability to “dope” the diamond during its formation by introducing other elements such as boron or nitrogen. This doping alters the electrical, optical, or thermal properties of the diamond, enhancing its suitability for a broad range of applications beyond what natural diamonds can offer.

Moreover, advancements in CVD technology have streamlined the production process, reducing costs and improving the efficiency of diamond synthesis. This economic advantage makes CVD diamond wafers a more accessible option for industries that require the unique properties of diamond but at a lower cost and higher consistency than what can be achieved with natural or HPHT-produced diamonds.

Properties of CVD Diamond Wafers

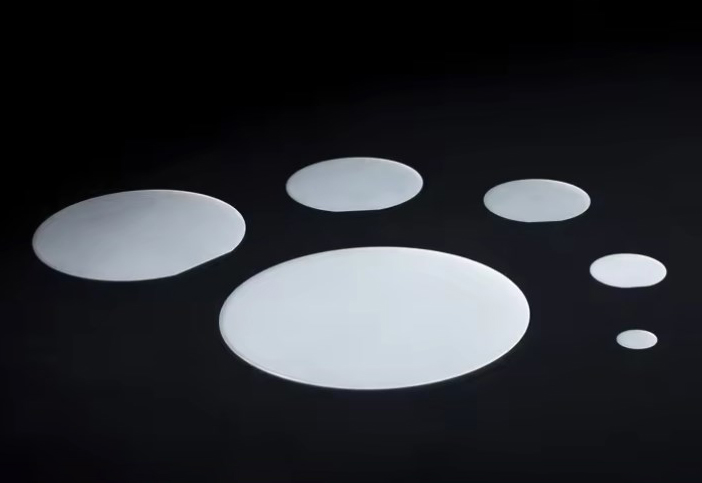

CVD diamond wafers exhibit a suite of remarkable properties that make them indispensable in various high-tech applications. These properties include exceptional hardness, superior thermal conductivity, optical transparency, and chemical inertness, making them highly sought after in diverse industrial sectors.

Exceptional Hardness: CVD diamonds are renowned for their hardness, which is comparable to that of natural diamonds. This makes them ideal for use in cutting tools, wear-resistant coatings, and other applications where durability is crucial.

Superior Thermal Conductivity: One of the most notable properties of CVD diamond wafers is their thermal conductivity, which can be as high as 1800W/m.K. This exceptional characteristic allows them to efficiently dissipate heat, making them essential in electronics and semiconductor devices to prevent overheating.

Optical Transparency: CVD diamonds can be engineered to be highly transparent across a wide range of wavelengths, from ultraviolet to infrared. This makes them suitable for optical lenses, laser windows, and other high-precision optical components.

Chemical Inertness: Their resistance to chemical reactions ensures that CVD diamond wafers remain stable and functional in harsh chemical environments, ideal for chemical processing equipment and sensors.

Electrical Properties: By incorporating specific impurities during the CVD process, diamonds can be tailored to exhibit semiconducting, insulating, or even superconducting properties. This flexibility allows CVD diamonds to be customized for a wide range of electronic applications.

Applications Across Various Industries

The unique properties of CVD diamond wafers have led to their widespread adoption across multiple industries, transforming traditional practices and enabling new technological advancements. Here are some of the key applications:

Electronics: In the electronics industry, CVD diamond wafers are used to fabricate heat sinks that effectively manage the thermal load of high-power semiconductor devices. Their exceptional thermal conductivity ensures devices operate within optimal temperature ranges, enhancing performance and longevity. Additionally, the ability of CVD diamonds to function as insulators or semiconductors makes them integral indeveloping electronic components.

Optics: The optical transparency of CVD diamonds across a broad spectrum makes them ideal for high-performance laser systems. They are used in manufacturing laser windows and lenses that require high durability and minimal optical distortion, crucial for precision in scientific and medical instruments.

Mechanical Applications: The unparalleled hardness of CVD diamonds makes them perfect for cutting tools and abrasive coatings. These applications benefit from the material’s wear resistance, significantly extending the life of tools and reducing manufacturing costs.

Medical Field: CVD diamond wafers are used in producing surgical instruments and dental tools, where their hardness and precision are crucial. Additionally, their biocompatibility makes them suitable for various implantable medical devices.

Semiconductor Manufacturing: The semiconductor industry utilizes CVD diamond wafers as substrates for electronic components. Their electrical properties can be tailored through doping, offering a wide range of semiconducting characteristics essential for advanced electronic devices.

Energy Sector: In energy applications, CVD diamonds are used in photovoltaic devices and as radiation detectors due to their sensitivity and stability under radiation exposure. This contributes to the development of more efficient solar energy systems and improved monitoring in nuclear facilities.

Conclusion

CVD diamond wafers represent a significant leap forward in the quest for materials that combine exceptional physical properties with versatility and sustainability. From enhancing the performance of electronic devices to enabling new medical technologies and pushing the frontiers of scientific research, the applications of these synthetic diamonds are as diverse as they are impactful. As we’ve explored, their integration into various industries has not only revolutionized existing practices but also opened the door to innovations that were previously beyond reach.

The journey of CVD diamond wafers from laboratory curiosities to industrial mainstays is a testament to the power of material science to drive progress. Looking ahead, the continued evolution of CVD technology and the expanding range of applications promise to further cement the role of synthetic diamonds in shaping our technological future. Whether it’s in creating more efficient semiconductors, pioneering new medical treatments, or exploring the unknown in quantum computing, CVD diamond wafers are poised to play a pivotal role.

In this era of rapid technological advancement, the story of CVD diamond wafers is a shining example of how innovative materials can revolutionize industries and improve our world. As researchers and engineers continue to explore the full potential of these remarkable materials, we can expect to see even more groundbreaking applications that leverage the unique properties of synthetic diamonds, illuminating the path toward a brighter, more sustainable future.

Further Reading

To deepen your understanding of CVD diamond wafers and explore broader applications and technological developments associated with Chemical Vapor Deposition, consider the following resources:

- CVD Technology’s Impact on Semiconductor Thin Film Production

This article explores how CVD technology has revolutionized the production of semiconductor thin films, highlighting its critical role in enhancing device efficiency and performance. - Advancements in CVD Techniques: Synthesizing High-Quality PBN & PG Materials

Dive into the recent advancements in CVD techniques that have enabled the synthesis of high-quality pyrolytic boron nitride (PBN) and pyrolytic graphite (PG) materials, showcasing the versatility and broad applicational scope of CVD technologies. - Temperature Differences between PVD and CVD

This resource provides a comparative analysis of the temperature regimes used in Physical Vapor Deposition (PVD) versus Chemical Vapor Deposition (CVD), offering insights into how these differences influence the deposition process and the quality of the final products.

For any other information, please visit our homepage.