A vacuum evaporation film, in an environment of no less than 10-2Pa vacuum, which is heated by resistance heating or electron beam and laser bombardment to heat the evaporated material to a fixed temperature so that the thermal vibration energy of the molecules or atoms in the material exceeds the binding energy of the surface, so that a large number of molecules or atoms are evaporated or sublimated and directly precipitated on the substrate. The ion mud emits coating is a high admonishing motion bombardment using the positive ion produced by gas discharge in the electric field as the target of the cathode, so that the atoms or molecules in the target are escaping and precipitated to the surface of the plated workpiece to form the required film.

The most commonly used method of vacuum evaporation coating is electric bile heating. Its advantages are that the structure of the heating source is simple, the cost is low and the operation is convenient. It is not suitable for the refractory metal and the medium material with high-temperature resistance. Electron beam heating and laser heating can overcome the shortcomings of resistance heating. Electron beam heating is used to directly heat the bombarded material by focusing the electron beam, and the kinetic energy of the electron beam becomes heat energy, which makes the material evaporate. Laser heating is the use of a high-power laser as a heating source, but because of the high cost of high-power laser, it can only be used in a few research laboratories.

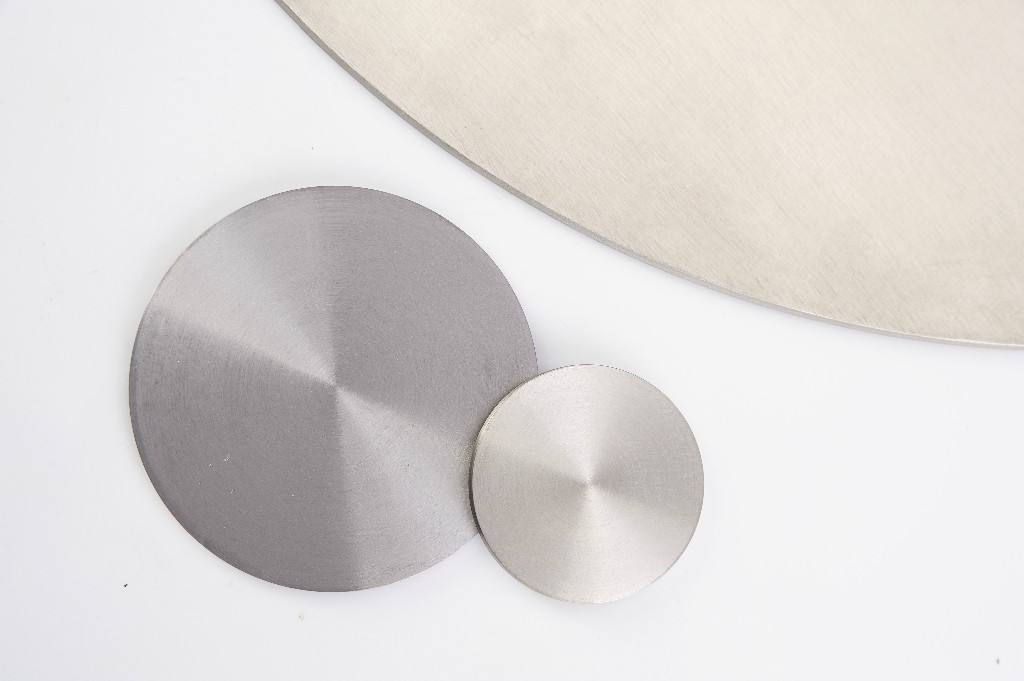

The sputtering technology is different from the vacuum evaporation technology. Sputtering refers to the phenomenon of energetic particles bombarding the surface of a target to cause solid atoms or molecules to emit from the surface. Most of the emitted particles are in an atomic state, often referred to as the jet atom. The sputtering particles used to bombard the sputter target can be electrons, quotient or neutral particles, because the ions are easy to speed up the kinetic energy under the electric field, so most of the ions are used as bombardment particles. The sputtering process is based on glow discharge, that is, sputtering ions originate from the gas discharge. Different sputtering technologies adopt different glow discharge modes. DC Bi pole sputtering is made of DC glow discharge tri-pole sputtering, which uses radio-frequency glow discharge (RF glow discharge) using a hot cathode supported glow discharge (RFD), and magnetron sputtering is a glow discharge controlled by a circular magnetic field.

Compared with vacuum evaporation coating, the sputtering coating has many advantages. If any material can be spattered, especially the elements and compounds with high melting point and low vapor pressure, the adhesion of the sputtering film to the substrate is good, the density of the film is high, the thickness of the film can be controlled and the reproducibility is good. The drawback is that the equipment is more complex and requires a high-pressure device.

In addition, the evaporation method is combined with sputtering, that is, ion plating. The advantage of this method is that there is a very strong adhesion between the film and the substrate, high deposition rate and high density of the film.

Stanford Advanced Materials (SAM) Corporation is a global sputtering target manufacturer established in 1994. For more information, please visit https://www.sputtertargets.net/.