Powder metallurgy is an important metal-forming procedure used in manufacturing essential materials like cutting tools, bearing parts, magnets, etc. Contributing to the automation of the industrial sector, powder metallurgy has continued to attract manufacturers who are looking to lower the cost of manufacturing through forging and machining. This post walks you through the meaning of powder metallurgy, how it is developed, its advantages, and its applications.

What is Powder Metallurgy?

As the name implies, powder metallurgy is an advanced metal processing technique that uses metal powder as its raw material, then compacts the metal powder into a solid material of the desired shape. Sometimes, a small amount of non-metal powder is added to the powder.

Generally, powder metallurgy is concerned with the use of metal powder to manufacture materials or products through mixing, forming, pressing, sintering, and further processing that may be necessary to achieve the desired product properties. Powder metallurgy can be used for the mass production of structural parts with complex shapes and high structural integrity at relatively lower costs without the need for further cutting or processing. For instance, this technique is the main technology used for the mass production of bearing self-lubricating parts at a lower cost. Powder metallurgy is also an important method to make titanium sputtering targets from metal titanium.

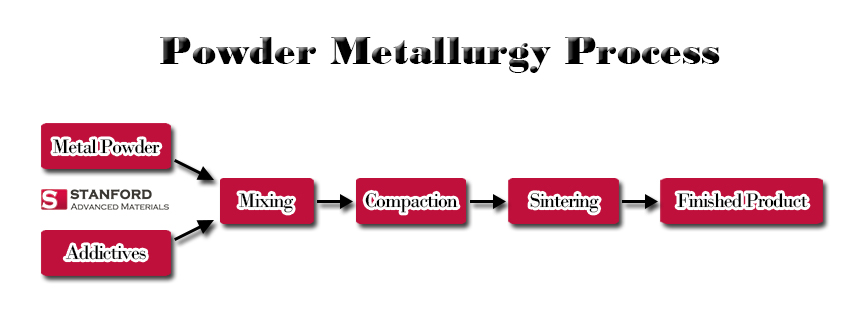

How is Powder Metallurgy Processed?

The powder metallurgy fabrication technique involves the three major processing stages shown below:

1. Production of Metal Powder

In this first stage, the metal powder raw material is produced. Usually, most of the powder used in the production process is manufactured using either water atomization or the sponge iron process. The non-ferrous metal powder materials used can be produced through several other methods.

2. Compaction and Shaping of the Powder

The powder is mixed and then formed into a compact. This may often involve the addition of alloying components in powder form or the introduction of a pressing lubricant. The compacting and shaping process typically involves pressing in a rigid toolset, which comprises a die, punches, and, sometimes, core rods. The powder finally consolidated and fused into a solid metal component under high temperature and pressure.

3. Sintering of the Compact to Enhance Integrity and Strength

At this stage in the compacting process, the compact metal powder is heated, usually to a temperature that is just below the melting point of the major material in the compact. The sintering temperature is ideally protective, but it may also form a liquid phase. This is known as liquid phase sintering. This process helps to strengthen the desired metal shape and enhance its integrity.

Usually, in metal processing, final finishing is required after the sintering process, but in the case of powder metallurgy, the metal gets compacted to a final desired shape. Therefore, there is no need for any further machining of the final product.

Advantages of Powder Metallurgy

Mass production at a reduced cost: Product cost-effectiveness is the most significant reason for choosing powder metallurgy over other methods. Compared to other production techniques, powder metallurgy is the preferred choice when it comes to lower energy consumption, higher material utilization, and reduced number of process steps.

Processing of special materials: The powder metallurgy technique can be used to manufacture special materials, such as refractory metals, compounds, pseudo-alloys, and porous materials.

Save metal and reduce costs: Powder metallurgy pressed the final product to a desired size and shape, eliminating the need for further mechanical processing is required. The typical loss of metal in metallic processing techniques is reduced to about 1-5%, whereas traditional metal processing methods typically consume up to 80% of the metal.

Production of high-purity materials: Powder metallurgy does not melt the material during the production process, a technique that prevents the penetration of impurities into the material. Also, the sintering is performed in a vacuum and protective atmosphere, ensuring that only high-purity material is produced.

Accurate material distribution: Another advantage of the powder metallurgy method is that it ensures accurate material proportioning in terms of the uniformity and composition of the components.

Applications of Powder Metallurgy

Modern technology, as we know it, isn’t complete without powder metallurgy products due to its wide application in various fields. Here are some applications of powder metallurgy:

- Production of porous products, such as bearings and filters.

- Production of tungsten carbide, gauges, wire drawing dies, wire guides, stamping and blanking tools, hammers, etc.

- Powder metallurgy is used to produce various machine parts from tungsten powder. It also produces heat and wear-resistant cutting tools from tungsten carbide powders.

- Powder metallurgy also produces essential refractory parts made from tungsten, tantalum, and molybdenum, commonly used in electric bulbs, radio valves, oscillator valves, X-ray tubes, etc.

- Due to its self-lubricating property, powder metallurgy components are used widely in producing automobile parts bearings and bushes.

- Powder metallurgy makes products with complex shapes, which require considerable machining when made using other metal manufacturing processes.

- Includes the production of components like electrical contacts, crankshaft drives, piston rings, rocker shaft brackets, etc., that are used in automotive part assembly.

Other Metal Manufacturing Process

Powder metallurgy is just one of the several metal manufacturing processes, which also include metal casting, turning, drilling, milling, shaping, planing, broaching, machining, and sawing.

Conclusion

Powder metallurgy is an impressive metal processing technique that uses metal powder as raw material, then compacts the metal powder into a solid material of the desired shape. This process saves manufacturers from metal waste, improves the effectiveness of the metal production process and the quality of the final product, and is known to be the most cost-effective option. For more information about metal manufacturing, please visit https://www.sputtertargets.net/.