PVD(Physical Vapor Deposition) coating, a physical terminology which is seemingly difficult to understand, actually is connected closely to our daily lives. Your beautiful jewelry, expensive camera and sharp knives may all use PVD coating. If you want to know more about PVD coating, just continue to read.

What is PVD coating?

PVD Coating, or Physical Vapor Deposition, refers to a variety of vacuum deposition techniques where solid metal is vaporized to produce thin films and coating. More specifically, in a high vacuum environment, the solid metal is first changed to a vapor state and then deposited on other materials in a solid state again. PVD coating has many advantages such as good durability, wide application and less pollution, so it has been more and more used for multiple purposes nowadays.

Decorative Coating

PVD Coating is widely used for decorative purpose due to its beautiful and various metallic colors. In watch industry, TiN is used to coat gold color and Cr2N is used to coat silver color. PVD coating also provides other kinds of metallic colors such as rose gold, smoke grey, purple bronze and so on. In addition to watches, some cellphone-parts, jewelries, toys, buttons also use PVD coating for decorative purpose.

Optical Coating

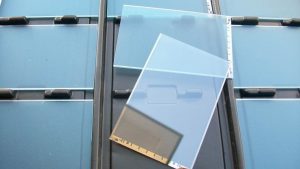

PVD coating application in optical coating includes anti-reflection coating in cameras, high-reflection coating in solar receiver, optical storage in discs and so on.

PVD coating application in optical coating includes anti-reflection coating in cameras, high-reflection coating in solar receiver, optical storage in discs and so on.

Protective Coating

PVD coatings are harder and more resistant to corrosion, therefore it can be used for protective purpose. For example, TiN, TiC and c-BN are frequently used as hard film in cutting and abrasive tools. Corrosion protection film, lubricant film and thermal protective film are also included.

Electrical Coating

PVD Coating can be used to produce conductive materials and dielectric thin film materials in semiconductor devices and integrated circuits, superconducting thin film and ITO Film.

Stanford Advanced Materials (SAM) Corporation is a global sputtering target manufacturer established in 1994. For more information, please visit https://www.sputtertargets.net/.