| Catalog No. | DP1309 |

|---|---|

| Purity | 99.5% |

| Chemical Formula | Ni |

| Shape | Spherical Powder |

| Particle Size | 50nm,500nm,1um or Customized |

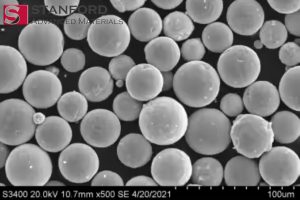

Stanford Advanced Materials (SAM) provides spherical nickel powder suitable for 3D Printing applications. As the additive manufacturing industry advances, so will our additive manufacturing powder product offerings.

Our Spherical Nickel Powder is a premium-grade material specifically designed for additive manufacturing, electronics, and industrial applications. This powder is characterized by high purity (≥99.9%), excellent sphericity, and uniform particle size distribution, making it the preferred choice for industries requiring precision, efficiency, and reliability.

Our spherical nickel powder is widely recognized for its high performance in 3D printing and other advanced manufacturing processes.

| Item | Particle Size | Purity(%) | Specific area (m2/g) | Bulk density (g/cm3) | Density (g/cm3) | Form | Color |

| ME28S -50nm | 50nm | 100.5 | 12 | 0.74 | 8.9 | Spherical | Black |

| ME28S -500nm | 500nm | 100.5 | 7.4 | 1.12 | 8.9 | Spherical | Black |

| ME28S -1um | 1um | 100.5 | 3 | 1.68 | 8.9 | Spherical | Black |

Our spherical nickel powder excels in a wide range of applications, thanks to its superior properties such as high purity, low porosity, and excellent flowability.

| Application | Description |

|---|---|

| 3D Printing | Ideal for DMLS (Direct Metal Laser Sintering) and other additive manufacturing processes. |

| MLCCs | Used as inner electrodes in ceramic capacitors, ensuring high electrical performance. |

| Conductive Pastes | Enhances conductivity in silver-based pastes for electronics. |

| Welding | Suitable for laser and metal inert gas welding processes. |

| Brazing Alloys | Functions as a high-temperature braze filler material. |

| Nickel Plating | Provides corrosion-resistant and wear-resistant coatings. |

| Catalysts | Acts as a high-efficiency catalyst in various chemical reactions. |

| Battery Materials | Essential for rechargeable batteries and energy storage systems. |

The superior sphericity and uniform size distribution of our nickel powder ensure optimal performance in these applications.

Our spherical nickel powder is produced using the atomization method, ensuring high sphericity, low oxygen content, and controlled microstructure. Key manufacturing benefits include:

To ensure product integrity and ease of use, our Spherical Nickel Powder is securely packaged and clearly labeled. We offer the following packaging options:

Storage Instructions:

Do you have specific requirements for spherical nickel powder? Contact us today to discuss custom particle sizes, packaging, or applications. We are here to help you achieve the best results for your projects.

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

The spherical nickel powder from this supplier has significantly improved the efficiency of our 3D printing process. Highly recommend for advanced manufacturing!

Excellent product quality and great customer support. The uniform particle size distribution was exactly what we needed.