In recent years, with the rapid development of coating technology, the demand for sputtering targets has increased rapidly. Then some people who are unfamiliar with sputtering targets may doubt: What are the applications of sputtering targets? The following is a detailed summary by SAM Sputter Targets.

Decorative coating

Decorative coating mainly refers to the surface coating of mobile phones, watches, glasses, sanitary ware, hardware parts and other products. Decorative coating not only plays a role in beautification, but also has functions such as wear resistance and corrosion resistance. With the continuous improvement of people’s living standards, the demand for decorative coatings for decorative coatings is increasing.

The main types of targets used for decorative coating are: chromium (Cr) sputtering target, titanium (Ti) sputtering target, zirconium (Zr) sputtering target, nickel (Ni) sputtering target, tungsten (W) sputtering target, titanium aluminum (TiAl) sputtering target, stainless steel target, etc.

Glass coating

Low-emission coated glass, also known as energy-saving glass, has recently replaced traditional architectural glass with the increasing demand of energy-saving and consumer quality. In this case, almost all large glass processing companies are rapidly increasing the glass coating line. Correspondingly, the demand for sputtering targets has also increased rapidly.

The main types of targets used for glass coating are: silver (Ag) sputtering target, chromium (Cr) sputtering target, titanium (Ti) sputtering target, nickel-chromium (NiCr) sputtering target, zinc-tin (ZnSn) sputtering target, aluminum-silicon (AlSi) sputtering target, titanium oxide (TixOy) sputtering target, etc.

Another important application of the target on glass is the preparation of automotive rearview mirrors, mainly using chromium (Cr) sputtering target, aluminum (Al) sputtering targets, titanium (Ti) sputtering target, etc. With the increasing requirements of automotive rearview mirrors, many companies have switched from the original aluminizing process to the vacuum sputtering chrome process.

Tool coating

Tool coating is mainly used for surface strengthening of tools and molds, which can significantly improve the service life of tools and molds and the quality of processed parts. In recent years, driven by the development of the aerospace and automotive industries, the technical level and production efficiency of the global manufacturing industry have made great progress, and the demand for high-performance tools and molds is increasing.

The main types of targets used for tool coating are: titanium aluminum (TiAl) sputtering target, aluminum chromium (AlCr) sputtering target, chromium (Cr) sputtering target, titanium (Ti) sputtering target,etc.

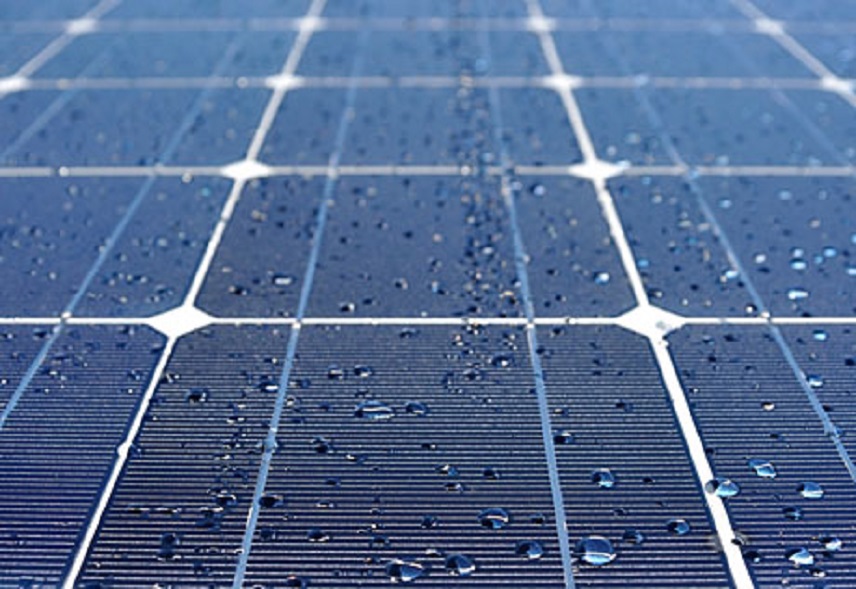

Solar cell coating

With the decline of traditional fossil fuel energy, the world has turned its attention to renewable energy. At present, solar cells have developed to the third generation. The first generation is monocrystalline silicon solar cells, the second generation is amorphous silicon and polycrystalline silicon solar cells, the third generation is thin film solar cells (represented by copper indium gallium selenide CIGS), and the sputter coating process is the preferred preparation method.

The main types of targets used for Solar cell coating are: Aluminum zinc oxide (AlZO) sputtering target, zinc oxide (ZnO) sputtering target, zinc aluminum (ZnAl) sputtering target, molybdenum (Mo) sputtering target, cadmium sulfide (CdS) sputtering target, copper indium gallium selenide (CIGS) sputtering target, etc.

Stanford Advanced Materials (SAM) Corporation is a global supplier of various sputtering targets such as metals, alloys, oxides, ceramic materials. We provide high purity of sputtering targets and evaporation materials, as well as target bonding services, and all of the sputtering targets talked above can be found in our website. If you are interested, please https://www.sputtertargets.net/ for more information.