1. Introduction

Biocompatible coatings are materials made to interact safely with human tissues. They do not cause harmful reactions when they come into contact with the body. Biocompatible coatings are crucial in medical implants and devices because they lower the risk of the body rejecting the implant. They also make the implants more stable and help them last longer. As medical technology progresses and as the need for durable and efficient materials grows, there are many new advancements in biocompatible coatings.

2. Types of Biocompatible Coatings

There are several types of biocompatible coatings, each offering specific benefits for different medical uses:

-

Ceramic Coatings: Hydroxyapatite is a ceramic material often used for coating bone implants. This type of coating helps the bone grow and heal while lowering the risk of rejection.

-

Polymer Coatings: Materials like Polyvinylpyrrolidone (PVP) and Polyvinyl Alcohol (PVA) are common in heart stents and catheters. These coatings help the body accept the device better and prevent blood clots from forming.

-

Metal Coatings: Titanium and gold coatings are widely used in dental and orthopedic implants. They resist corrosion and help implants bond more effectively with bone, making them last longer.

-

Biomolecular Coatings: These coatings, which can include antibodies or antimicrobial peptides, are used to fight infections and enhance the performance of implants. They are particularly useful in wound care and surgeries.

3. Recent Developments in Biocompatible Coatings

There have been several recent developments in biocompatible coatings that are making them more effective and versatile:

Nanomaterials have brought a new dimension to biocompatible coatings. These materials are extremely small, often much smaller than a human cell, and provide unique advantages. Silver nanoparticles, for instance, are used in coatings to prevent bacterial growth. This is essential in medical settings where infections can be dangerous. Such coatings help reduce complications and support faster recovery times for patients. Nanomaterials are also used in coatings that promote cell growth, which is crucial for bone implants that need to bond with existing bone.

3D Printing and Laser Deposition techniques have also opened new possibilities. They allow for custom-made implants that fit perfectly in the body. For example, 3D printing can create implants that match a patient’s specific bone structure, ensuring a better fit. Laser deposition helps apply thin, uniform coatings that provide benefits like improved wear resistance or better bonding with bone. These precise techniques make implants more comfortable and effective for patients.

Responsive Coatings are designed to react to changes in the body’s environment. These coatings can detect shifts in pH levels or temperature, which might signal an infection. When an infection is detected, the coating can release medicine directly at the site, providing immediate treatment. This approach makes the use of medication more targeted, reducing side effects and enhancing effectiveness. Responsive coatings can also respond to swelling or other changes, making them highly adaptable in various medical scenarios.

Therapeutic Coatings are another important area of progress. These coatings are designed to deliver drugs or other therapeutic agents directly to the site where they are needed. For instance, some cardiovascular stents are coated to release medication slowly over time, helping to keep arteries open and reducing the risk of further blockages. By delivering medication right where it is needed, these coatings help improve treatment outcomes and reduce the likelihood of complications.

4. Benefits and Challenges

Biocompatible coatings provide many benefits for medical implants and devices. They make implants safer by lowering the chance of the body rejecting them. These coatings also help implants connect better with tissues, which improves stability and overall function. In addition, they protect against bacterial growth and corrosion, which helps implants last longer.

However, there are also challenges. Over time, some coatings may wear down or degrade, which can make them less effective. The process of developing and applying these coatings is often complex and costly, which can limit their availability, especially in areas with fewer resources. Moreover, these coatings must pass thorough clinical testing and meet regulatory standards. This process is essential for safety but can also delay their introduction and increase costs.

5. Real-World Applications

Biocompatible coatings are already being used in many medical devices and implants, and their applications are expanding:

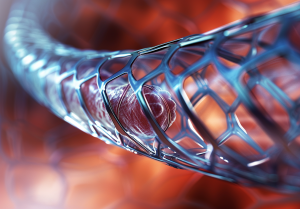

Cardiovascular Stents use special coatings to keep arteries open. These coatings release medication gradually to prevent the arteries from becoming blocked again, which lowers the need for additional surgeries. By delivering treatment directly where it is needed, these coatings make the procedure more effective and reduce risks for patients.

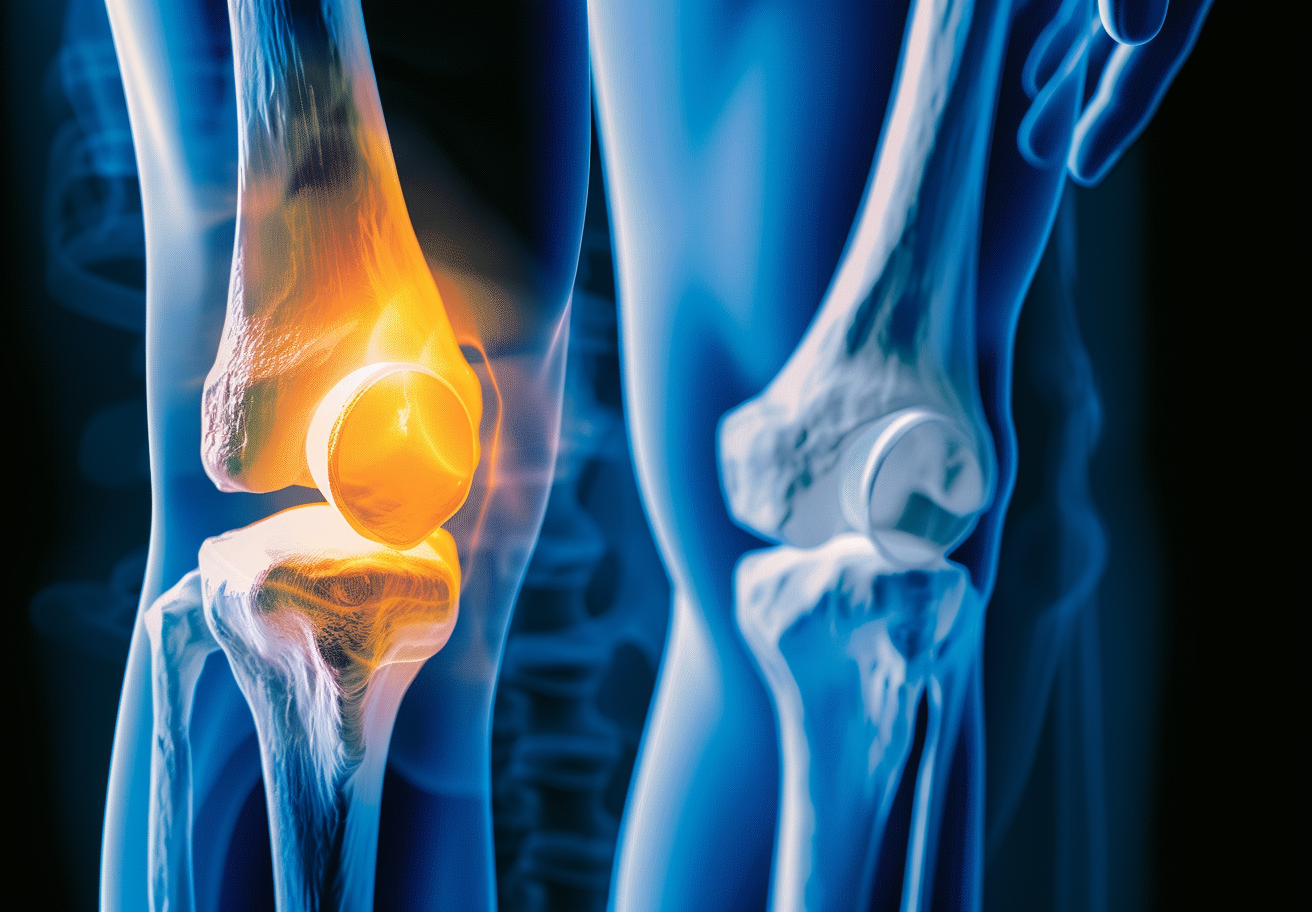

Hip and Knee Implants use ceramic coatings to help them attach to bone. This attachment is crucial because it ensures that the implant remains stable and secure over time. A good bond with the bone allows the implant to move more naturally with the body, reducing the chances of loosening or shifting. This leads to better outcomes for patients and reduces the likelihood of needing future surgeries.

Dental Implants benefit from coatings made of titanium, which resist corrosion and promote bone growth. This is particularly important in the mouth, where conditions can be harsh, and implants need to be durable. By encouraging bone growth around the implant, these coatings help create a strong foundation for artificial teeth.

Neural Stimulators and Sensors often have coatings that prevent infections. These devices interact with sensitive nervous tissues, so keeping them free from bacteria is vital. The coatings reduce the risk of infections, which can have serious consequences for patients. A coating that prevents infections can make a big difference in patient care.

6. Future Directions

Looking to the future, there are several promising directions for biocompatible coatings. New materials, such as graphene and diamond coatings, offer unique benefits. Graphene, known for its strength and ability to conduct electricity, could improve the performance of implants in the heart or brain. Diamond coatings, which are incredibly hard and resistant to wear, could help joint replacements or dental implants last much longer.

Personalized medicine is also gaining attention. Coatings can be customized to suit each patient’s specific needs, which can help reduce complications and improve results. This approach could lead to better patient care by making treatments more targeted and effective.

Artificial intelligence (AI) and machine learning are beginning to assist in the design of these coatings. AI can predict how different materials will perform inside the body, which speeds up research and development. For example, AI can simulate how a new coating will interact with tissues or respond to diseases, allowing researchers to improve the coating before testing it in real patients.

7. Conclusion

Biocompatible coatings are playing an increasingly important role in medical implants and devices. They help make implants safer, more durable, and more effective. As new methods and materials continue to be developed, these coatings will become even more essential in healthcare. For those involved in this field—whether manufacturers, researchers, or regulators—keeping up with these advancements and investing in further research will be crucial.

If you have any questions or need help purchasing biocompatible coating materials, please contact our team.