As we all know, the technological development trend of the target material is closely related to the development trend of the film technology in the downstream application industry. With the technology improvement of the film products or components of the application industry, the target technology should also be changed. For example, Ic manufacturers, which have been devoted to the development of low resistivity copper wiring in recent years, are expected to replace the original aluminum film in the next few years, so that the development of copper targets and their barrier targets will be of no delay.

In recent years, FPD has greatly replaced the computer display and television market, which was the main cathode ray tube (CRT), and will also greatly increase the technology and market demand of indium target. In addition, in storage technology, high density, large capacity hard disk, high density erasable CD-ROM demand continues to increase, which results in the demand for the target in the application industry. We will introduce the following main application field of the target, and the trend of the development of the field of the target material.ITO

The field of Microelectronics

In all applications, the quality demand of sputtering target in the semiconductor industry is the highest. Now 12-inch silicon wafers have been produced. And the width of the interconnection is on the decrease. Requirements of the target wafer maker is a large size, high purity, low segregation and fine grain microstructure of the target, which requires the better manufacturing. The target of crystalline particle diameter and uniformity has been considered as the key factors affecting the deposition rate.

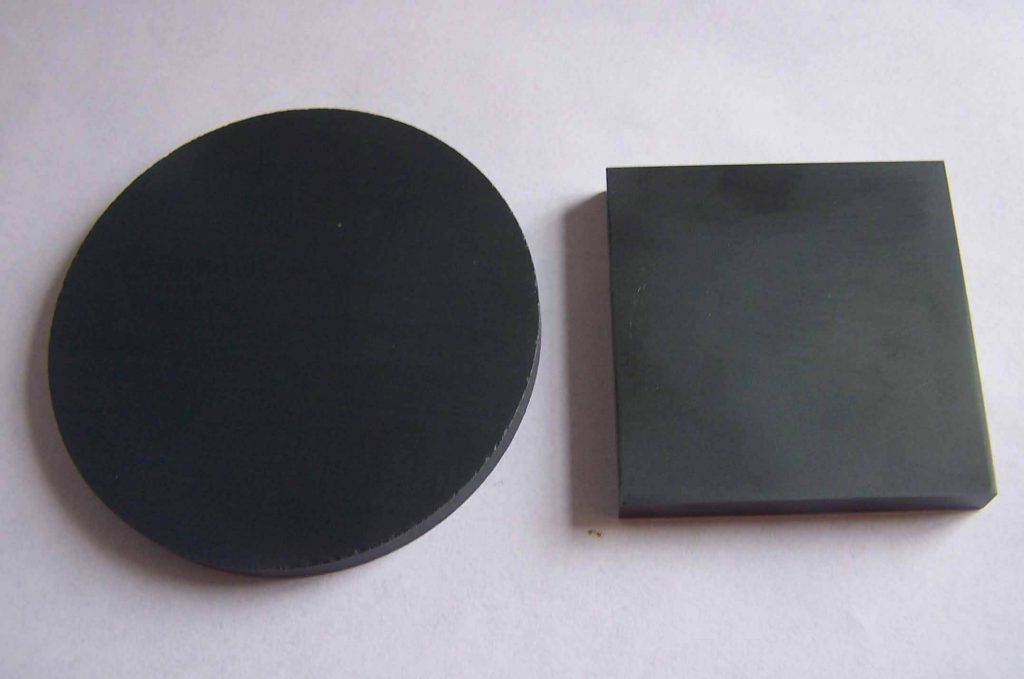

ITO target is widely used in the flat panel display, the main target is widely used in the semiconductor. The development of science and technology, the electronics industry to occupy a large share of the market, directly affects people’s work and life. The ITO target has a high-performance advantage, and has a high heat shock resistance. It will not damage the equipment in use, and its purity is especially high. At present, a lot of electronic products in the market use flat display, liquid crystal computer and LCD TV into thousands of households. The products of liquid crystal are high in appearance and in texture, and can reduce energy consumption.

ITO target is widely applied to the electronic field, because the electronic field for the material requirement is relatively high. It plays a certain role in the development of the electronic industry. At the same time, the target can prolong the life of the electronic products, and the quality of the electronic products is in line with the testing standard.

Stanford Advanced Materials (SAM) Corporation is a global sputtering target manufacturer established in 1994. For more information, please visit https://www.sputtertargets.net/.