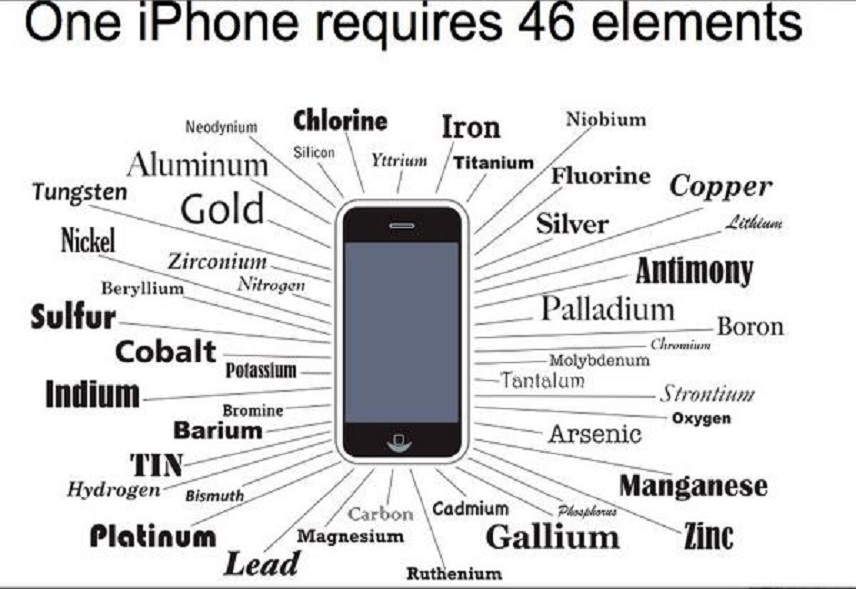

Metal elements have many applications in mobile phones. And today we tend to mention two important ones–molybdenum and titanium. The main use of tantalum materials in electronic products comes in the creation of the tantalum capacitor; and the main use of molybdenum in mobile phones mainly related to the liquid crystal display coating: using magnetron sputtering to sputter metal molybdenum from the molybdenum target onto the surface of a liquid crystal display.

Tantalum

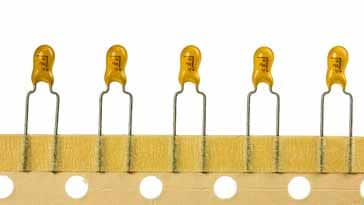

Tantalum could be a vital component within the industry. And it’s widely used in every kind of electronic devices, such as phones and computers. Tantalum plays its role in the electronic industry mainly by the creation of the tantalum capacitor. Tantalum capacitors have their distinctive advantages over other capacitors. They do not use electrolytes like normal electrolytic capacitors, enabling them ideal for operation at high temperatures. Solid tantalum capacitors have wonderful electronic properties, wide operating temperature range, varied forms, and excellent volumetrical potency.

In addition to capacitors, tantalum is also used as wave filters in mobile phones to realize high audio property, since electronic signal wave dampening can provide clearer and crisper audio and video output.

A mobile phone has average forty milligrams of titanium inside. Well, compared with the overall weight of a phone, it’s not an enormous variety. However, this forty milligrams tantalum is irreplaceable. Thanks to the massive demand for mobile phones, the demand for tantalum has conjointly multiplied. Believe it or not, 50% of tantalum is consumed every year in the electronics industry.

Molybdenum

Molybdenum has a high melting point, high electrical physical phenomenon, low specific resistance, smart corrosion resistance, and smart environmental protection. Therefore, it’s wide employed in the electronics industry, mainly for flat panel displays, electrodes of skinny film star cells, and barrier materials for semiconductors. Coating the phone screen with molybdenum sputtering target will greatly improve the brightness, contrast, color, and lifetime of the screen.

In the process of film coating, the quality of the sputtering target has a great influence on the quality of the produced film. Stanford Advanced Materials (SAM) specializes in producing high purity molybdenum sputtering targets with the highest possible density and smallest possible average grain sizes for use in the PVD, CVD, APS and VPS coating processes. We have both of planar molybdenum target and rotatory molybdenum target. Please visit for https://www.sputtertargets.net/ more information.