Introduction

Silicon monoxide (SiO) is a critical material in the semiconductor industry, renowned for its excellent properties and versatility. As the demand for advanced semiconductor devices grows, understanding the benefits of SiO becomes crucial for industry professionals and enthusiasts. In this article, we explore the top 8 benefits of using silicon monoxide in semiconductors, highlighting its critical role in enhancing device performance, reliability, and efficiency.

1. Improved Electrical Properties

Silicon monoxide (SiO) is highly valued for its outstanding electrical insulation properties, which are crucial in the fabrication of semiconductor devices. When utilized as a dielectric material, SiO effectively reduces electrical leakage, thereby minimizing power loss and enhancing the overall performance of electronic components. The high dielectric constant of SiO, typically around 6, ensures that it can maintain electric fields efficiently without significant energy dissipation. This characteristic is particularly beneficial in the development of metal-oxide-semiconductor field-effect transistors (MOSFETs) and other integrated circuits, where reliable insulation is essential for device stability and longevity. Additionally, SiO’s use in capacitors and other charge storage devices helps maintain the integrity of the stored charge, crucial for memory devices.

2. Enhanced Thermal Stability

The thermal stability of silicon monoxide is a key factor in its widespread use in semiconductor applications. SiO can withstand high temperatures without decomposing or losing its structural integrity, making it ideal for environments that experience substantial thermal fluctuations. During semiconductor fabrication, processes such as thermal oxidation and annealing often subject materials to temperatures exceeding 1000°C. Silicon monoxide’s ability to maintain its properties under these conditions ensures that it supports consistent device performance and prevents thermal degradation, which is crucial for both manufacturing efficiency and the long-term reliability of the final products. In applications such as power electronics, where devices must endure high thermal loads, SiO’s stability is indispensable.

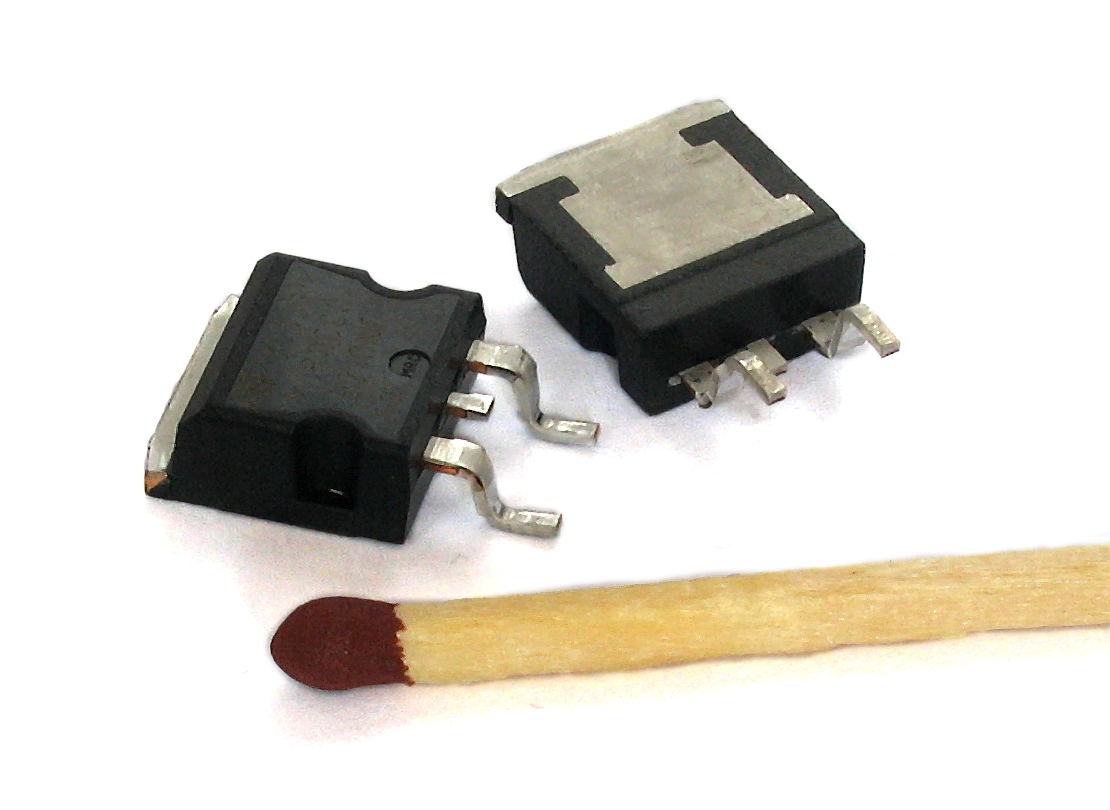

3. High-Quality Thin Films

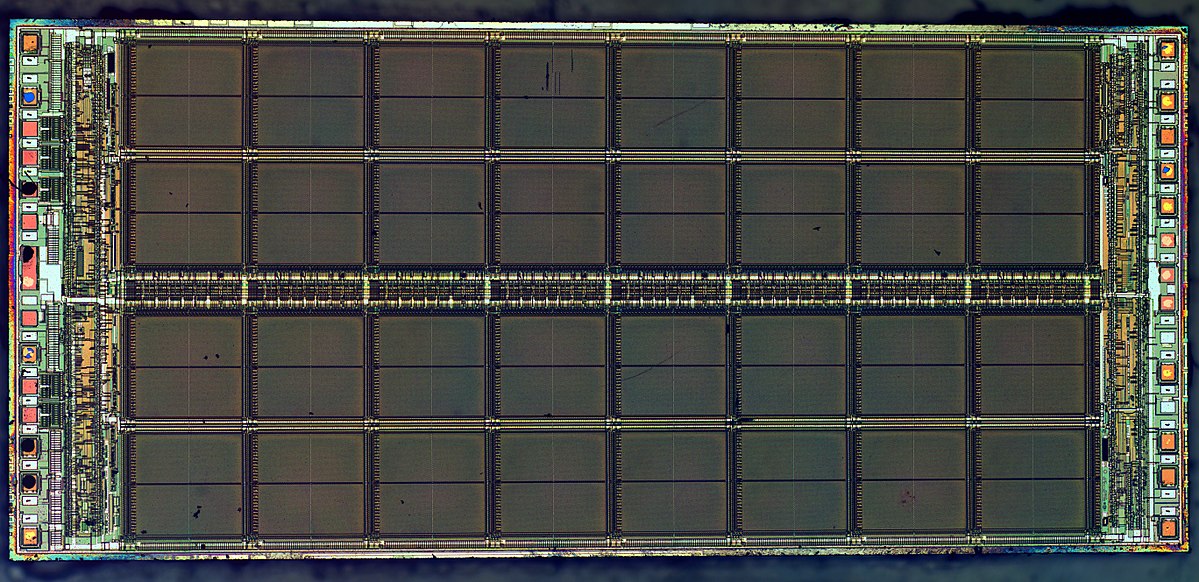

Creating high-quality thin films is fundamental in semiconductor manufacturing, and silicon monoxide excels in this area. SiO thin films can be deposited using techniques like sputtering, chemical vapor deposition (CVD), and thermal evaporation, allowing for precise control over thickness and uniformity. This uniformity is critical for producing advanced semiconductor devices, where even minor variations can lead to significant performance issues. For instance, in dynamic random-access memory (DRAM) cells, the consistent deposition of SiO as a gate oxide layer is essential for reliable operation. Furthermore, the ability to form conformal coatings makes SiO invaluable in fabricating complex three-dimensional structures used in modern integrated circuits. This is especially important in developing nanoscale transistors and other components where thin film quality directly impacts device efficiency and performance.

4. Superior Surface Passivation

Surface passivation is a process that involves creating a protective layer on semiconductor surfaces to prevent contamination and minimize the impact of surface states on electronic properties. Silicon monoxide is highly effective in this role due to its ability to form a stable and inert layer. This passivation layer reduces the density of surface states, which are electronic states that can trap charge carriers and degrade device performance. In photovoltaic cells, for example, SiO passivation significantly enhances efficiency by reducing surface recombination losses, thereby allowing more generated carriers to contribute to the electrical output. This improvement is critical in achieving high-efficiency solar cells that can compete in the renewable energy market. Similarly, in light-emitting diodes (LEDs), effective surface passivation can lead to brighter and more efficient devices.

5. Low Defect Density

The deposition of silicon monoxide typically results in films with a low defect density, a crucial factor for high-performance semiconductor devices. Defects in semiconductor materials can act as recombination centers or trap states, adversely affecting the electronic properties and overall device performance. By minimizing these defects, SiO ensures that electronic devices exhibit higher mobility, lower leakage currents, and improved reliability. In advanced semiconductor nodes, where device dimensions are scaled down to nanometer levels, the presence of even a few defects can lead to significant performance degradation. Thus, the low defect density of SiO is essential for achieving the stringent quality requirements of modern semiconductor manufacturing. This is particularly important in the production of high-speed processors and memory chips where defect minimization directly correlates with performance and yield.

6. Compatibility with Silicon

Silicon monoxide’s high compatibility with silicon, the primary material used in the semiconductor industry, simplifies its integration into existing fabrication processes. SiO can be easily grown or deposited on silicon substrates, forming high-quality interfaces that are essential for device performance. This compatibility extends to its thermal expansion coefficient, which closely matches that of silicon, thereby reducing the risk of mechanical stress and defects during thermal cycling. The ability to seamlessly integrate SiO with silicon-based devices, such as CMOS (complementary metal-oxide-semiconductor) technology, reduces manufacturing complexity and costs, making it an attractive choice for a wide range of applications. This compatibility also ensures that existing silicon fabrication infrastructure can be utilized without significant modifications, leading to cost savings and streamlined production processes.

7. Improved Optical Properties

Silicon monoxide possesses advantageous optical properties, including a high refractive index, which makes it suitable for various optoelectronic applications. In particular, its high refractive index (~1.9 at visible wavelengths) allows for efficient light manipulation, making SiO an ideal material for antireflective coatings, optical filters, and waveguides. These properties are leveraged in devices such as LEDs, lasers, and photodetectors, where precise control of light is crucial for performance. For instance, in LED manufacturing, SiO coatings can enhance light extraction efficiency, thereby increasing the brightness and efficiency of the final product. Additionally, its optical transparency in the visible and near-infrared ranges broadens its applicability in different optoelectronic systems, making it a versatile choice for applications requiring precise optical management.

8. Versatility in Applications

Silicon monoxide’s versatility extends to various semiconductor applications, from traditional electronic devices to cutting-edge technologies. In MEMS (Micro-Electro-Mechanical Systems), SiO is used as a protective coating and insulating layer, enhancing device reliability and performance. Its role in photovoltaics is also noteworthy, where it serves as an antireflective coating and passivation layer, contributing to higher solar cell efficiencies. SiO’s adaptability to various fabrication techniques and compatibility with different substrates make it suitable for innovative applications in flexible electronics, sensors, and more. This broad applicability underscores its importance as a multifunctional material in the evolving landscape of semiconductor technology, ensuring that it remains relevant as new technologies and applications continue to emerge.

Conclusion

Silicon monoxide’s unique properties and benefits make it a critical material in the semiconductor industry. Its ability to enhance electrical performance, thermal stability, and surface passivation, combined with its compatibility with silicon and versatility in various applications, ensures its continued relevance in advancing semiconductor technology. For more information or to inquire about our high-quality silicon monoxide products, please get in touch with us today.