Sputtering target is the key material for vacuum magnetron sputtering (PVD) coating.

Working principle of target material:

The target material is used as the cathode in the PVD system. The free electrons produced by the vacuum system impact the Ar molecule and form the Ar+ cation under the acceleration of the electric field, and the Ar+ cations impact the target (cathode) at a high speed in the electric field, so that the atom or atomic mass on the surface of the target is knocked out in the form of gas state and then deposited into the vacuum cavity. The required coating or nano film is formed on the substrate.

Because it is the target of attack, it is called sputtering target.

Industry for target application:

The industry of magnetron sputtering is widely used, including optical storage (optical disk), magnetic storage (hard disk), flat panel display (LCD, plasma display, OLED, etc.), wear resistance industry (mechanical tools, bearings, engine blades, high grade clocks and so on), electromagnetic protection (EMI), solar cell industry, energy saving Glass (Low-E glass, etc.), crystal oscillator, metal film resistor and so on.

Materials and types of target materials:

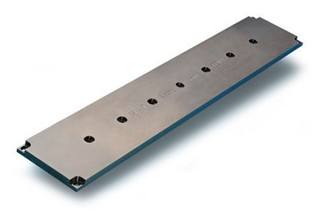

The target is named after its action, and its material is very extensive. All kinds of single metals, alloys and ceramics can be used as targets. For example, Al, Ag, Au, Pt, Cu, SUS, Ni, Ta, NiCr, NiCo and TiAl are can be used as target materials.

The requirement of target is higher than that of the traditional material industry, such as size, flatness, purity, impurity content, density, N/O/C/S, grain size and defect control.

Stanford Advanced Materials (SAM) Corporation is a global sputtering target manufacturer established in 1994. For more information, please visit https://www.sputtertargets.net/.