1. Introduction

Transparent Conductive Oxides (TCOs) are a unique class of materials that combine two essential properties: optical transparency and electrical conductivity. These characteristics make TCOs indispensable in various technological applications, ranging from touch screens and flat-panel displays to solar cells and smart windows. The ability to conduct electricity while allowing light to pass through them makes TCOs a key component in devices that require visibility and electrical functionality.

2. Composition and Materials

TCOs are typically composed of metal oxides, with the most common materials being Indium Tin Oxide (ITO), Zinc Oxide (ZnO), and Tin Oxide (SnO2). Each of these materials has unique properties and applications, which we will explore in detail.

Indium Tin Oxide (ITO)

- Composition: ITO is a mixture of indium oxide (In2O3) and tin oxide (SnO2), usually with a ratio of about 90% indium oxide to 10% tin oxide.

- Properties: ITO is well-known for its excellent electrical conductivity and high optical transparency. It is also chemically stable and has good adhesion to various substrates.

- Applications: ITO is widely used in the manufacture of liquid crystal displays (LCDs), organic light-emitting diodes (OLEDs), and touch screens. Its ability to form a transparent yet conductive layer makes it ideal for these applications.

Zinc Oxide (ZnO)

- Composition: Pure zinc oxide can be doped with aluminum to create Aluminum-doped Zinc Oxide (AZO), which enhances its conductive properties.

- Properties: ZnO is known for its good optical transparency and moderate electrical conductivity. When doped with aluminum, its conductivity improves significantly.

- Applications: ZnO and AZO are used as transparent electrodes in solar cells, flat-panel displays, and some types of sensors. They are considered a cost-effective alternative to ITO due to the abundance of zinc.

Tin Oxide (SnO2)

- Composition: Tin oxide can be doped with fluorine to produce Fluorine-doped Tin Oxide (FTO), which improves its conductive properties.

- Properties: FTO is highly transparent in the visible spectrum and has good electrical conductivity. It is also chemically robust, making it suitable for various environmental conditions.

- Applications: FTO is commonly used in solar cells, especially in thin-film photovoltaics, as well as in smart windows that can change transparency in response to electrical signals.

3. Properties of TCOs

Transparent Conductive Oxides (TCOs) possess a unique combination of properties that make them essential for various technological applications. These properties include optical transparency, electrical conductivity, and chemical and mechanical stability.

Optical Transparency

TCOs are highly transparent in the visible spectrum, typically with transmittance rates exceeding 80%. This high level of transparency is crucial for applications where visibility is essential, such as in displays and solar cells. The transparency of TCOs allows them to transmit light without significant absorption or reflection, making them ideal for use as transparent electrodes.

Electrical Conductivity

Despite their transparency, TCOs are also good electrical conductors. This property arises from the presence of free carriers (electrons or holes) in the material, which can move under the influence of an electric field. The conductivity of TCOs is generally lower than that of metals but is sufficient for applications requiring both transparency and electrical functionality. The electrical properties can be fine-tuned by doping the TCO material with specific elements to increase the carrier concentration.

Chemical and Mechanical Stability

TCOs are chemically stable under various environmental conditions, including exposure to air and moisture. This stability ensures that TCO films maintain their properties over time, making them durable for long-term use. Additionally, TCOs exhibit good mechanical stability, meaning they can withstand physical stresses without significant degradation. This robustness is important for applications in flexible electronics and other areas where mechanical integrity is essential.

4. Deposition Methods for TCO Films

TCOs are typically applied as thin films on substrates using various deposition techniques. The choice of deposition method affects the film’s quality, uniformity, and suitability for specific applications.

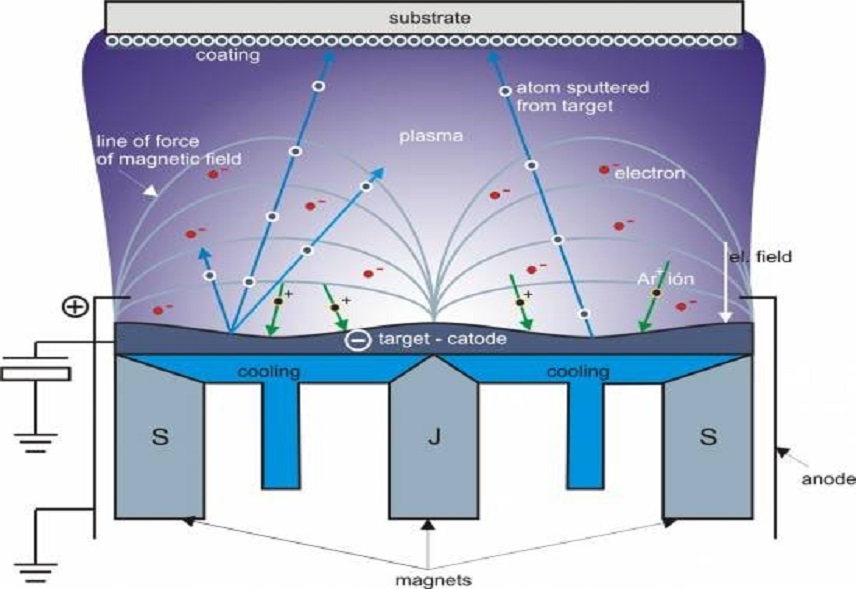

4.1 Sputtering

Process: Sputtering involves bombarding a target material (composed of the desired TCO) with high-energy ions. These ions displace atoms from the target, which then deposit onto the substrate to form a thin film.

Types:

- DC Sputtering: Uses direct current to create the plasma for ion bombardment, best suited for conductive targets.

- RF Sputtering: Utilizes radio frequency, allowing for the sputtering of insulating materials.

- Magnetron Sputtering: Employs a magnetic field to increase ionization efficiency, improving deposition rates and film quality.

Advantages and Disadvantages:

- Advantages: High uniformity, good control over film thickness and composition, suitable for large-area coatings.

- Disadvantages: Requires complex equipment, can be costly, and some materials might have low sputtering yield.

4.2 Evaporation

Thermal Evaporation: Material is heated in a vacuum chamber until it evaporates. The vapor then condenses on the substrate, forming a thin film. This method is simple and cost-effective but may produce less uniform films.

Electron Beam Evaporation: An electron beam heats the material, providing better control and higher purity films compared to thermal evaporation. Suitable for high-melting-point materials.

Further Reading: Electron Beam Evaporation VS Thermal Evaporation

Advantages: Simple setup, can achieve high-purity films.

Disadvantages: May result in less uniform films, and some materials may not evaporate efficiently.

4.3 Chemical Vapor Deposition (CVD)

Process: In Chemical Vapor Deposition (CVD), gaseous precursors react chemically on the substrate surface to form a solid film. Variants like Plasma-Enhanced CVD (PECVD) and Metal-Organic CVD (MOCVD) are used for different applications.

Advantages: Produces highly uniform films, suitable for complex geometries, and allows for precise control over film properties.

Disadvantages: Requires sophisticated equipment and handling of hazardous chemicals.

4.4 Pulsed Laser Deposition (PLD)

Process: A high-power pulsed laser beam ablates material from a target, which then deposits as a thin film on the substrate.

Advantages: Allows precise control over film thickness and composition, can deposit a wide range of materials.

Disadvantages: Limited scalability and requires high-energy lasers.

5. Applications of TCOs

Transparent Conductive Oxides (TCOs) are integral to many advanced technologies due to their unique properties. Here are some key applications:

5.1 Displays

TCOs are widely used in various types of displays, including Liquid Crystal Displays (LCDs), Organic Light-Emitting Diodes (OLEDs), and touch screens. In these applications, TCO films serve as transparent electrodes, allowing the display to emit light while maintaining electrical conductivity.

- LCDs: TCOs like ITO are used as transparent electrodes to control the liquid crystals in each pixel.

- OLEDs: The transparency of TCOs allows light emission through the electrode layer, enhancing display brightness and color purity.

- Touch Screens: TCO films enable touch sensitivity by serving as conductive layers that detect touch input.

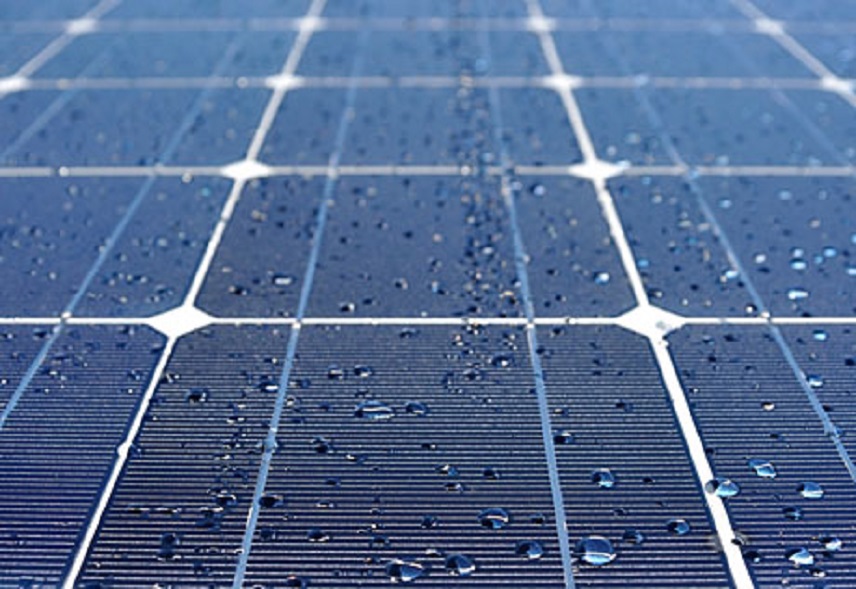

5.2 Photovoltaics

In solar cells, TCOs function as transparent front electrodes that allow sunlight to pass through and generate electrical current. They are essential in both traditional silicon-based solar cells and thin-film solar cells.

- Silicon-based Solar Cells: TCOs are used as the top contact layer to collect and transport electrons generated by the absorbed sunlight.

- Thin-Film Solar Cells: Materials like FTO are used to enhance light absorption efficiency while maintaining electrical conductivity.

5.3 Smart Windows

Smart windows use TCOs to adjust their transparency in response to electrical signals. This technology is used in energy-efficient buildings to control light and heat entry, reducing the need for artificial lighting and air conditioning.

- Electrochromic Windows: TCOs are applied as electrodes in electrochromic devices that change color or transparency when voltage is applied.

- Benefits: Improved energy efficiency, comfort, and privacy.

5.4 LEDs and Lighting

TCOs are used in light-emitting diodes (LEDs) and other lighting applications to improve efficiency and performance. They serve as transparent contacts that allow light to be emitted while maintaining electrical pathways.

- High Brightness LEDs: TCOs like ITO are used to enhance light output and efficiency.

- Organic LEDs (OLEDs): TCOs enable the development of flexible and transparent lighting solutions.

5.5 Sensors

TCOs are used in various types of sensors, including optical sensors, gas sensors, and biosensors. Their transparency and conductivity make them suitable for applications where visibility and electrical response are crucial.

- Optical Sensors: TCOs are used in devices that detect light intensity or color changes.

- Gas Sensors: TCO films can detect changes in gas concentration by measuring changes in electrical resistance.

- Biosensors: TCOs provide a conductive platform for the detection of biological molecules.

6. Conclusion

Transparent Conductive Oxides (TCOs) play a vital role in modern technology, providing the essential properties of transparency and conductivity required for a wide range of applications. From displays and solar cells to smart windows and sensors, TCOs enable the development of advanced devices that are integral to our daily lives. Ongoing research and innovation continue to push the boundaries of TCO technology, promising exciting advancements in the future.