Chemical Formula: Mo

Catalog Number: ST0030

CAS Number: 7439-98-7

Purity: >99.9%, 99.95%

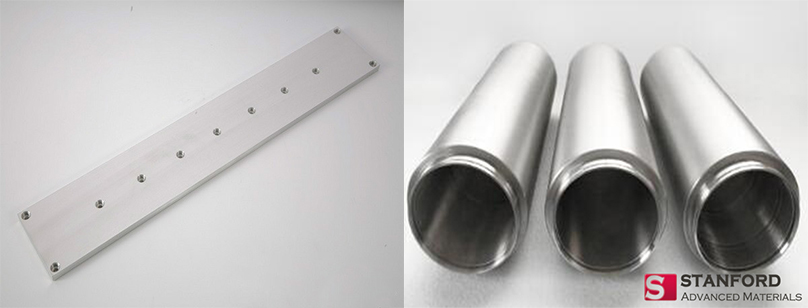

Shape: Discs, Plates, Column Targets, Step Targets, Custom-made

Molybdenum sputtering target is available in various forms, purities, sizes, and prices. Stanford Advanced Materials (SAM) manufacture molybdenum target according to your specifications.

Molybdenum Sputtering Target Safety Data Sheet

Molybdenum Sputtering Target Safety Data Sheet

Molybdenum sputtering target shares properties with its source material, either pure molybdenum or molybdenum alloy. Molybdenum metal is silvery-white and very hard. Its melting point is 2623°C (4753°F), which is only lower than tantalum, osmium, rhenium, tungsten among natural elements. It also has one of the lowest coefficients of thermal expansion among metals in commercial use.

Molybdenum target has a density of almost 100 %. The denser the Mo target is, the better the conductivity of the created layer. SAM specializes in producing high purity sputtering target materials with the highest possible density and smallest possible average grain sizes for use in the PVD, CVD, APS and VPS coating processes. You benefit from a faster process due to higher sputtering speeds.

| Material Type | Molybdenum |

| Symbol | Mo |

| Color/Appearance | Grey, Metallic |

| Melting Point | 2,617 °C |

| Sputter | DC |

| Type of Bond | Indium, Elastomer |

| Comments | Films smooth, hard. Careful degas required. |

| Density | 10280 kg/m3 |

| Available Sizes | Dia.: 1.0″, 2.0″, 3.0″, 4.0″, 5.0″, 6.0″ Thick: 0.125″, 0.250″ |

We also offer other customized shapes and sizes of the sputtering targets, please send us an inquiry for more information.

High-performance molybdenum sputtering materials are used for thin-film coating applications, CD-ROM, decoration, flat panel displays, functional coating as nicely as other optical information storage space industry, glass coating industry like car glass and architectural glass, optical communication, etc.

Our planar molybdenum sputtering targets have high purity & density and uniform microstructure that can be perfectly applied in depositing thin films in TFT displays and other related industries. Both single and multi-piece molybdenum planar targets are available.

Our rotatory molybdenum sputtering targets have a high utilization rate of more than 75% that ensures you make full use of the target materials.

Indium Bonding and Elastomeric Target Bonding Service are available for molybdenum sputtering target. Stanford Advanced Materials is devoted to machining standard backing plates and working together with the Taiwan Bonding Company for providing bonding services. For questions about target bonding materials, methods and services, please click here.

Our molybdenum sputter targets are carefully handled to prevent damage during storage and transportation and to preserve the quality of our products in their original condition.

SAM’s molybdenum sputtering targets are available in various forms, purities, sizes, and prices. We specialize in producing high purity thin film coating materials with the highest possible density and smallest possible average grain sizes for use in semiconductor, chemical vapor deposition (CVD) and physical vapor deposition (PVD) display and optical applications. Please send us an inquiry for the current prices of sputtering targets and other deposition materials that are not listed.

Related Articles:

What Are the Uses of Molybdenum Sputtering Targets?

Why is Molybdenum Target Used in Mammography for Breast Cancer?

Submit your review | |

1 2 3 4 5 | |

Submit Cancel | |

I got exactly what I wanted to receive. Exact size as advertised. There are too many options of sizes. Will buy it again.