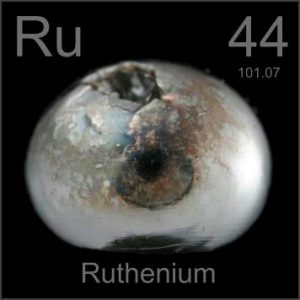

Chemical Formula: Ru

Catalog Number: ST0039

CAS Number: 7440-18-8

Purity: 99.95%

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Ruthenium sputtering target is available in various forms, purities, sizes, and prices. We’re capable of supplying custom sputtering materials per any specs/drawings you provide with us.

Ruthenium, a member of the platinum group metals, is renowned for its hardness, corrosion resistance, and excellent catalytic properties. Our high-purity Ruthenium Sputtering Targets are designed for superior performance in various thin-film deposition processes including Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD), crucial for applications in semiconductor, display technologies, and optical devices.

| Material Type | Ruthenium |

| Symbol | Ru |

| Color/Appearance | Gray |

| Melting Point | 2334 °C |

| Density | 12370 kg/m3 |

| Thermal Conductivity | 1.17 W·m-1·K-1 (25°C) |

| Thermal Expansion | 6.4 µm/(m·K) (25°C) |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets, please inquire for more information.

Ruthenium targets are extensively used due to their high melting point and density, making them ideal for:

We offer custom-made targets tailored to your specific requirements, including various shapes and dimensions. Additionally, Indium Bonding services are provided to ensure the high performance and longevity of your sputtering targets.

Our Ruthenium Sputtering Targets are carefully handled and packaged in a vacuum-sealed barrier to ensure they are delivered in optimal condition. Typical lead times are 2-5 weeks, and each package includes a material safety data sheet (MSDS) and certificate of analysis (COA).

Q1: What purity levels do you offer for Ruthenium Sputtering Targets?

A1: We provide Ruthenium Targets with a purity of up to 99.95%.

Q2: Can Ruthenium Targets be customized in size and shape?

A2: Yes, we offer customization in various dimensions and forms to suit specific equipment and applications.

Q3: What are the bonding options available for Ruthenium Targets?

A3: We offer Indium and Elastomer bonding to ensure optimal performance in your specific setup.

Q4: How is Ruthenium advantageous over other metals in sputtering processes?

A4: Ruthenium provides superior hardness, corrosion resistance, and maintains stability at high temperatures, making it ideal for demanding deposition environments.

Q5: How do you ensure the quality of your Ruthenium Targets?

A5: Each target is rigorously tested and comes with a certificate of analysis to ensure high standards of quality and purity are met.

For more detailed information, pricing, or to discuss your specific requirements, please contact us. Our expert team is ready to provide you with the necessary support and solutions tailored to your unique needs.

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

Bought these and donated them to the local Community College chemistry lab.

Hope they be happy when they are to receive these gift.