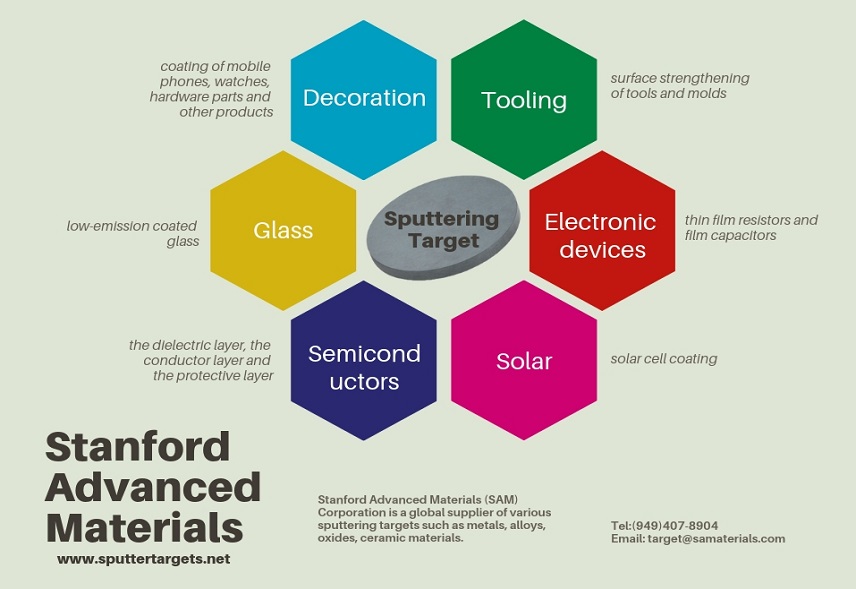

The sputtering target refers to the sputtering source that is deposited on a substrate to form various functional films under appropriate process conditions. Sputtering targets are widely used in many fields such as decoration, tooling, glass, electronic devices, semiconductors, and solar cells.

Sputtering targets required in different fields vary. They can be classified into pure metal target, alloy target, oxide targets, silicide targets, etc. according to the composition (SAM’s Sputtering Target Catogories.pdf); they can also be classified into powder targets, smelting targets and a spray targets according to the production method; and they are divided into planar targets and rotating targets according to their shapes. The followings are their application fields.

Sputtering Film for Decorative Coating

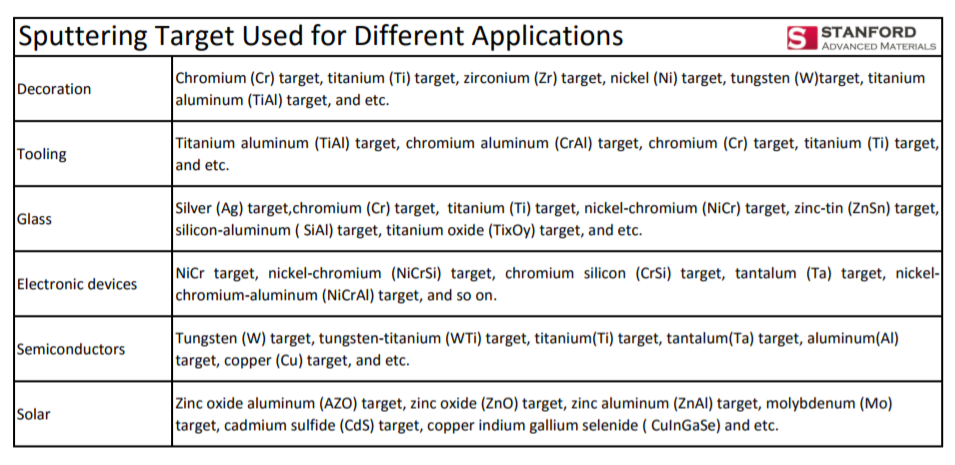

Decorative coating mainly refers to the surface coating of mobile phones, watches, glasses, sanitary ware, hardware parts, and other products. It can not only beautify the color of the substrate but also has the function of improving wear resistance and corrosion resistance. The continuous improvement of people’s living standards requires more and more daily necessities for decorative coating, so the demand for decorative coating targets is increasing. The main types of sputtering targets for decorative coating are chromium (Cr) target, titanium (Ti) target, zirconium (Zr), nickel (Ni), tungsten (W), titanium aluminum (TiAl), etc.

Sputtering Film for Tool Coating

Tooling coating is mainly used for surface strengthening of tools and molds, which can significantly improve the service life of tools and molds and the quality of processed parts. In recent years, driven by the development of the aerospace and automotive industries, the technical level and production efficiency of the global manufacturing industry have made great progress, and the demand for high-performance tools and molds is increasing. At present, the global tool and die coating market is mainly in Europe, America and Japan. According to statistics, the proportion of coatings for machining tools in developed countries has exceeded 90%. The main types of targets for tooling coating are TiAl target, chromium aluminum (CrAl) target, Cr target, Ti target, and the like.

Sputtering Film for Glass Coating

The application of the target on the glass is mainly to produce low-emission coated glass. By magnetron sputtering, we can obtain a multi-layer film on the glass, which can achieve the functions of energy saving, light control, and decoration. Low-emission coated glass is also known as energy-saving glass. In recent years, with the increase in energy conservation and emission reduction and improvement in people’s quality of life, traditional architectural glass is gradually being replaced by energy-saving glass. It is in this market demand that almost all large glass deep-processing companies are rapidly increasing the coated glass production line. Correspondingly, the demand for sputtering targets is rapidly increasing. The main targets used for glass coating are the silver (Ag) target, Cr target, Ti target, nickel-chromium (NiCr) target, zinc-tin (ZnSn) target, silicon-aluminum ( SiAl) target, titanium oxide (TixOy) target, etc.

In addition to producing low-emissivity glass, another important application of the target is to prepare automotive rearview mirrors, mainly using chromium targets, aluminum targets, titanium oxide targets, and the like. With the increasing requirements for automotive rearview mirrors, many companies have switched from the original aluminizing process to the vacuum-sputtering chrome process.

Sputtering Film for Electronic Device Coating

Electronic device coating is mainly used for thin-film resistors and film capacitors. The thin film resistor can provide a resistance of 10 to 1000 MΩ, the temperature coefficient of resistance is small and the stability is good. The target used for making thin-film resistor includes the NiCr target, nickel-chromium (NiCrSi) target, chromium silicon (CrSi) target, tantalum (Ta) target, nickel-chromium-aluminum (NiCrAl) target, and so on.

Sputtering Film for Semiconductor Coating

The rapid development of information technology requires higher integration of integrated circuits and smaller size of unit devices in circuits. The size of components ranges from millimeters to micrometers to nanometers. Each unit is internally composed of a substrate, an insulating layer, a dielectric layer, a conductor layer, and a protective layer. Among them, the dielectric layer, the conductor layer, and even the protective layer require film coating. Therefore, the sputtering target is one of the core materials for preparing an integrated circuit. The main targets for semiconductor coating are tungsten (W) target, tungsten-titanium (WTi) target, titanium(Ti), tantalum(Ta) target, aluminum(Al) target, copper (Cu) target, etc. Semiconductor coating requires high target purity, generally 4N or more, so the target price for semiconductor coating is higher.

Sputtering Film for Solar Cell Coating

With the decline of traditional fossil fuel energy, the world has turned its attention to renewable energy. Solar energy has become the focus of attention with its unique advantages, converting solar energy into heat and electricity. The light-to-electrical conversion is accomplished by the solar cell that directly converts light energy into electrical energy through the photoelectric effect.

At present, solar cells have been developed for the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, and the third generation is thin-film solar cells (represented by copper indium gallium selenide [CIGS]). The sputter coating process is preferred in solar cell coating.

Further Reading: Development of Solar Panel Materials

The rise of the global low-carbon economy has provided broad prospects for the development of new energy and new materials. The target suppliers of solar cell coatings around the world have made solar cell coating targets an important research and development product, and solar cell coatings are growing in an explosive manner. The main targets for solar cell coating are the zinc oxide aluminum (AZO) target, zinc oxide (ZnO) target, zinc aluminum (ZnAl) target, molybdenum (Mo) target, cadmium sulfide (CdS) target, copper indium gallium selenide ( CuInGaSe) and etc.

We have summarized the sputtering targets used in the six mentioned fields. (Sputtering Target Used for Different Applications.pdf)

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets such as metals, alloys, oxides, and ceramic materials. Please visit https://www.sputtertargets.net/ for more information.