| Catalog No. | DP1233 |

|---|---|

| Purity | ≥99.5 % |

| Shape | Spherical powder |

| Particle Size | 0-15,15-53,45-105,75-150 μm |

| Oxygen content | 800-1500ppm |

Spherical titanium powder for 3D printing now can be supplied by Stanford Advanced Materials (SAM). Sizes of our titanium powder can be customized upon your requests.

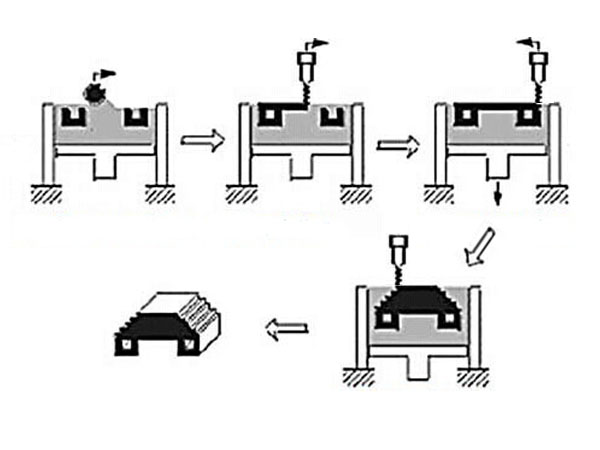

The method of 3D printing titanium, also known as direct metal laser sintering (DMLS), is an additive metal fabrication process. This process builds on the basic principles of 3D printing through the application of metallic materials for direct utility in just about any field that would need the uses of such immediately developed technology.

A 3D printing titanium model is printed in spherical titanium powder that is sintered together by a laser to produce end-use parts. 3D printed unpolished titanium model is a little grayer and more matte with a slightly rougher and less defined surface. However, 3D printing can produce a more complicated titanium model which traditional techniques could hardly achieve.

| Grade | mainly composition (wt. %) | Impurities Max. | ||||||

| Ti | Fe | C | N | H | O | Other elements | ||

| Single | Sum | |||||||

| TA1 | balance | 0.2 | 0.08 | 0.03 | 0.015 | 0.18 | 0.1 | 0.4 |

| TA2 | balance | 0.3 | 0.08 | 0.03 | 0.015 | 0.25 | 0.1 | 0.4 |

| TA3 | balance | 0.3 | 0.08 | 0.05 | 0.015 | 0.35 | 0.1 | 0.4 |

Our 3D printing spherical titanium powder is clearly tagged and labeled externally to ensure efficient identification and quality control. Great care is taken to avoid any damage which might be caused during storage or transportation.

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

Not much to say about this - it was packed well and is as described. Worked well and would buy again.